Lithium battery pack thermal management system and method with dry and wet separation

A dry and wet separation and management system technology, applied in secondary batteries, battery/fuel cell control devices, circuits, etc., can solve the problems of large safety hazards, large battery damage, low heat dissipation efficiency, etc. The effect of uniform temperature and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

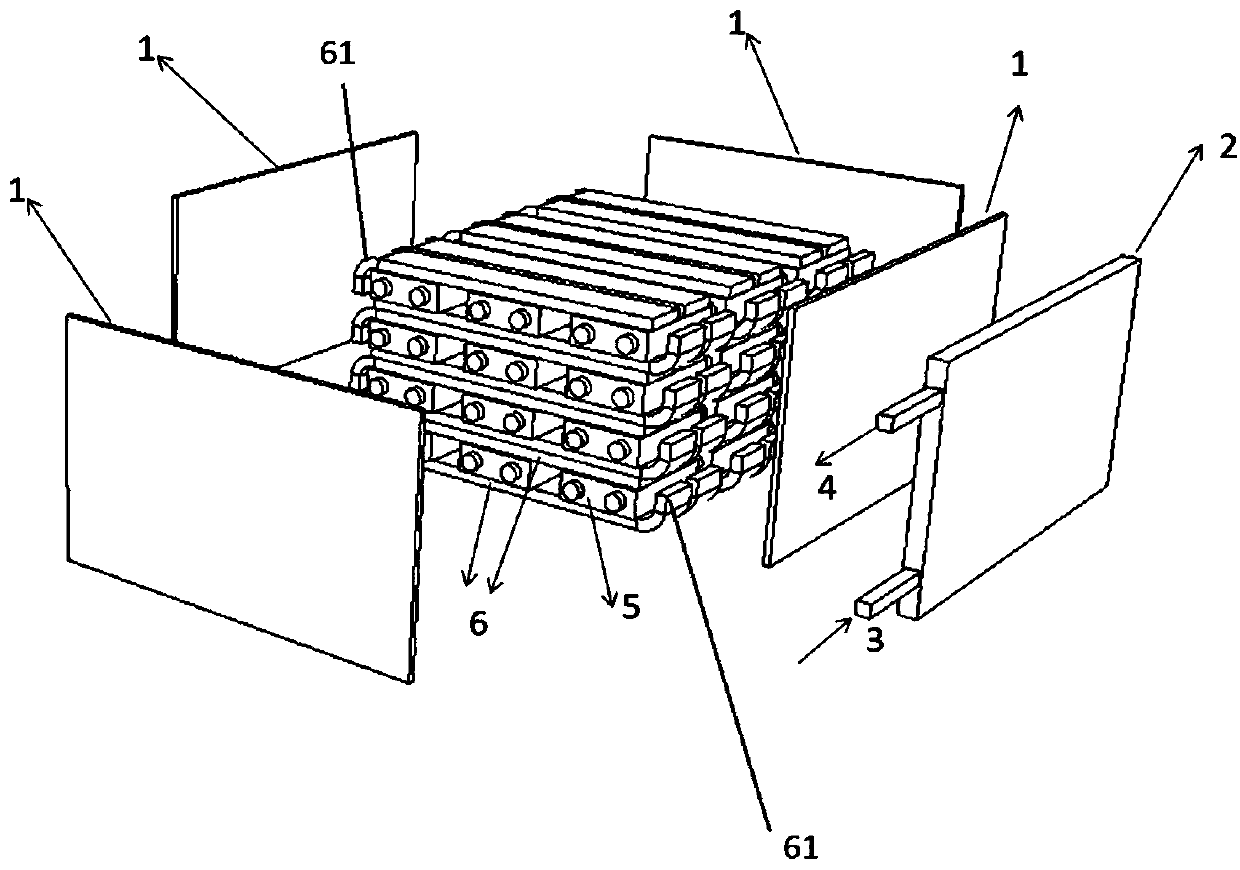

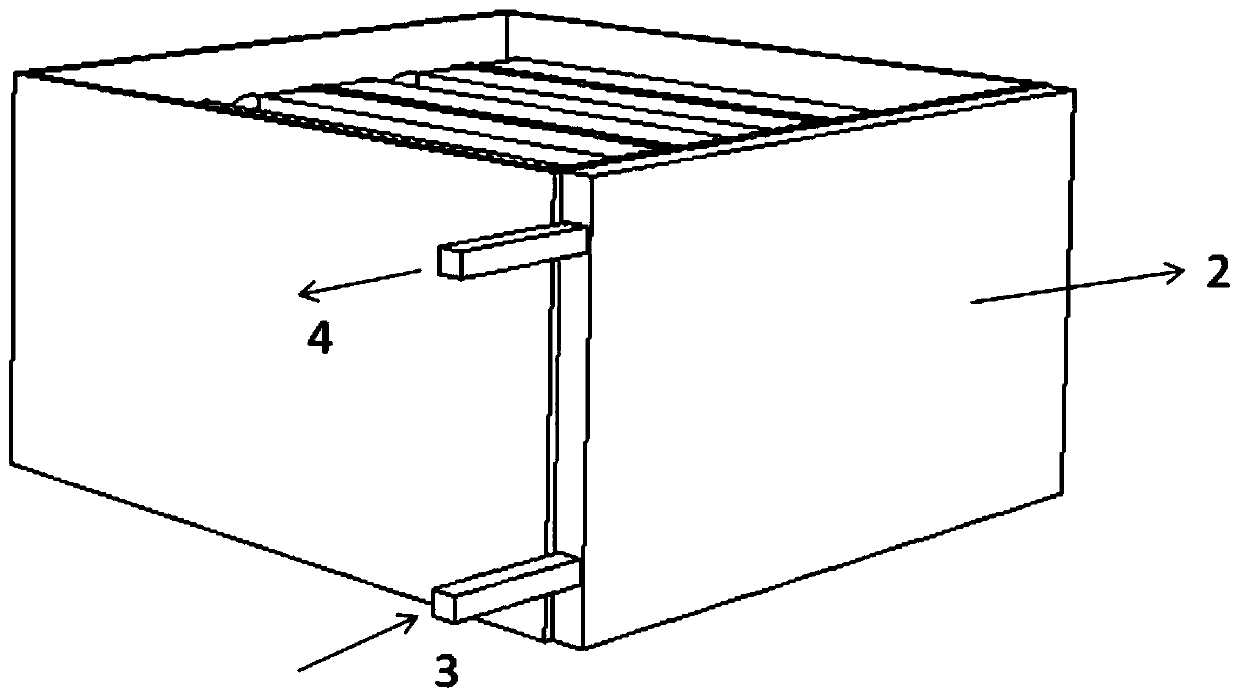

[0032] In order to understand the content of the present invention more clearly, the attached Figure 1-3 Describe in detail with specific embodiments.

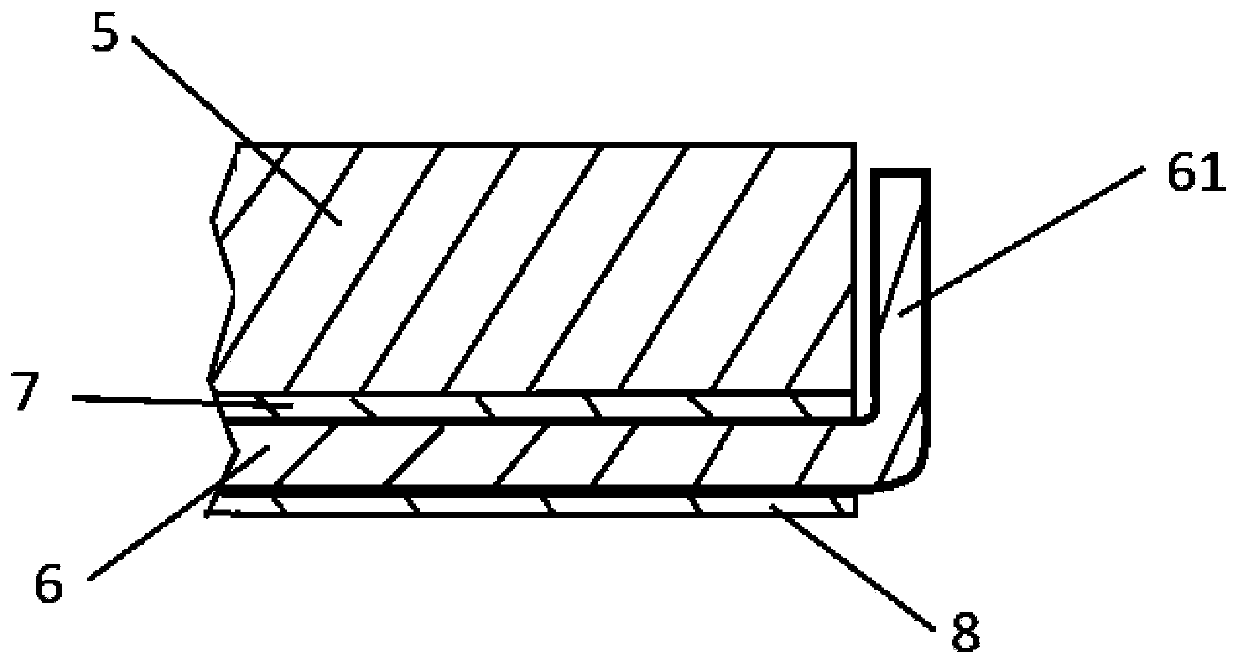

[0033] Such as Figure 1-3 As shown, a dry-wet separation battery pack thermal management system in this embodiment includes a battery pack and a liquid-cooled plate-tube heat exchanger 2 attached to the outside of the battery pack shell 1, and the battery cells in the battery pack share It is divided into four layers, and each layer has three vertical and horizontal layers. The upper and lower surfaces of the three battery units 5 in each horizontal layer are attached to two sets of micro heat pipe arrays 6 extending in the lateral direction. The micro heat pipe array 6 is a flat heat conductor with a porous structure formed by extruding metal materials. There are a plurality of mutually disconnected micro heat pipes arranged side by side. The micro heat pipes are packaged with phase change working fluid. The micro heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com