Chemically strengthenable self-crystallizing glass ceramic and preparation method thereof

A glass-ceramic, self-crystallization technology, applied in glass manufacturing equipment, glass forming, glass rolling, etc., can solve problems such as increasing melting temperature, high surface compressive stress, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments.

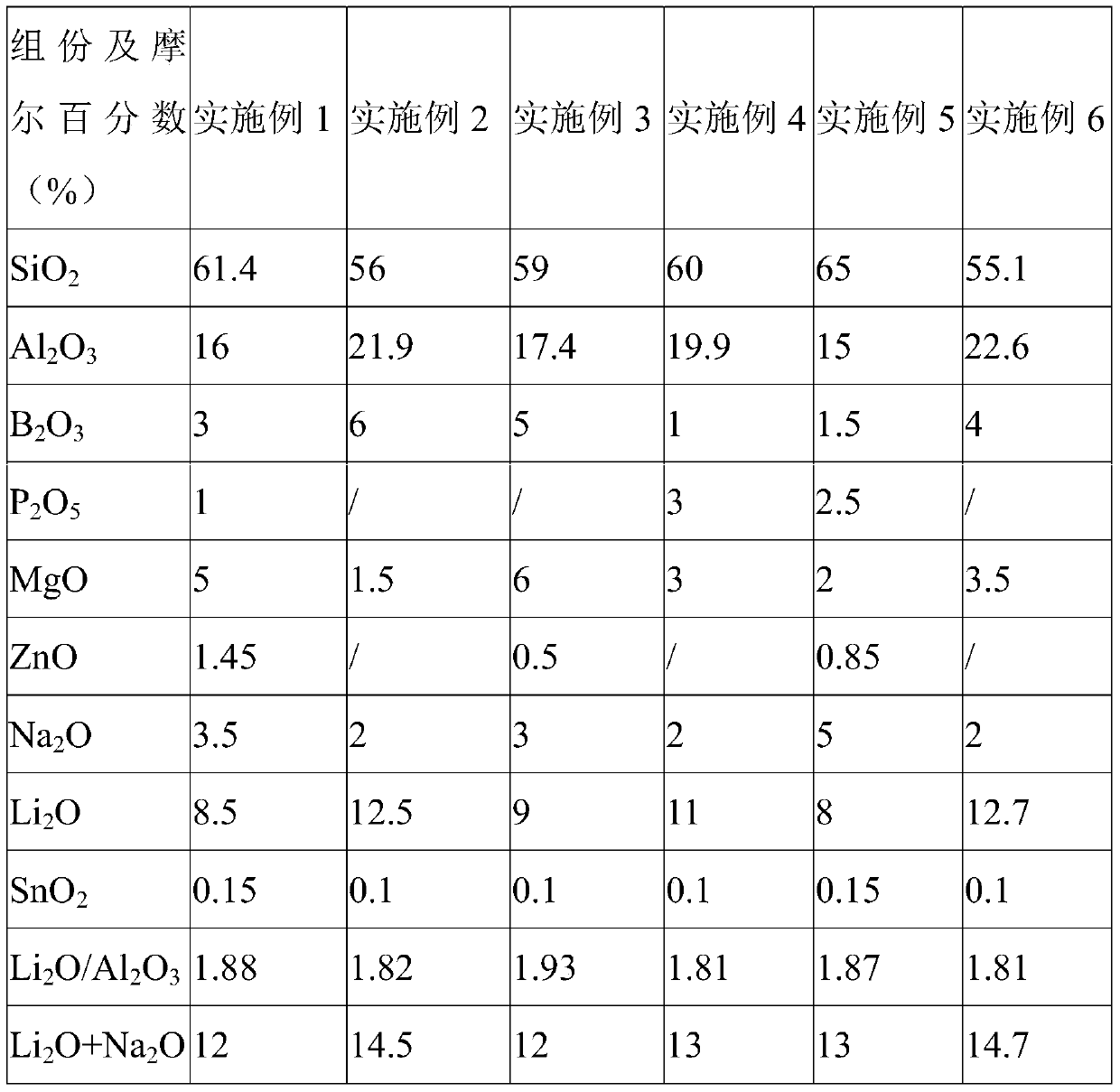

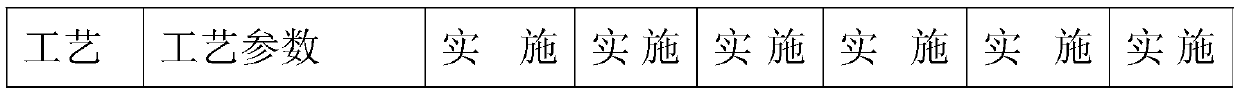

[0026] The invention provides a self-crystallizing glass ceramic that can be chemically strengthened. The glass ceramic has crystals with an average crystal size ranging from 6nm to 50nm, more preferably 10nm to 30nm; the main crystal phase of the crystal is β-quartz solid solution, haze At least one of nepheline and nepheline solid solution, the mass percentage range of the crystals in the glass ceramics is 30% to 90%, more preferably 50% to 80%, at this time, the visible light average transmittance of the 1mm thick glass ceramic The pass rate ranges from 90% to 92%. The composition of glass ceramics has the characteristics of high aluminum, high lithium and low sodium, and no ZrO 2 、TiO 2 , fluoride and other crystal nucleating agents. The composition of the glass ceramics contains 8% to 13% Li in terms of mole percentage 2 O, more preferably 9mol% ~ 12mol%, higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com