Method of manufacturing in-mold decorative molded article

A manufacturing method and technology of molded products, applied in the fields of crafts, decorative arts, coatings, etc. for producing decorative surface effects, which can solve the problem that the setting of the gap between the display part and the decorative part of the display becomes larger and the decoration cannot be produced Molded products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

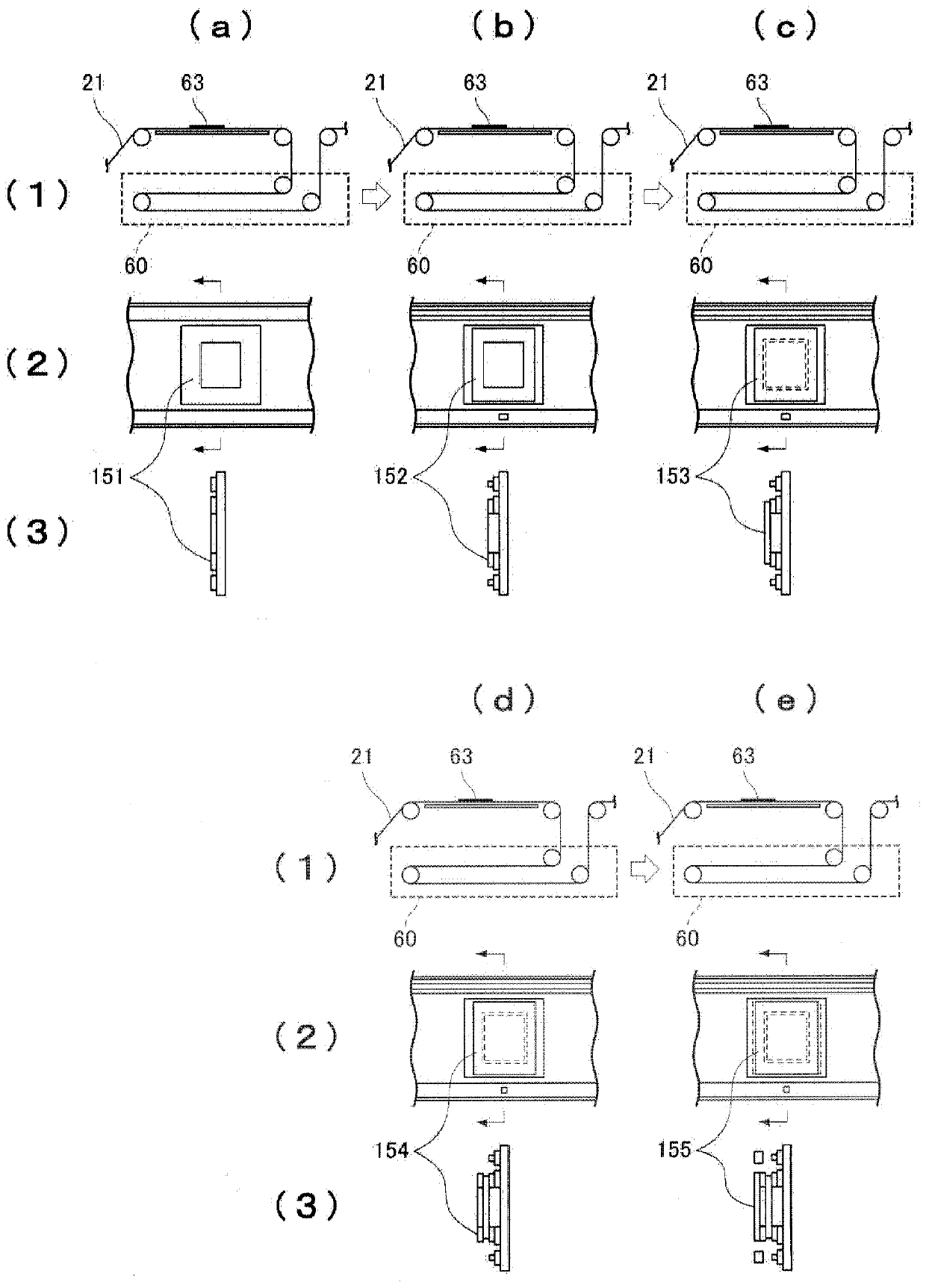

[0079] Hereinafter, the manufacturing method of the in-mold decoration molded article of this invention is demonstrated based on embodiment.

[0080] It should be noted that, for the Figure 7 ~ Figure 9 Components having the same function are assigned the same reference numerals and described.

