Pre-oxidized fiber and preparation method thereof

A pre-oxidized fiber and pre-oxidized technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of pre-oxidized fiber machinability, poor tear resistance and wear resistance of downstream products, low strength of pre-oxidized fiber, and affect products. Performance and other issues, to achieve the effect of improving flame retardancy and mechanical properties, improving processability, and retaining large strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

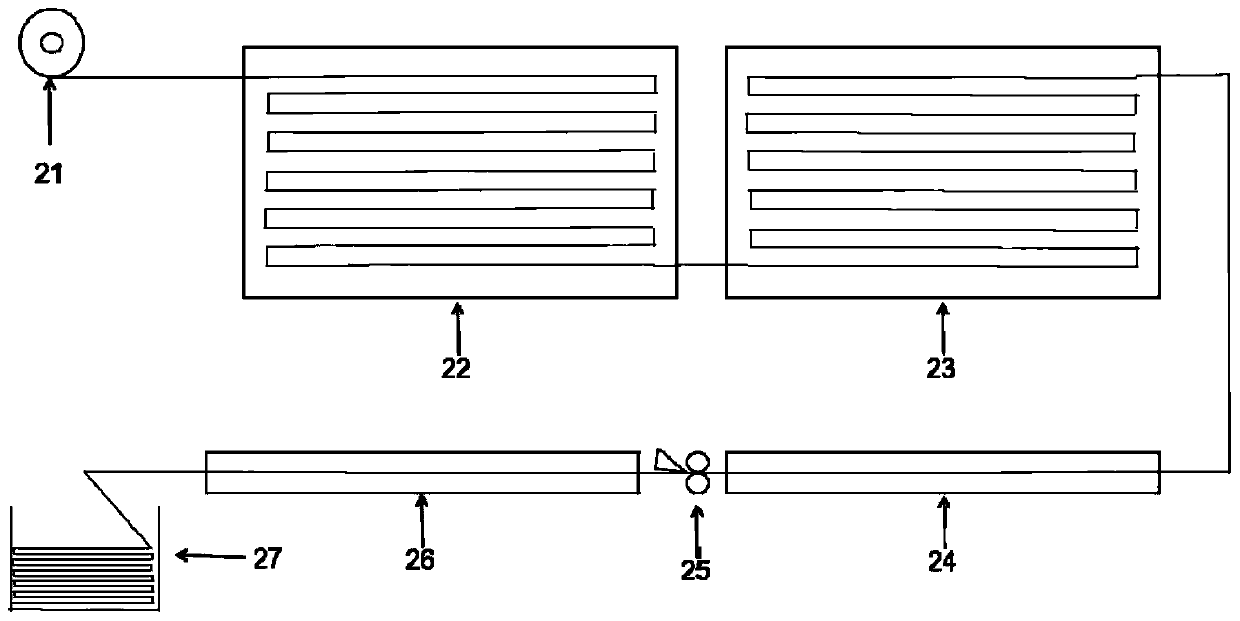

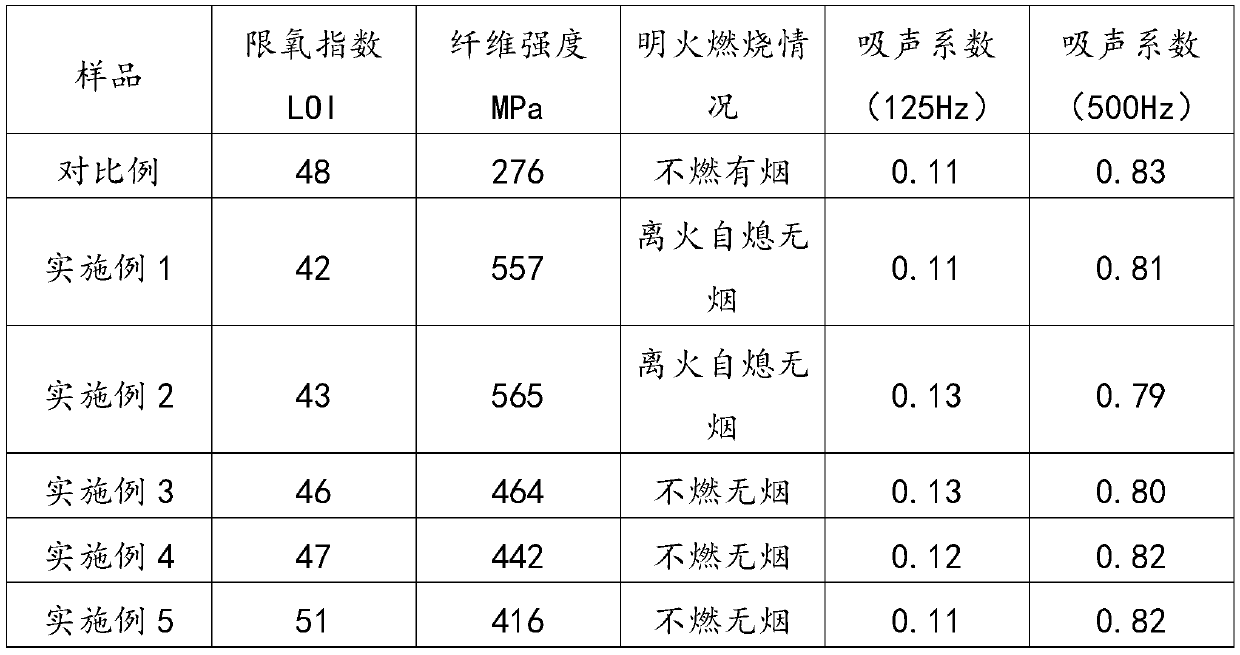

[0034] This embodiment provides a kind of preparation method of pre-oxidized fiber, such as figure 2 As shown, the polyacrylonitrile precursor enters the first pre-oxidation furnace 22 through the wire-drawing device 21. The temperature of the first pre-oxidation furnace 22 is 125° C., the applied draft is 8%, and the treatment time is 60 minutes. Then enter the second pre-oxidation furnace 23, the temperature of the second pre-oxidation furnace 23 is 235° C., the applied draft is 2%, and the treatment time is 60 minutes. The temperature of the steam drafting device 24 was 100° C., and the draft was applied at 2%. Adjust the pressure and spacing of the curling device 25 to achieve a curling effect of 3 / cm. The drying and setting device 26 is a hot air drying type, the hot air temperature is 80° C., and the drying time is 30 minutes. Then close the box and make the pre-oxidized fiber product.

[0035] The oil agent used for the raw material polyacrylonitrile precursor is ol...

Embodiment 2

