Submerged-arc welding pipe internal burr removal device and method

A submerged arc welded pipe and cleaning device technology, which is applied in the field of submerged arc welded pipe production, can solve the problems of plastic deformation, grinding wheel damage and pipe material, and difficult positioning of scrapers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

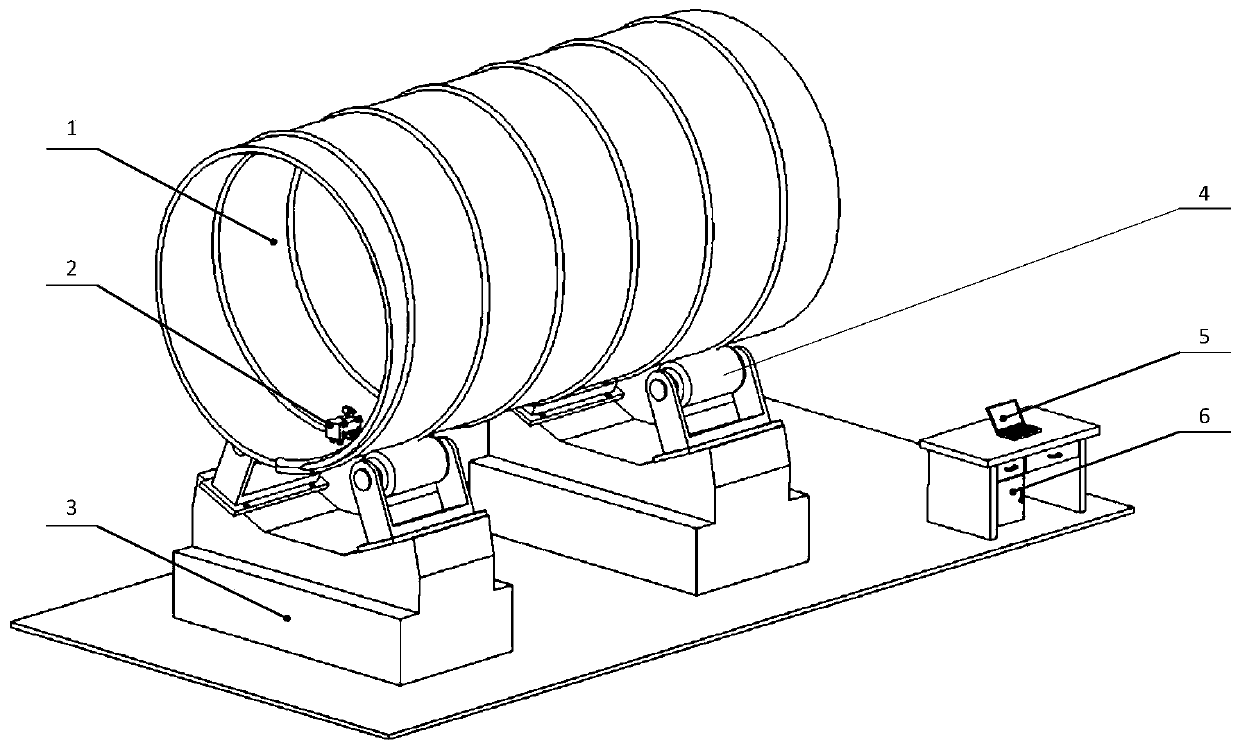

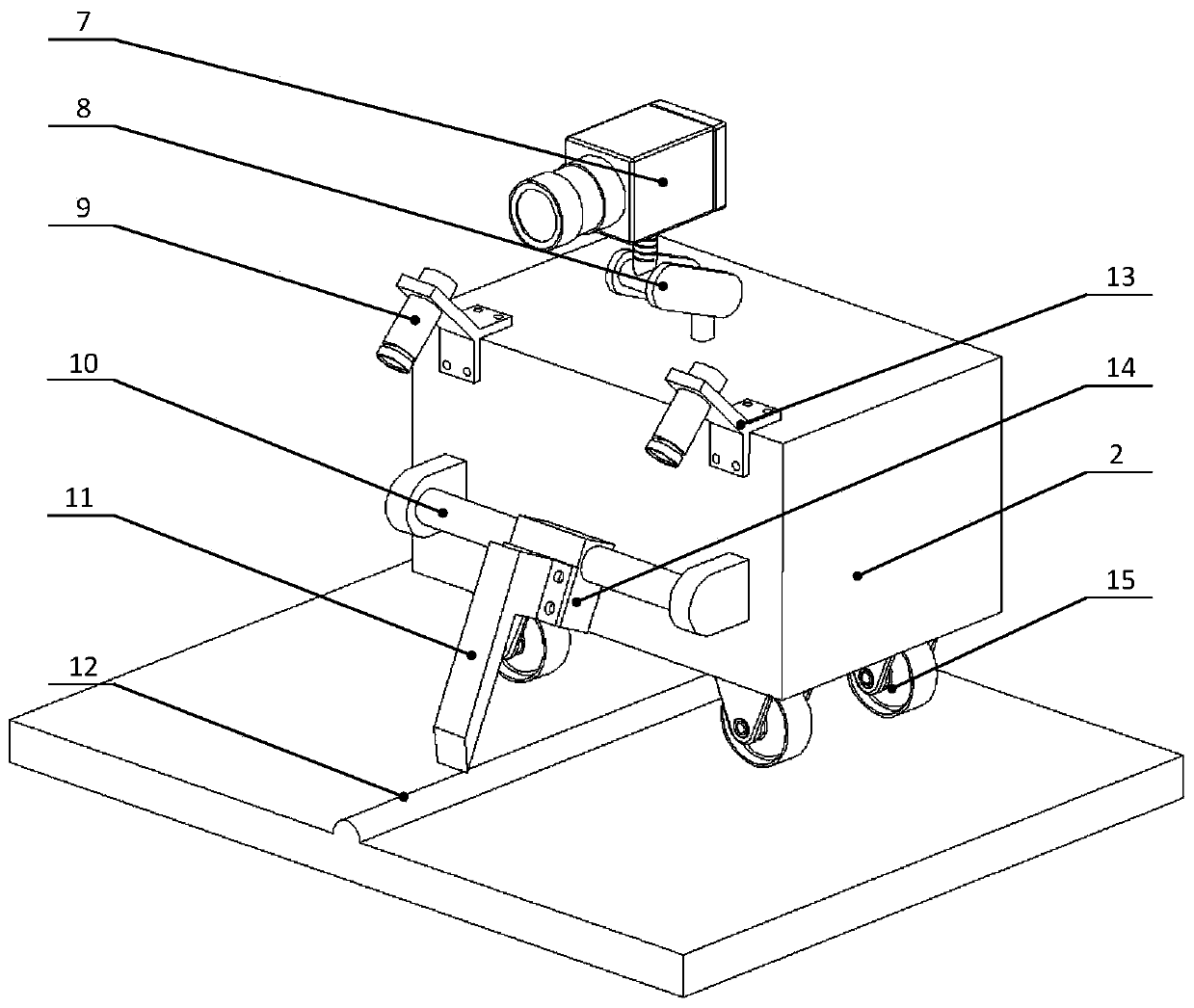

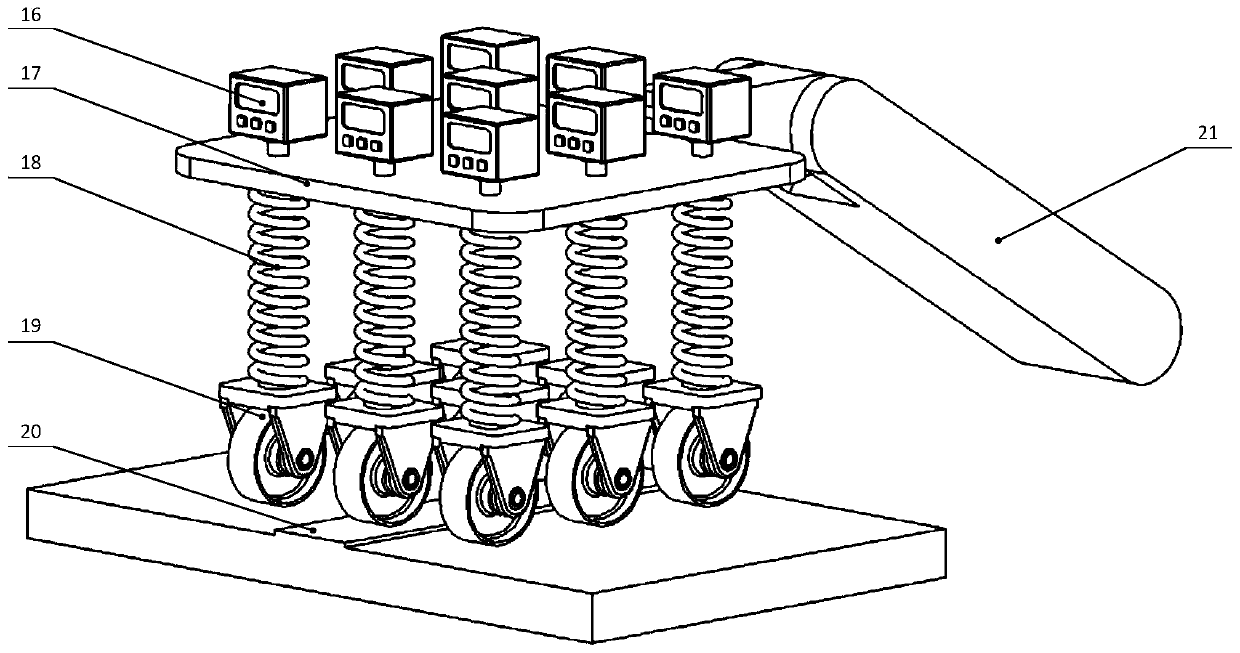

[0038] exist Figure 1 ~ Figure 3Among them, a device for removing burrs in submerged arc welded pipes, including a computer 5, a frame 3, two pairs of support rollers 4 on the left and right that are arranged on the frame 3 and are used to place the tube blank 1, and are placed on the tube blank when removing the internal burrs 1. The internal trolley 2 and the burr residual height detection device; the computer 5 is placed on the console 6 in front of the frame 3; the bottom of the trolley 2 is provided with wheels 15, and the top of the trolley 2 is equipped with a device for taking images of internal burrs to be scraped The image recognition device of the car 2 is equipped with a scraping device for scraping internal burrs on the lower part of the side body of the trolley 2, and a temperature measuring device for measuring the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com