A new energy vehicle battery potting material and preparation method thereof

A new energy vehicle and potting material technology, which is applied in the field of new energy vehicle battery potting materials and its preparation, can solve the problems that the low-temperature-high-temperature impact capacity of the potting material cannot be satisfied, and achieve the effect of improving the low-temperature-high temperature impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

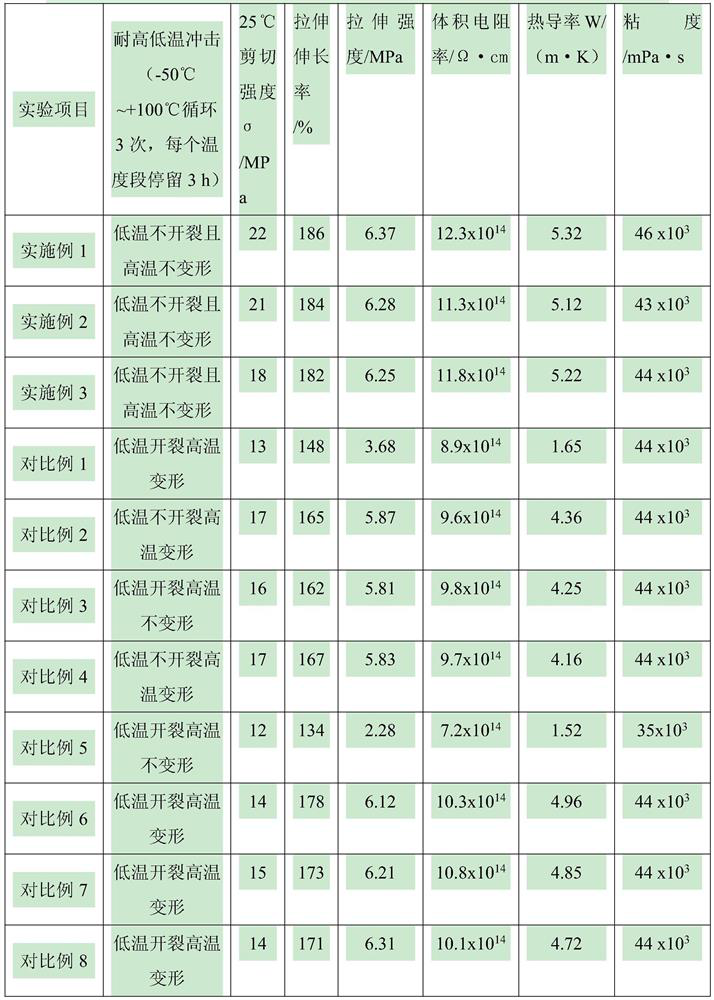

Examples

preparation example Construction

[0028] The preparation method of the new energy vehicle battery potting material comprises the following steps:

[0029] S1. Put vinyl-terminated silicone oil, hexamethyldisilazane and white carbon black into the kneader, knead for 5-6 hours, add distilled water, raise the temperature to 150-170°C, and dehydrate under the condition of vacuum degree of 0.1-0.2MPa for 20 -50min, obtain base material;

[0030] S2. After mixing the modified epoxy resin, alumina, monoplatinum catalyst and halogen-free flame retardant, ultrasonically disperse, and then disperse evenly with a grinder to obtain material I;

[0031] S3. Put the base material, peroxide vulcanizing agent and reactive diluent RZ1021 into a kneader and mix evenly, and then disperse evenly with a grinder to obtain material II;

[0032] S4. Mix material I and material II evenly, and defoam under the condition of vacuum degree of 0.08-0.1 MPa for 1-2 hours to obtain the new energy vehicle battery potting material.

Embodiment 1

[0034] A new energy vehicle battery potting material, comprising the following raw materials in parts by weight: 101 parts of modified epoxy resin, 42 parts of vinyl-terminated silicone oil, 7.4 parts of hydrogen-containing silicone oil with a mass fraction of active hydrogen of 0.5%, 26 parts of alumina, 0.2 parts of single platinum catalyst, 13.6 parts of halogen-free flame retardant, 6.4 parts of white carbon black, 2.2 parts of hexamethyldisilazane, 7.1 parts of peroxide curing agent, 0.15 parts of active diluent RZ10210 .

[0035] The modified epoxy resin is prepared according to the following process: mix 5.7 parts of silane coupling agent KH-550 and 15 parts of ethanol-water solution in parts by weight, let stand for 0.8h, then add 5.6 parts of silicon micropowder and 7.4 parts of gas phase Silica was mixed evenly, and stirred at 746r / min for 42min to obtain material a; 71 parts of AG-80 epoxy resin, 44 parts of nano-full vulcanized carboxylated nitrile rubber and mater...

Embodiment 2

[0042] A new energy vehicle battery potting material, comprising the following raw materials in parts by weight: 80 parts of modified epoxy resin, 50 parts of vinyl-terminated silicone oil, 6 parts of hydrogen-containing silicone oil with a mass fraction of active hydrogen of 0.4%, 30 parts of alumina, 0.1 parts of monoplatinum catalyst, 15 parts of halogen-free flame retardant, 5 parts of white carbon black, 3 parts of hexamethyldisilazane, 6 parts of peroxide curing agent, 0.2 parts of reactive diluent RZ10210.2 parts .

[0043] The modified epoxy resin is prepared according to the following process: mix 4 parts of silane coupling agent KH-550 and 20 parts of ethanol-water solution in parts by weight, let it stand for 0.5h, then add 8 parts of silicon micropowder and 6 parts of gas phase Mix the silica evenly, stir at 850r / min for 30min to obtain material a; mix 80 parts of AG-80 epoxy resin, 40 parts of nano-full vulcanized carboxylated nitrile rubber and material a evenly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com