[0037] This embodiment provides a kind of preparation method of pre-oxidized fiber, such as figure 2As shown, the polyacrylonitrile precursor enters the first pre-oxidation furnace 22 through the wire-drawing device 21. The temperature of the first pre-oxidation furnace 22 is 135° C., the applied draft is 7%, and the treatment time is 60 minutes. Then enter the second pre-oxidation furnace 23, the temperature of the second pre-oxidation furnace 23 is 250° C., the applied draft is 1.5%, and the treatment time is 60 minutes. The temperature of the steam drafting device 24 was 110° C., and the draft was applied at 2%. Adjust the pressure and spacing of curling device 25 to achieve a curling effect of 3 / cm. The drying and setting device 26 is a hot air drying type, the hot air temperature is 100° C., and the drying time is 20 minutes. Then close the box and make the pre-oxidized fiber product.

[0038] The oil agent used for the raw material polyacrylonitrile precursor is olei...

Embodiment 3

[0040] This embodiment provides a kind of preparation method of pre-oxidized fiber, such as figure 2 As shown, the polyacrylonitrile precursor enters the first pre-oxidation furnace 22 through the wire-drawing device 21. The temperature of the first pre-oxidation furnace 22 is 150° C., the applied draft is 6%, and the treatment time is 45 minutes. Then enter the second pre-oxidation furnace 23, the temperature of the second pre-oxidation furnace 23 is 260° C., the applied draft is 1%, and the treatment time is 45 minutes. The temperature of the steam drafting device 24 was 100° C., and the draft was applied at 2%. Adjust the pressure and spacing of curling device 25 to achieve a curling effect of 5 / cm. The drying and setting device 26 is a hot air drying type, the hot air temperature is 120° C., and the drying time is 10 minutes. Then close the box and make the pre-oxidized fiber product.

[0041] The oil agent used for the raw material polyacrylonitrile precursor is polyo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com