Inverted watermill

A water wheel and suspension technology, which is applied in the field of machine tools, can solve the problems of inconvenient processing of complex valve products, and achieve good sealing performance, convenient chip removal, and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

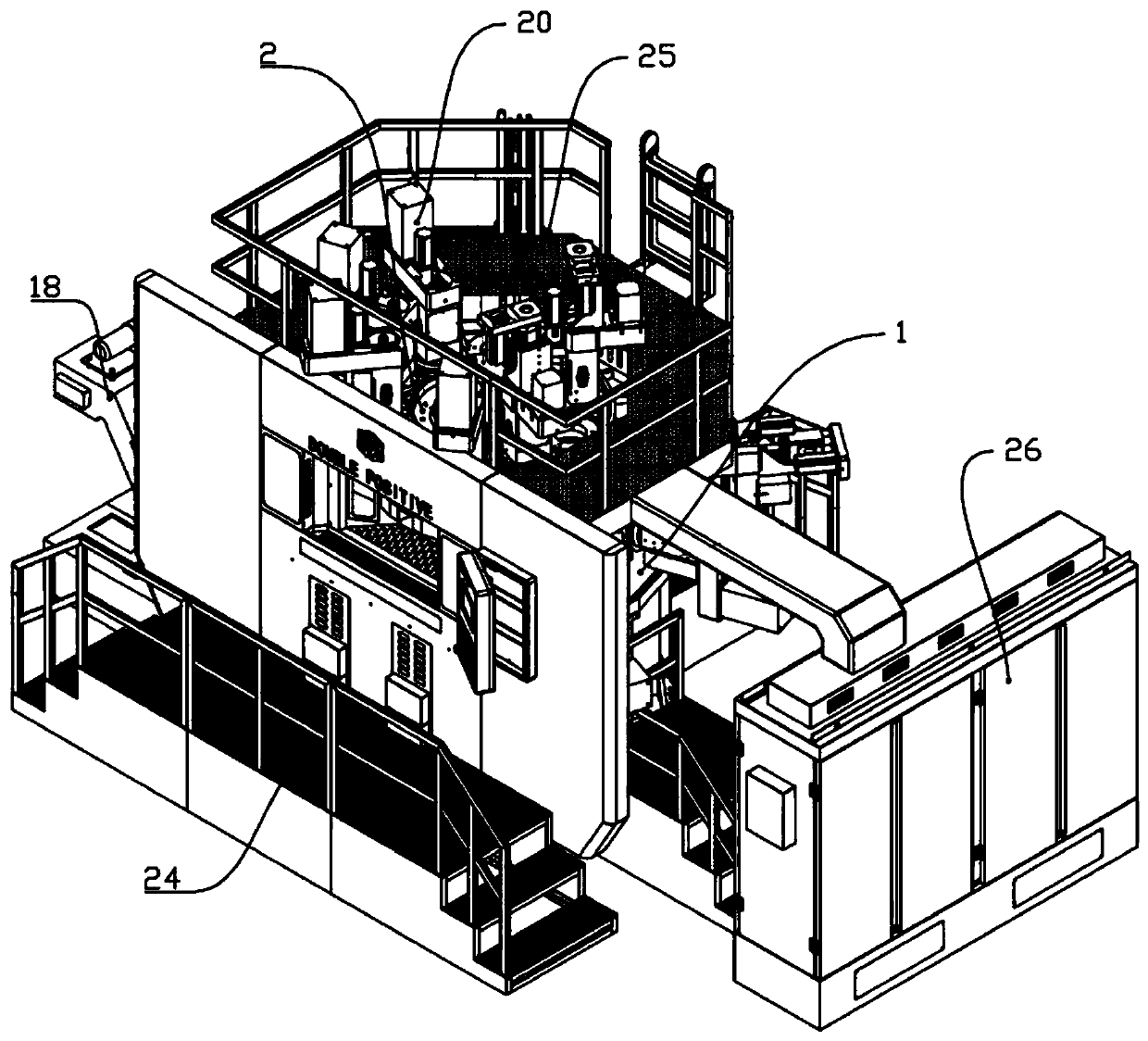

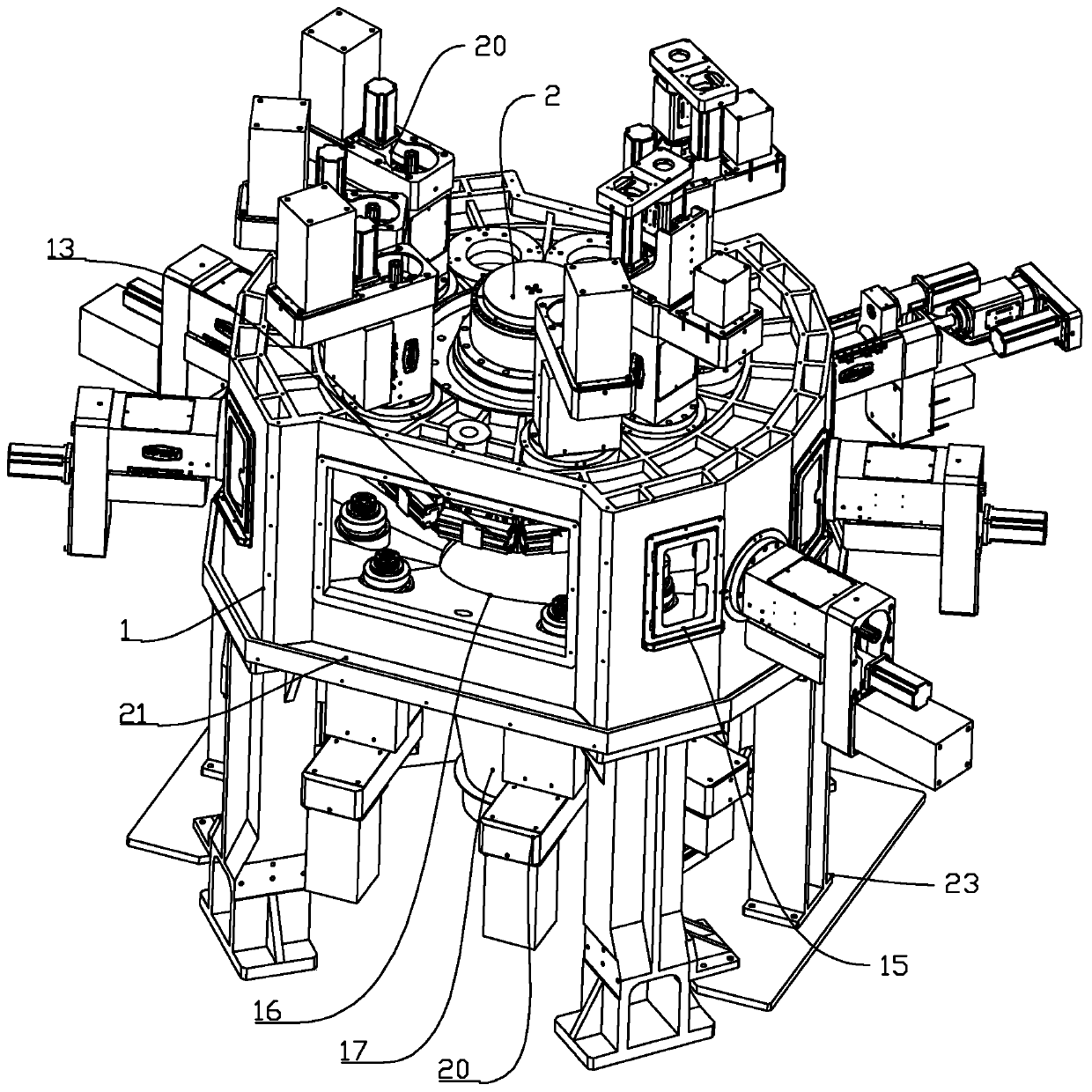

[0035] Attached below Figure 1-11 The specific embodiments of the present invention will be further described in detail.

[0036] An upside-down waterwheel.

