Large-size silicon carbide wafer diamond wire cutting machine tool

A silicon carbide crystal and diamond wire technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve the problems of unstable processing quality and insufficient cutting wire length, and achieve simple structure, stable and reliable processing quality, Create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

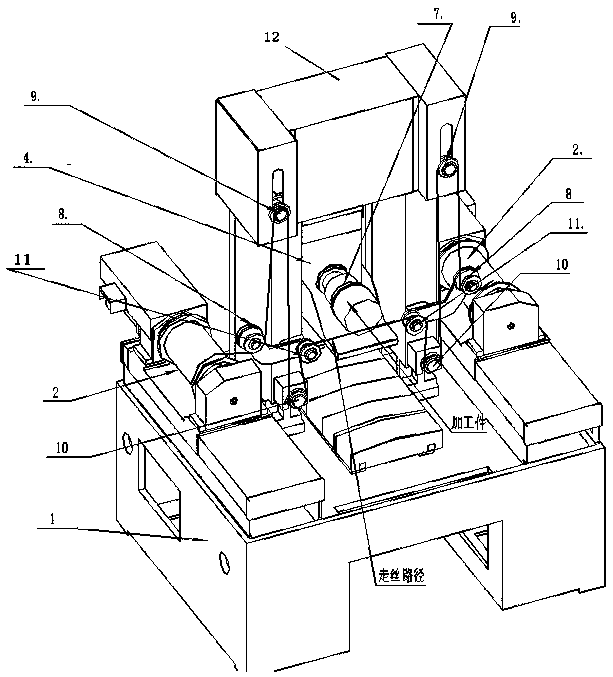

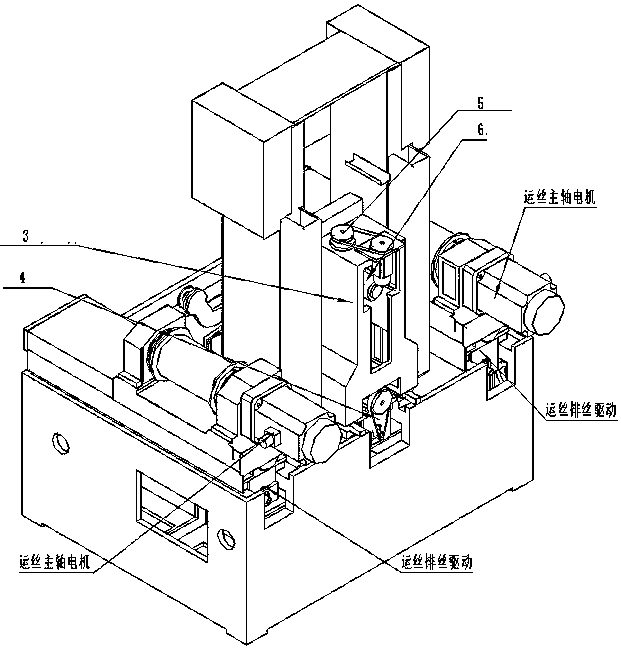

[0019] Such as Figure 1-2 shown.

[0020] A large-size silicon carbide wafer diamond wire cutting machine tool, which includes a base 1, a door-shaped column 12 is installed in the center of the base 1, and a guide wire assembly is installed on the door-shaped column 12, and the guide wire assembly includes symmetrically arranged transition guide wheels 8 , tension pulley 9, tension detection wheel 10 and capstan pulley 11, the structure of each part in the guide wire assembly is all identical with prior art, can directly be contained on the lathe of the present invention to relevant parts on the existing equipment, as figure 1 shown. The base 1 on both sides of the door-shaped column 12 is respectively equipped with a wire transporting part 2, and the wire transporting part 2 is generally composed of a wire transporting spindle motor and a wire drum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com