TBM anchor drilling rig real-time online monitoring system based on hydraulic system and monitoring method

A bolt drilling rig and hydraulic system technology, which is applied in the installation of bolts, drilling measurement, drilling equipment, etc., can solve the problems of unreliable monitoring methods and data, and achieve the effect of solving unreliable monitoring data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

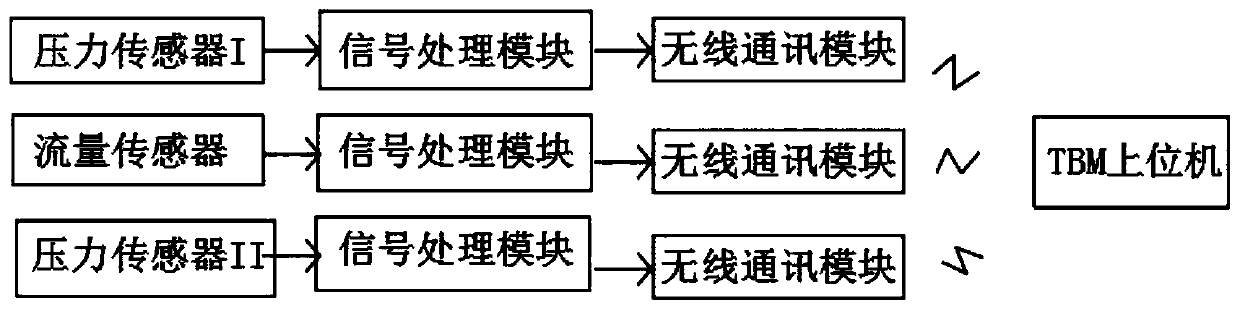

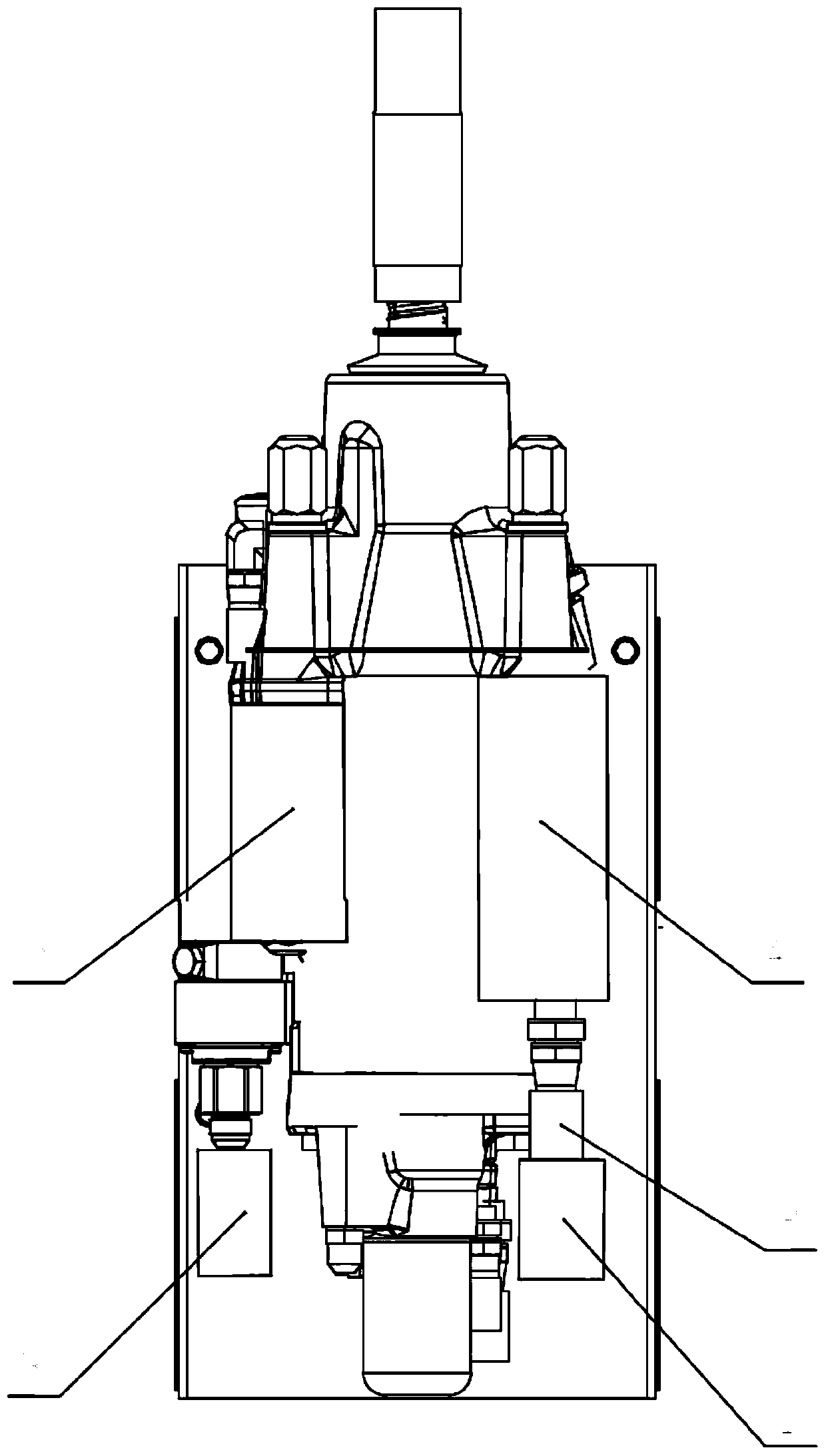

[0037] Embodiment 1: A kind of TBM bolter rig real-time online monitoring system based on hydraulic system, such as figure 1 As shown, it includes a signal acquisition module, a wireless communication module, and a TBM host computer; the signal acquisition module includes pressure sensor I2, pressure sensor II3 and flow sensor 1, and pressure sensor I2, pressure sensor II3 and flow sensor 1 are all equipped with signal Processing module, the signal processing module converts the received real-time information into digital information; and the pressure sensor I2, pressure sensor II3 and flow sensor 1 are respectively connected to a wireless communication module, such as figure 2 As shown, a pressure sensor I2 and a flow sensor 1 are provided in the hydraulic pipe 4 of the propulsion cylinder, and a pressure sensor II3 is provided in the hydraulic pipe 5 of the impact cylinder. The pressure sensor I2 detects the hydraulic pressure of the hydraulic pipe 4 of the propulsion cylin...

Embodiment 2

[0038] Embodiment 2: A monitoring method of a real-time on-line monitoring system for a TBM rock bolter based on a hydraulic system, the steps are as follows:

[0039] S1, install the pressure sensor I and the flow sensor into the hydraulic pipe of the propulsion cylinder of the TBM rocker drilling rig.

[0040] S2, measure the oil pressure and oil flow when the propulsion cylinder is not working.

[0041] The pressure sensor Ⅰ measures the oil pressure signal when the propulsion cylinder is not working. The signal processing module converts the real-time data measured by the pressure sensor Ⅰ into a digital signal and transmits it as an initial value to the TBM host computer through the wireless communication module.

[0042] The flow sensor measures the oil flow signal when the propulsion cylinder is not working, and the signal processing module converts the real-time data measured by the flow sensor into a digital signal and transmits it as an initial value to the TBM host ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com