[0037] like figure 2 As shown in the figure, it includes a bed frame 1. The bed frame 1 is provided with a hydraulic tooth-type dividing table 2 suspended in the air. The oil will flow downward due to gravity, so lubrication and oil filling are more convenient, and there is no supporting structure under the dividing table. During the machining process, the cutting fluid, chips, etc. will automatically fall into the chip removal device below due to their own gravity, which is more convenient for chip removal. Solve the processing problems of complex products;

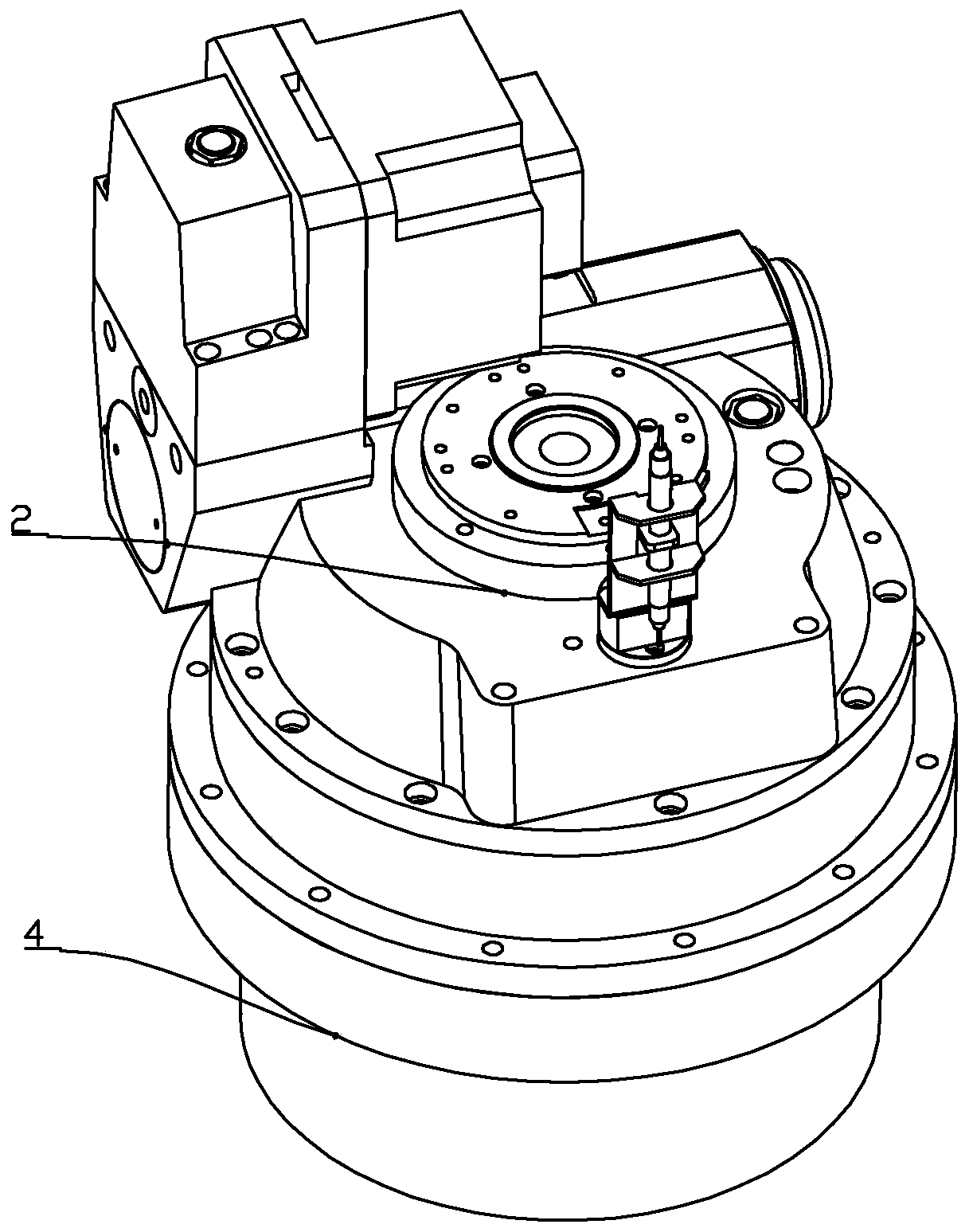

[0038] see in detail Figure 5 , The hydraulic gear-type splitting table 2 adopts a waterwheel-type ultra-precision hydraulic gear-type splitting table as the main shaft power source, which has the advantages of high stability. The outer peripheral sleeve is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com