Preparation method of low-temperature sintered high-crystallinity silver powder

A high-crystallinity, low-temperature sintering technology, applied in the field of chemistry, can solve the problems of low crystallinity and high sintering temperature of silver powder, and achieve the effects of low production cost, good stability and simple reaction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

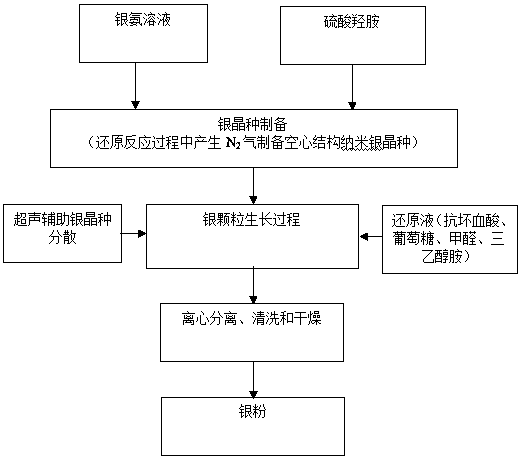

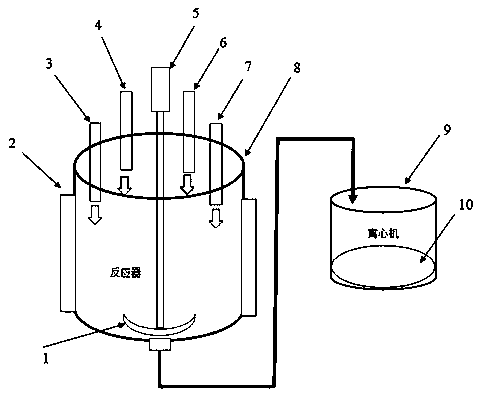

[0020] Such as figure 1 Shown, the present invention provides a kind of preparation method of low-temperature sintering high crystallinity silver powder, comprises a process that utilizes chemical reduction method to obtain metallic silver particles from silver ammonia solution in reactor 8, utilizes chemical reduction method in described In the process of obtaining metal silver particles from the silver ammonia solution, the silver ammonia solution is used as an oxidizing agent, the silver ammonia solution is added in the reactor 8, and the hydroxylamine sulfate is used as a reducing agent, and the hydroxylamine sulfate is added in the reactor 8 in a jet mode, so that Hydroxylamine sulfate and silver ammonia solution are fully mixed in reactor 8, utilize the N produced in the reaction process 2 Gas, micro-nano bubbles are formed in the solution environment, and silver is deposited on the micro-nano bubbles to form nano-silver seeds with a hollow structure; then use one or mor...

Embodiment 2

[0027] Such as figure 2 As shown, the invention provides a kind of preparation method of low temperature sintering high crystallinity silver powder, comprises the steps:

[0028] 1) Weigh 5Kg of silver nitrate solid and place it in the reactor 8, add 95L of deionized water through the deionized water feed port 6, and then turn on the stirring motor 5 to drive the stirring paddle 1 to stir for dissolution, and the stirring speed is 60 rpm. After the dissolution is completed, add ammonia water with a mass percentage concentration of 25% through the ammonia water feed port 3 to adjust until the silver nitrate precipitates and then dissolves completely. At this time, the pH of the system is 9-10. Finally, weigh 650 g of solid dispersant PVP (polyvinylpyrrolidone) and place it in reactor 8, stir and dissolve to form silver ammonia solution oxidation solution, and heat and keep it at 37°C;

[0029] 2) inject 137 milliliters of the hydroxylamine sulfate aqueous solution that contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com