Tea fungus bean curd and production method thereof

A production method, the technology of kombucha fungus, is applied in the field of deep processing of bean products, which can solve the problems such as difficulty in innovation of tofu varieties, achieve the effects of enriching nutrition and health care functions, simple production process, and improving flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

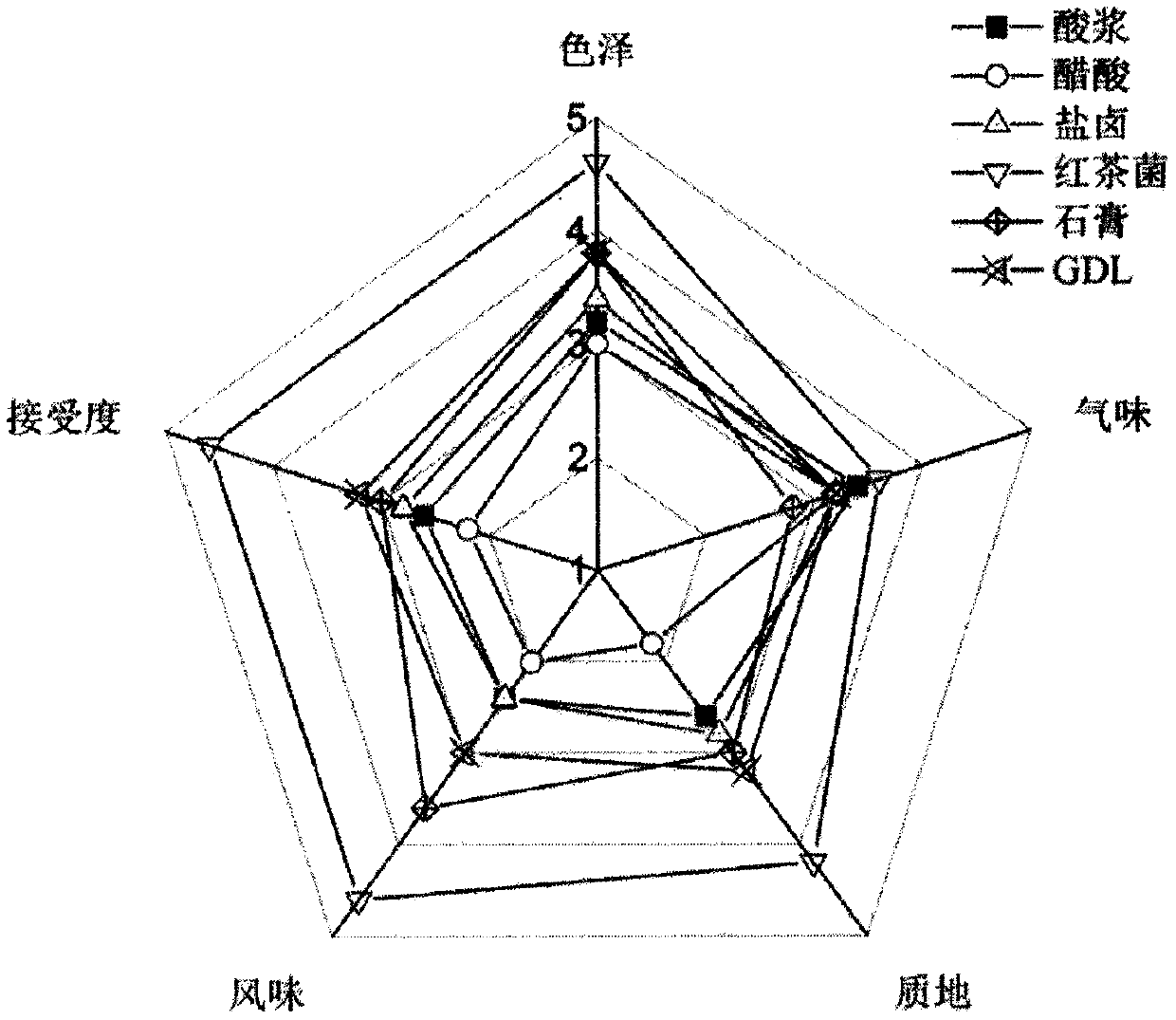

Image

Examples

Embodiment 1

[0028] (1) Boil sugar tea water containing 6wt% white granulated sugar and 0.5wt% black tea for 20 minutes, inoculate naturally fermented kombucha bacterium liquid after cooling to room temperature and ferment, stop fermentation when the pH of the kombucha bacterium liquid reaches 2.8, and obtain kombucha fungus Bacteria liquid and kombucha fungus film;

[0029] (2) dilute step (1) gained kombucha bacterium liquid with water to be 3.8 as bean curd coagulant to pH;

[0030] (3) beating the kombucha bacterial film obtained in step (1) with a pulverizer;

[0031] (4) Add 5 wt% kombucha fungus film after soybean removal, cleaning, soaking, beating, and slag removal, boil the soybean milk, and adjust the concentration of soybean milk to 9Brix;

[0032] (5) Keep the temperature of soybean milk above 85°C, add half of the total amount of kombucha bacteria liquid within 10-15 seconds, add at a uniform speed, stir well until the phenomenon of broken flowers appears, and then continue ...

Embodiment 2

[0035] (1) Boil the sugar tea water containing 6wt% white granulated sugar, 2% honey, and 1wt% green tea for 20 minutes, inoculate the kombucha bacterium liquid fermented by the starter consisting of acetic acid bacteria and saccharomyces after cooling to room temperature, and ferment the kombucha bacterium When the pH of the bacterial liquid reaches 3.0, the fermentation is stopped, and the kombucha bacterial liquid and the kombucha bacterial film are obtained;

[0036] (2) dilute step (1) gained kombucha bacterium liquid with water to be 3.8 as bean curd coagulant to pH;

[0037] (3) beating the kombucha bacterial film obtained in step (1) with a pulverizer;

[0038](4) Add 10wt% kombucha fungus film after removing impurities, cleaning, soaking, beating, and removing slag from the soybeans, boil the soybean milk, and adjust the concentration of the soybean milk to 10Brix;

[0039] (5) Keep the temperature of soybean milk above 85°C, add half of the total amount of kombucha ...

Embodiment 3

[0041] (1) Boil sugar tea water containing 10wt% sucrose and 1.5wt% black tea for 30 minutes, inoculate naturally fermented kombucha bacterium liquid after cooling to room temperature and ferment, stop fermentation when the pH of the kombucha bacterium liquid reaches 3.6, and obtain kombucha bacterium liquid and kombucha fungus film;

[0042] (2) Dilute the kombucha bacteria liquid obtained in step (1) with water to a pH of 4.0 as a tofu coagulant;

[0043] (3) beating the kombucha bacterial film obtained in step (1) with a pulverizer;

[0044] (4) Add 10wt% kombucha fungus film after removing impurities, cleaning, soaking, beating, and removing slag from the soybeans, boil the soybean milk, and adjust the concentration of the soybean milk to 11Brix;

[0045] (5) Keep the temperature of soybean milk above 85°C, add half of the total amount of kombucha bacteria liquid within 10-15 seconds, add at a uniform speed, stir well until the phenomenon of broken flowers appears, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com