Granulated feed producing and processing equipment and method

A technology for processing equipment and pellet feed, which is applied in the field of pellet feed production and processing equipment, can solve the problems that products are not graded and screened, product quality cannot be guaranteed, and equipment is a single equipment process, so as to facilitate cleaning and maintenance, improve impurity removal effect and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

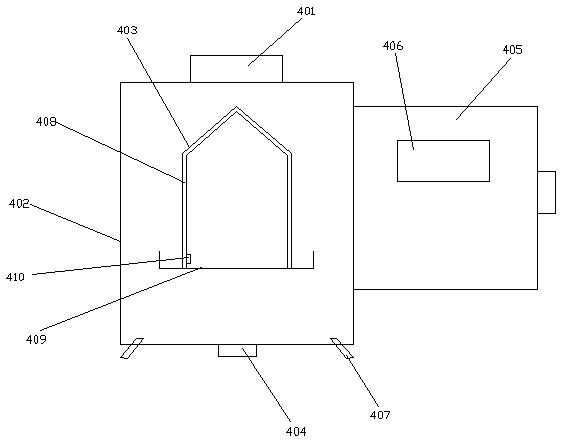

[0050] as attached figure 1 As shown, a pellet feed production and processing equipment includes a raw material receiving system, a crushing system, a mixer 8, a pelletizing system and a quantitative packaging system;

[0051] The raw material receiving system includes a feeding device 1, a quantitative device 2, a mixing tank 3, an impurity removal device 4 and a dust removal device 5. The feeding device 1 is connected to the quantitative device 2, the quantitative device 2 is connected to the mixing tank 3, and the mixing tank 3 is connected to the impurity removal device. 4 are connected through the first hoist 13, and the impurity removal device 4 is connected with the dust removal device 5;

[0052] The pulverizing system includes a pulverizer 6 and an ozone generator 7. The pulverizer 6 and the dust removal device 5 are connected through a second hoist 14. The ozone generator 7 is installed on the side of the pulverizer 6. The ozone generator 7 is used to inject air into...

Embodiment 2

[0067]Based on the above-mentioned embodiment 1, the difference of this embodiment is that the upper ends of the first feeding hopper 101 and the second feeding hopper 102 are provided with an anti-blocking device 104, and the anti-blocking device 104 is a square frame, and the distribution in the square frame is vertical The intersecting beams and longitudinal beams and the square frame allow different materials to be poured into the dosing device 2, which can be dispersed and entered, the feeding hopper is not easy to block, and the feeding is smooth, which improves the efficiency of feed production and processing and saves labor costs.

[0068] The inner walls of the pulverizer 6, the mixer 8, and the granulator 11 are all equipped with a sound insulation layer 116, which plays the role of noise reduction and noise reduction, protects the health of operators, and reduces noise pollution to the external environment at the same time. For acoustic cotton, the density of sound-a...

Embodiment 3

[0072] Based on the foregoing embodiments, a pellet feed production and processing method comprises the following steps:

[0073] (1) Material receiving, quantitative mixing ratio;

[0074] (2) Remove impurities and dust from materials;

[0075] (3) The material is crushed, and the crushing fineness is preferably 80-120 mesh;

[0076] (4) Mix the crushed materials, and spray grease by spraying;

[0077] (5) Refining and tempering the mixed materials;

[0078] (6) After the material is tempered, it is granulated, and after granulation, it is dried and cooled;

[0079] (7) Particle grade screening, quantitative packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com