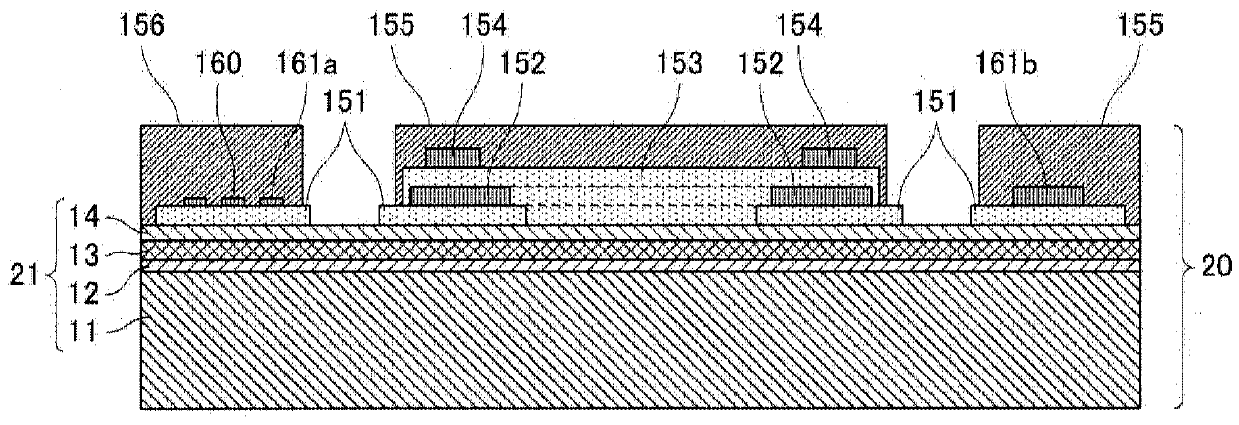

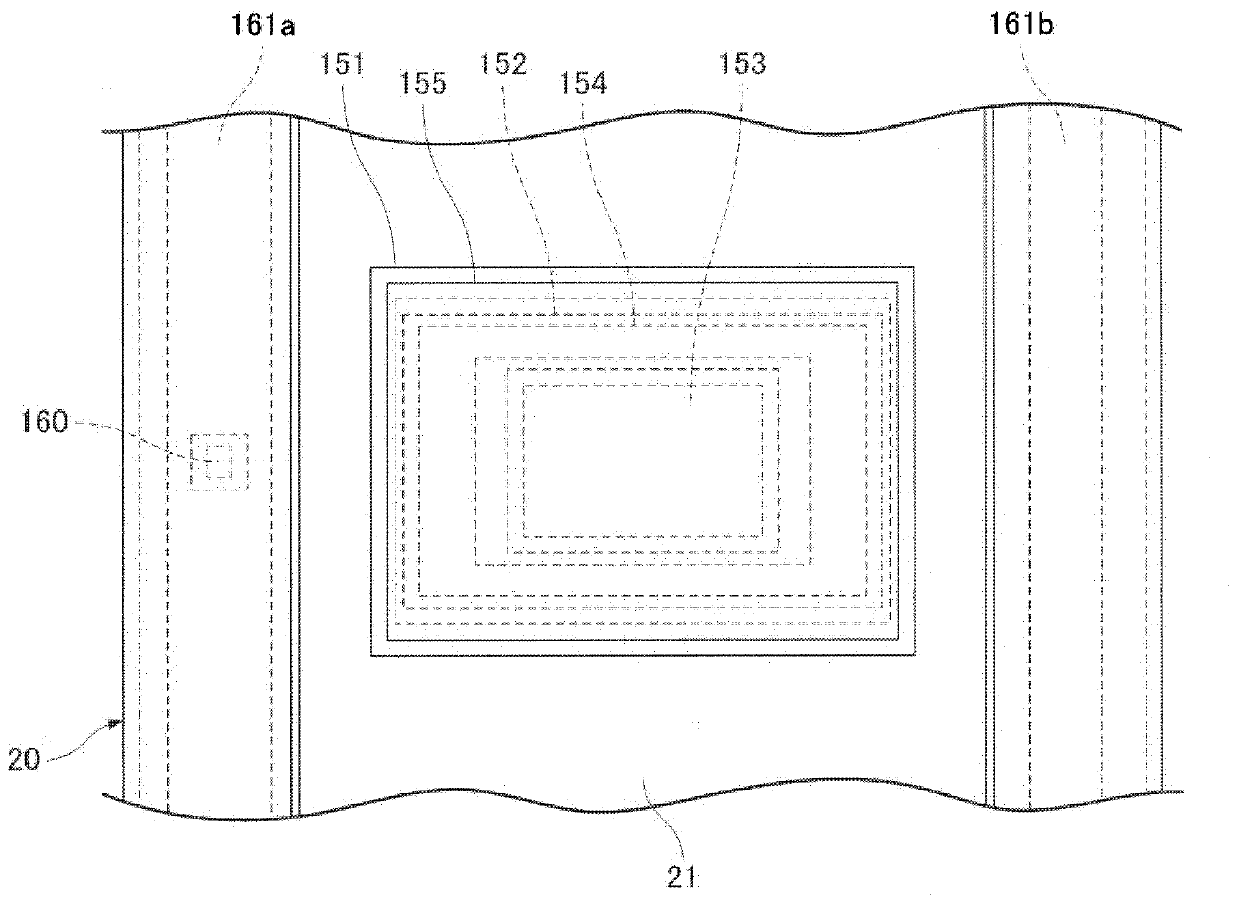

[0081] figure 1 An enlarged cross-section in the width direction of the in-mold transfer foil 20 used in the manufacturing method of the in-mold decorative molded article of the present invention is shown. figure 2 Shows its front view.

[0082] In-mold transfer foil 20 forms in-mold blank 21 by forming release layer 12 , surface protection layer 13 , and primer layer 14 on base film 11 . The release layer 12, the surface protection layer 13, and the primer layer 14 are formed by a coating method such as gravure coating and slot die coating.

[0083] The base film 11 mainly uses polyethylene terephthalate (PET: Polyethylene Terephthalate) as a material, and can also be comprised...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com