Storage device for optical fiber and cable processing

A storage device, fiber optic cable technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problem of cable loosening, cable pay-off and take-up speed mismatch, cable tearing and other issues to achieve the effect of achieving balance and adjustment, improving production and processing efficiency, and saving production line space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

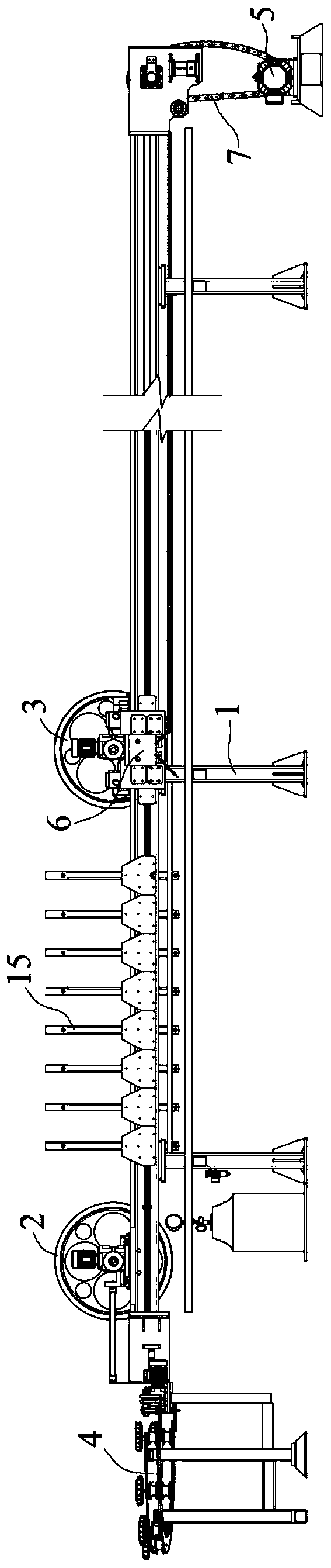

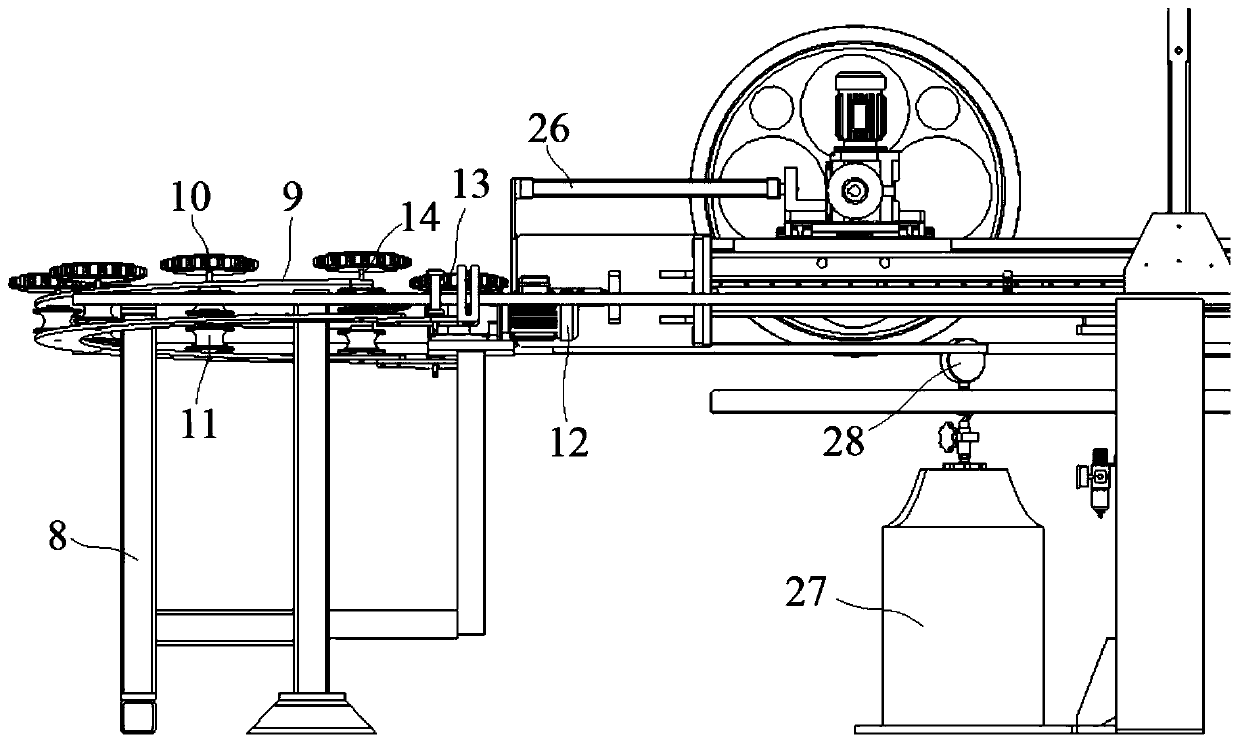

[0034] Embodiment 1: A storage device for optical fiber and cable processing, including a support 1, a first wire storage wheel set 2, a second wire storage wheel set 3, a guide mechanism 4 and a drive mechanism 5, the first wire storage wheel set 2. The second storage wheel set 3 is installed on the support 1, the guide mechanism 4 is located at one end of the support 1, and the driving mechanism 5 is arranged at the other end of the support 1;

