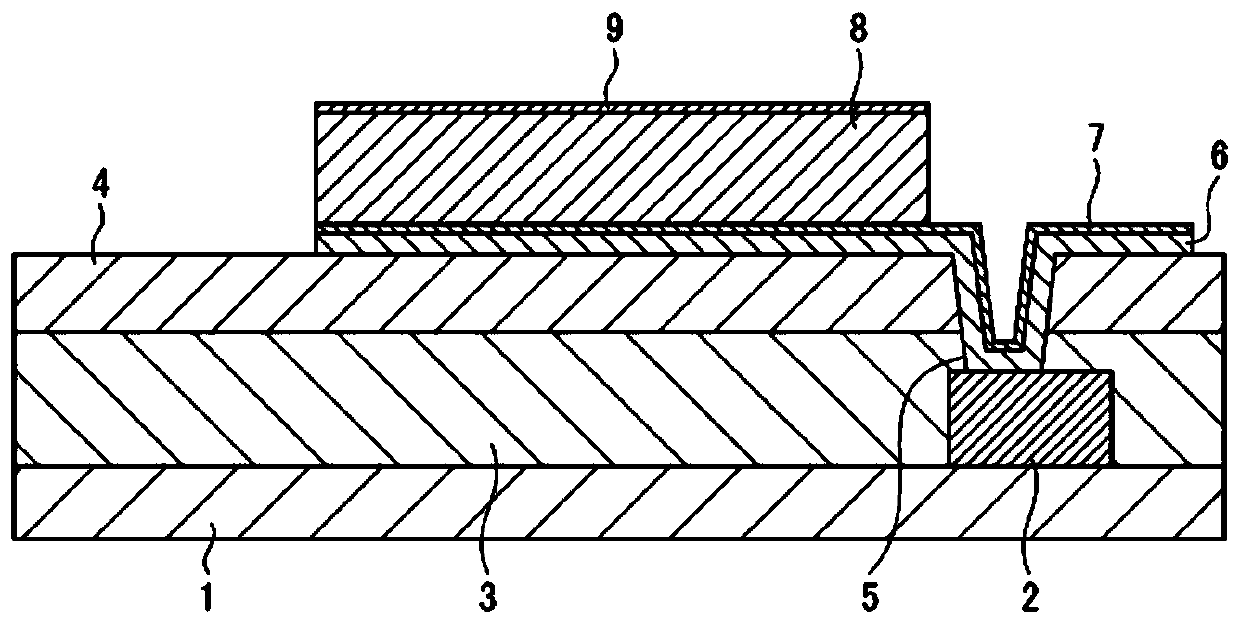

Reflective anode for organic el display and application thereof

A reflective anode and display technology, applied in the materials, circuits, conductive materials and other directions of organic semiconductor devices, can solve the problems of high contact resistance, deterioration of reflectivity, and decrease of luminous brightness of displays, and achieve high reflectivity and excellent luminous brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

