A kind of bentonite drilling fluid and preparation method thereof

A technology of bentonite and drilling fluid, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of pulping rate, chemical stability and insufficient wall protection performance, exposed ribs, wall settlement and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

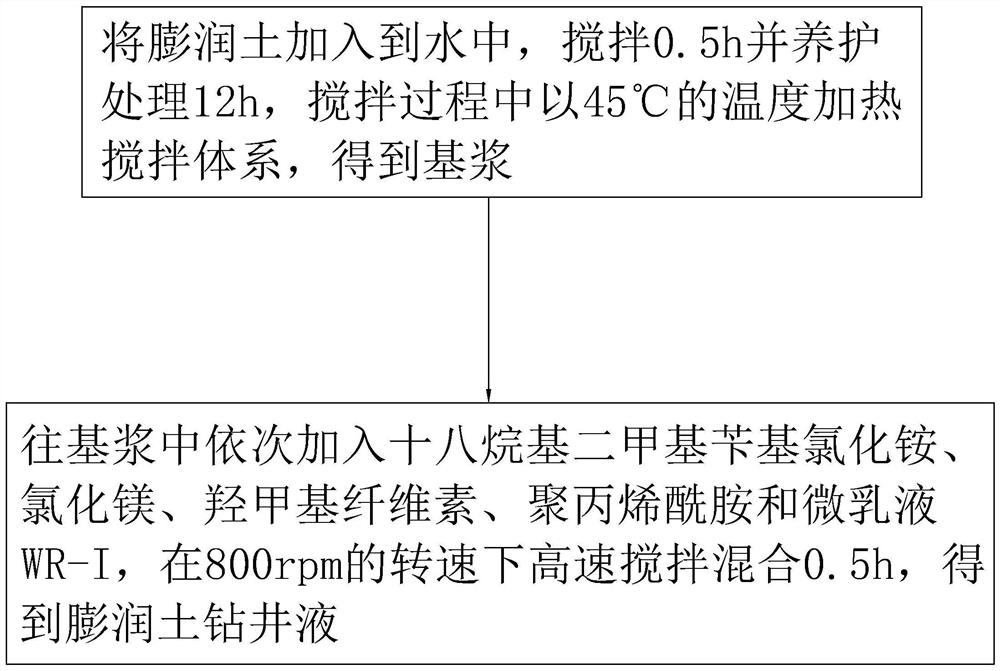

[0040] Embodiment 1: A kind of bentonite drilling fluid, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

[0041] Step 1: Add sodium-based bentonite to water, stir for 0.5 hours under heating conditions, the heating temperature is 45°C, and then perform curing for 12 hours to obtain the base slurry;

[0042] Step 2, add octadecyl dimethyl benzyl ammonium chloride, magnesium chloride, hydroxymethyl cellulose, polyacrylamide and microemulsion WR-I to the base slurry in turn, and carry out high-speed stirring and mixing at a speed of 800rpm for 0.5 h, to obtain bentonite drilling fluid.

Embodiment 2-6

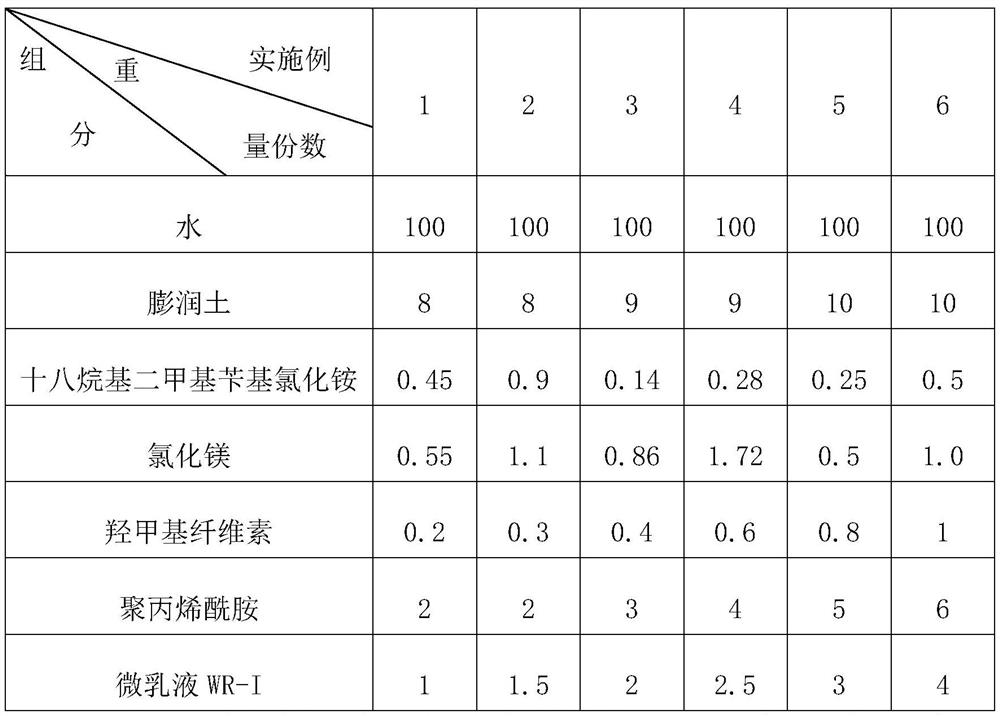

[0043] Example 2-6: a bentonite drilling fluid, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0044] Each component and parts by weight thereof in table 1 embodiment 1-6

[0045]

Embodiment 7

[0046] Embodiment 7: A kind of preparation method of bentonite drilling fluid, the difference with embodiment 1 is, in step 2, add 0.45 parts of octadecyl dimethyl benzyl ammonium chloride, 0.55 parts of Magnesium chloride, 0.2 parts of hydroxyethyl cellulose, 2 parts of polyacrylamide and 1 part of microemulsion WR-I were stirred and mixed at a high speed of 800 rpm for 0.5 h to obtain bentonite drilling fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com