[0035] The second wire storage wheel set 3 is movably mounted on the support 1 through a movable seat 6, and the driving mechanism 5 is connected with the movable seat 6 through a chain 7 for driving the second wire storage wheel set 3 in the Move on the support 1 along the length direction of the support 1 to approach or move away from the first line storage wheel set;

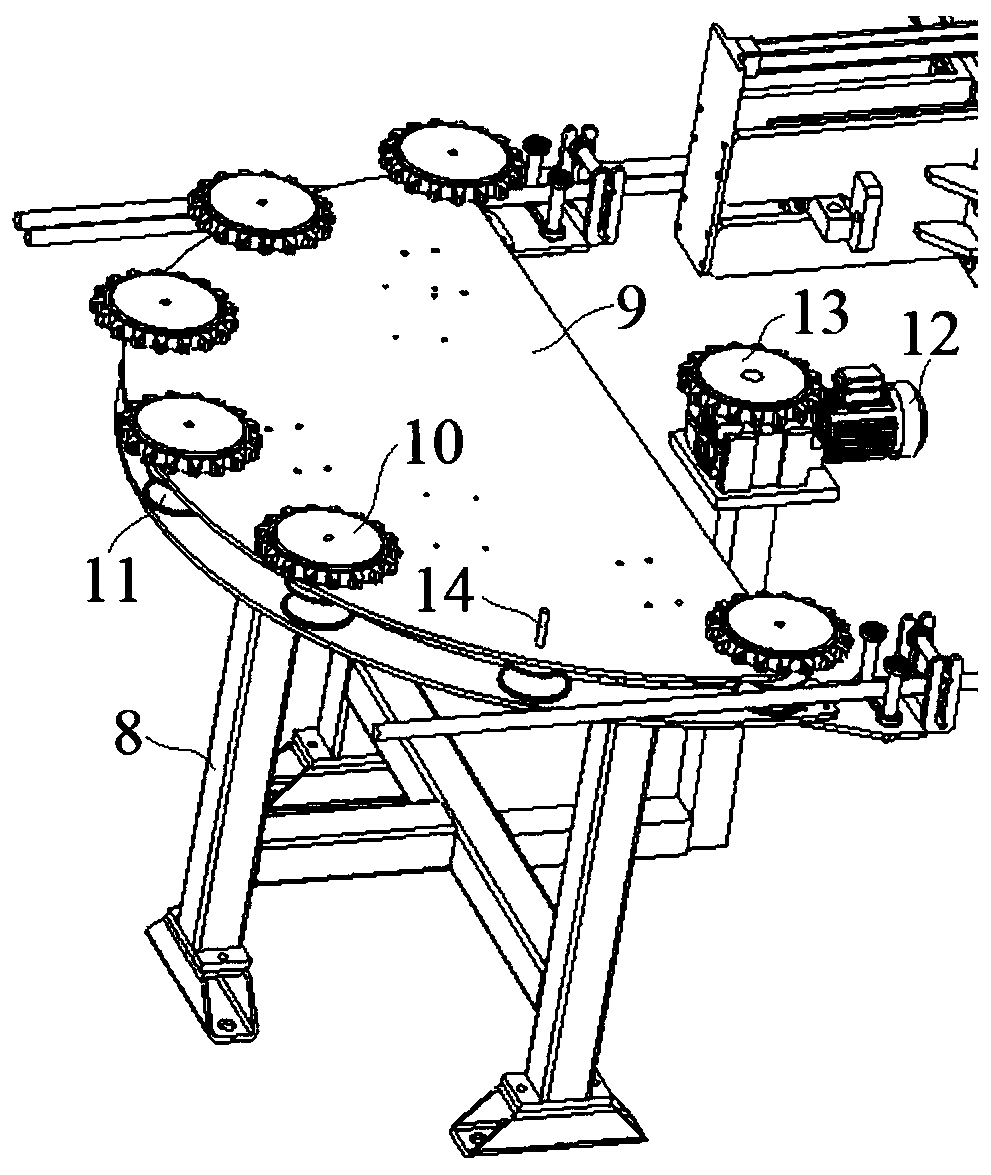

[0036] Described guiding mechanism 4 comprises base 8, the semicircle mounting plate 9 that is installed on the base 8 and some guide wheels 11 that are positioned ...

Embodiment 2

[0041] Embodiment 2: A storage device for optical fiber and cable processing, including a support 1, a first storage wheel group 2, a second storage wheel group 3, a guide mechanism 4 and a drive mechanism 5, the first storage wheel group 2. The second storage wheel set 3 is installed on the support 1, the guide mechanism 4 is located at one end of the support 1, and the driving mechanism 5 is arranged at the other end of the support 1;

[0042] The second wire storage wheel set 3 is movably mounted on the support 1 through a movable seat 6, and the driving mechanism 5 is connected with the movable seat 6 through a chain 7 for driving the second wire storage wheel set 3 in the Move on the support 1 along the length direction of the support 1 to approach or move away from the first line storage wheel set;

[0043] Described guiding mechanism 4 comprises base 8, the semicircle mounting plate 9 that is installed on the base 8 and some guide wheels 11 that are positioned at the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com