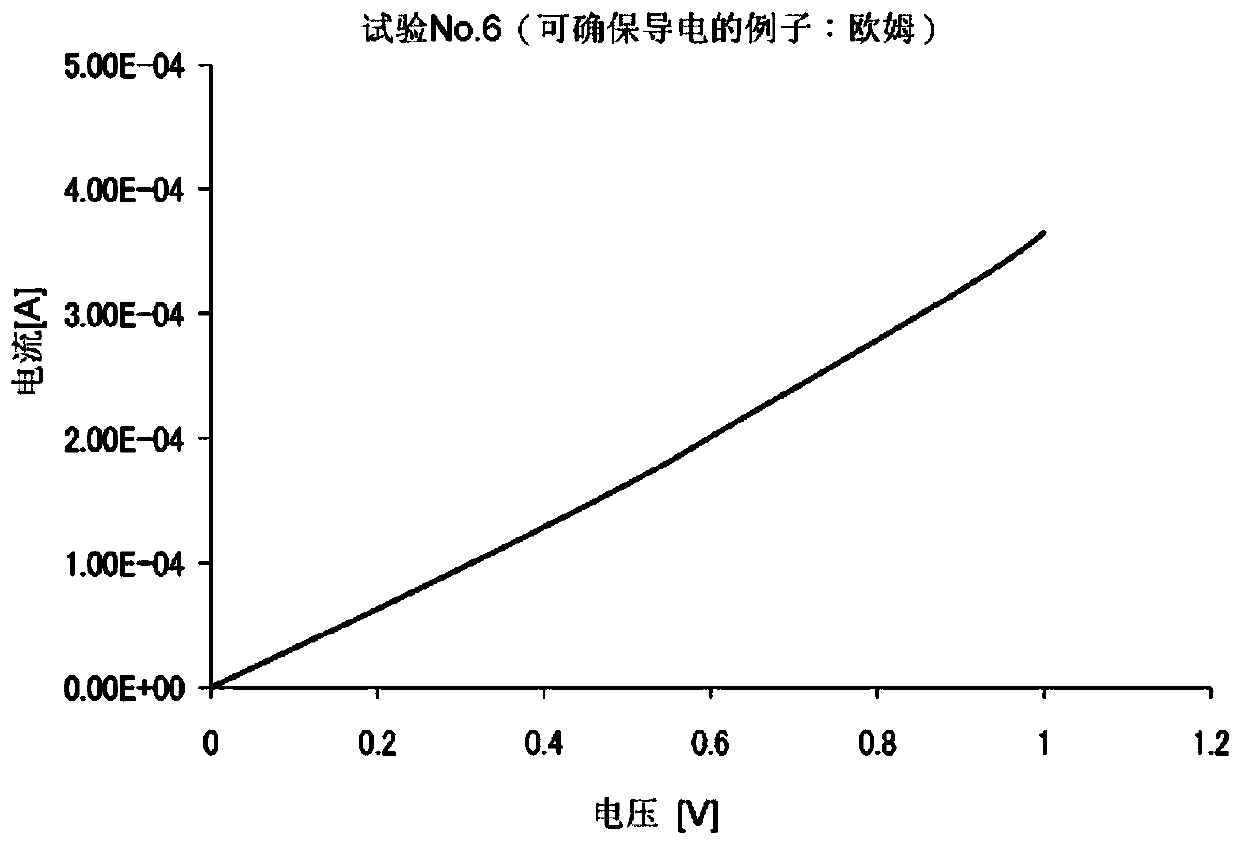

[0104] Hereinafter, examples and comparative examples are given to describe the present invention more specifically, but the present invention is not limited to these examples, and changes can be made within the scope suitable for its gist, and these are all included in the technical scope of the present invention. Inside.

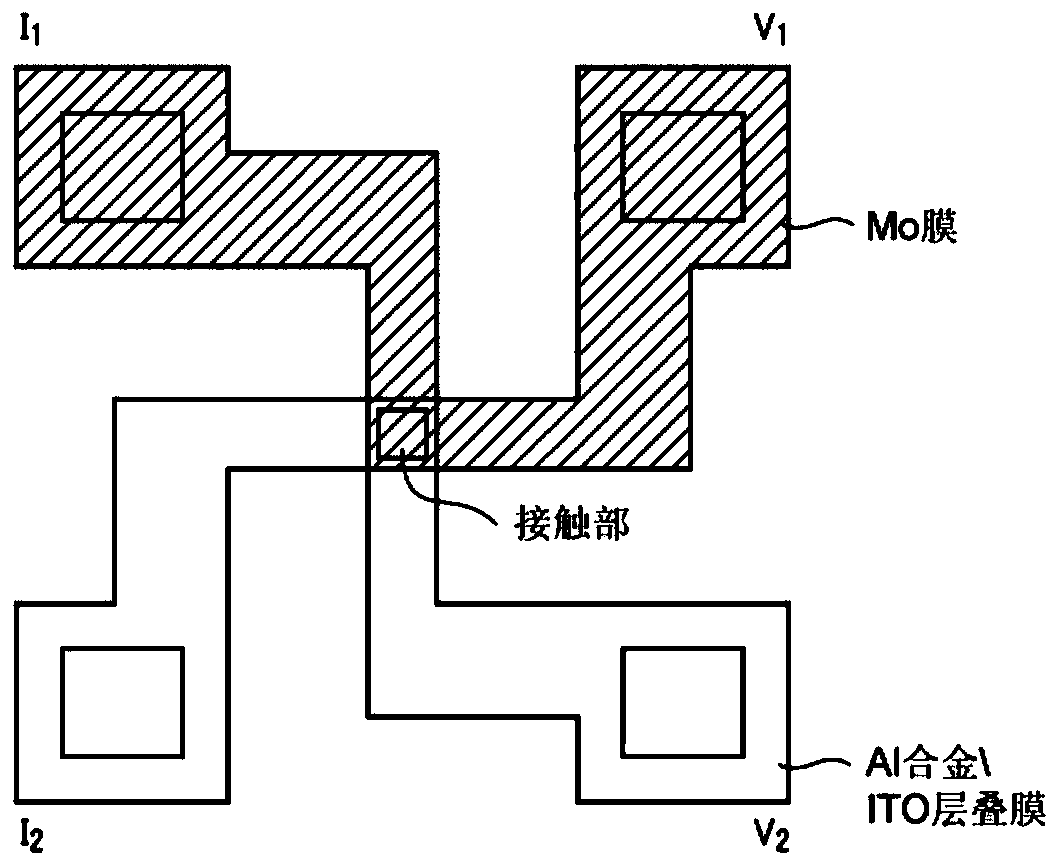

[0105] In this example, various Al alloy reflective films were used to measure the reflectance (after heat treatment), the contact resistance between the Al alloy reflective film and the oxide conductive film, the resistivity and heat resistance of the Al alloy reflective film (the thickness of the hillock). none).

[0106] Specifically, an alkali-free glass plate (thickness: 0.7 mm) was used as a substrate, and an Al-Ge alloy film (thickness: 200 nm) was produced as a reflective film on the surface thereof by a sputtering method. The chemical composition of the Al-Ge alloy film is shown in Table 1. In addition, the film forming conditions are as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com