Bi2O2CO3/TiO2 composite material and method for photo-generated cathode protection in spoondrift splash area

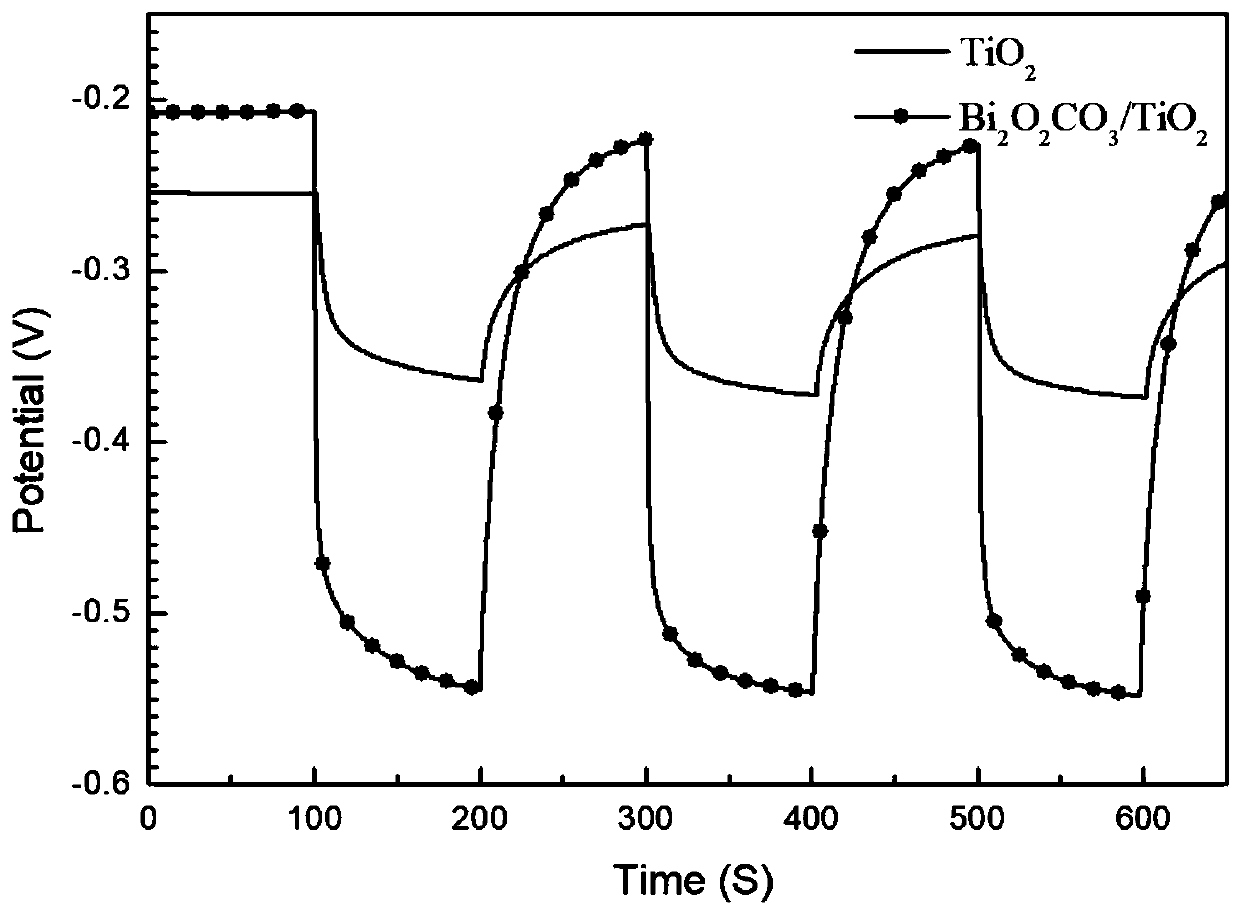

A photo-generated cathodic protection and spray technology, which is applied in metal material coating process, electrolytic coating, superimposed layer plating, etc. Excellent photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

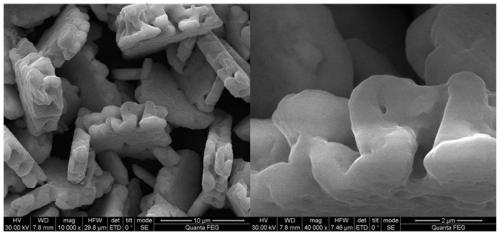

[0026] 1. Take a flat and smooth rectangular pure titanium sheet with a thickness of 0.3 mm, and ultrasonically clean it with acetone, absolute ethanol, and distilled water for 10 minutes each until the surface is reflective.

[0027] 2. Weigh 1.72g of ammonium fluoride into 50g of water, stir well, then add 450mL of ethylene glycol, stir overnight to make ammonium fluoride solution (NH 4 F solution). At room temperature, the titanium foil substrate cleaned in the above step 1 was used as the anode, and the platinum sheet was used as the cathode. 4 In solution F, anodize at 60V for 1h. Rinse with distilled water, ultrasonicate in 0.1M hydrochloric acid solution for 30min until the surface is smooth and bright, and dry for later use.

[0028] 3. Place the oxidized sample in a muffle furnace for calcination at 450°C for 2 hours, and then cool to room temperature with the furnace to obtain a TiO2 matrix.

[0029] 4. Weigh 1.0g urea, 4.9g Bi(NO 3 ) 3 ·5H 2 O to 80ml of water...

Embodiment 2

[0039] 1. Take a flat and smooth rectangular pure titanium sheet with a thickness of 0.2mm, and ultrasonically clean it with acetone, absolute ethanol, and distilled water in sequence until the surface is reflective.

[0040] 2. Weigh 0.18g of ammonium fluoride into 5g of distilled water, stir well, then add 45mL of ethylene glycol, stir overnight to make ammonium fluoride solution. At room temperature, use the titanium foil substrate cleaned in the above step 1 as the anode, and the platinum sheet as the cathode, and anodize at a voltage of 50V for 80 minutes in the above ammonium fluoride solution. Rinse with distilled water and set aside.

[0041] 3. Place the oxidized sample in a muffle furnace for calcination at 400°C for 1 hour, and then cool to room temperature with the furnace to obtain TiO 2 matrix.

[0042] 4. Weigh 5g of urea and 4.9g of bismuth nitrate pentahydrate into 80ml of double distilled water, and stir for half an hour until the raw materials are dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com