Inner necking mouth machining mould and machining method for workpiece

A processing method and technology for processing molds, which are used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem that the heating temperature, rotation speed and rotation extrusion force of the workpiece are difficult to grasp, affect the flanging effect of the workpiece, processing efficiency and Processing quality, the workpiece is prone to twisting and bending, etc., to achieve the effect of facilitating shaping and thickness uniformity, reducing air tightness and safety, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

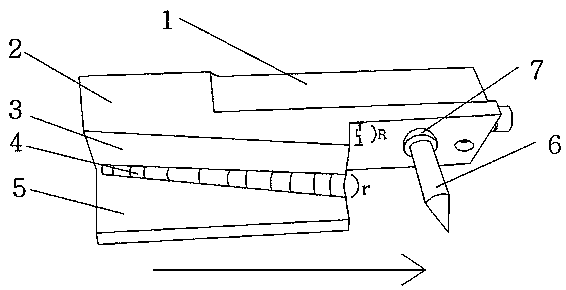

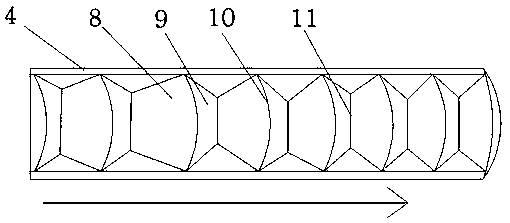

[0034] like Figure 1-2 Shown: a processing method for inner necking of workpieces, fixing the workpiece on the fixture, heating the workpiece processing end electrically, the heating temperature range is 500-1800°C, rotating the workpiece while heating, so that the workpiece and the inner necking processing mold Contact and relative movement to generate frictional heating, extrude the inner flanging of the processing end, and at the same time shape the processing end, the inner shrinkage processing mold is made of hard material, and the workpiece rotation speed is 2-15m / s, The extrusion pressure is 5-150 kg / ㎡, and the notch in the through hole is formed on the shaped workpiece, and then the workpiece is tapped to shape. The extrusion pressure is the extrusion force in the axial direction of the workpiece, or the longitudinal extrusion force perpendicular to the axial direction of the workpiece, or the lifting force of the mold on the processing end of the workpiece, or the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com