A fully automatic laser scanning tester

A laser scanning and tester technology, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of manual operation error, inconvenient use, and error prone, etc., achieve good market application value, reduce production costs, The effect of reducing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

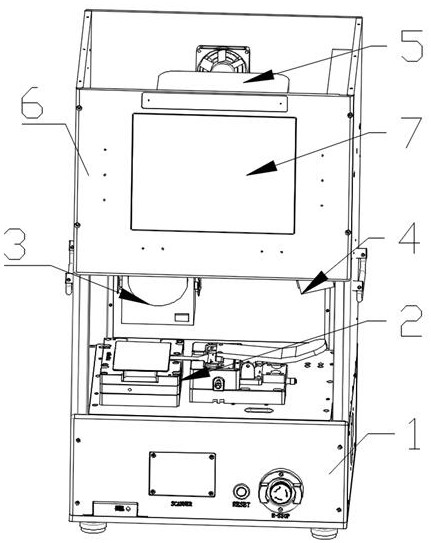

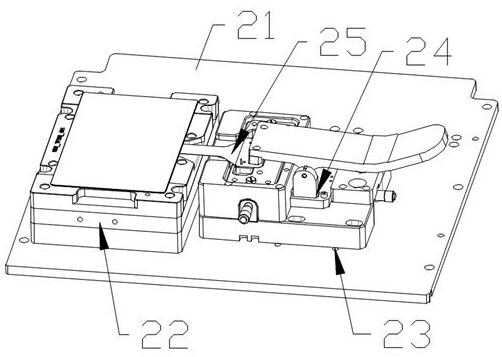

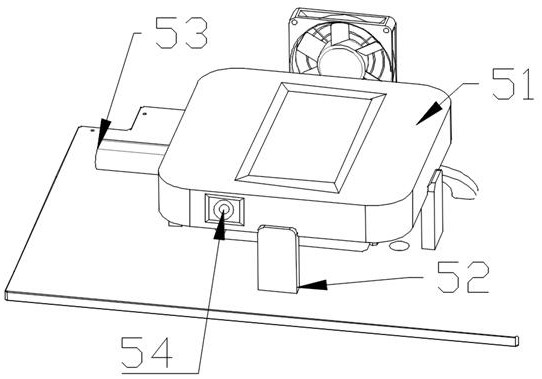

[0024] Such as Figure 1 to Figure 4 One embodiment shown: a fully automatic laser scanning tester, including a frame 1, a scanning device, a loading device 2, a first plasma fan 3, a second plasma fan 4, a testing device 5 and a receiving device, the The scanning device is set inside the frame 1, the loading device 2 is set on the frame 1, a test cover 6 is set above the loading device 2, and the bottom of the test cover 6 is set on the machine. On the frame 1, a test device 5 is arranged on the top of the test cover 6, a receiving device is arranged on the test device 5, the receiving device is connected to the test device 5, and the first plasma fan 3 is respectively arranged in the test cover 6 And the second plasma fan 4, the fixed end of the first plasma fan 3 is arranged on the rear side of the test cover 6, the fixed end of the second plasma fan 4 is arranged on the right side of the test cover 6, and the test cover 6. A display screen 7 is set on the front side, and ...

Embodiment 2

[0030] Embodiment 2 differs from the above in that the multi-port forwarder 53 is set as an intelligent HUB.

Embodiment 3

[0031]Embodiment 3 differs from the above in that a speed regulating valve, a pressure gauge and a pressure regulating button are arranged in the frame 1 respectively, the pressure regulating button is connected to the pressure gauge, and the pressure gauge is connected to the speed regulating valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com