Atomic force microscope and test method of sample surface property

An atomic force microscope and sample technology, used in scanning probe microscopy, measuring devices, instruments, etc., can solve problems such as difficulty in up and down vibration, low vibration frequency, inability to achieve high-speed testing, etc. The effect of shortening the test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of an atomic force microscope and a test method for sample surface properties according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments , structure, feature and effect thereof, detailed description is as follows.

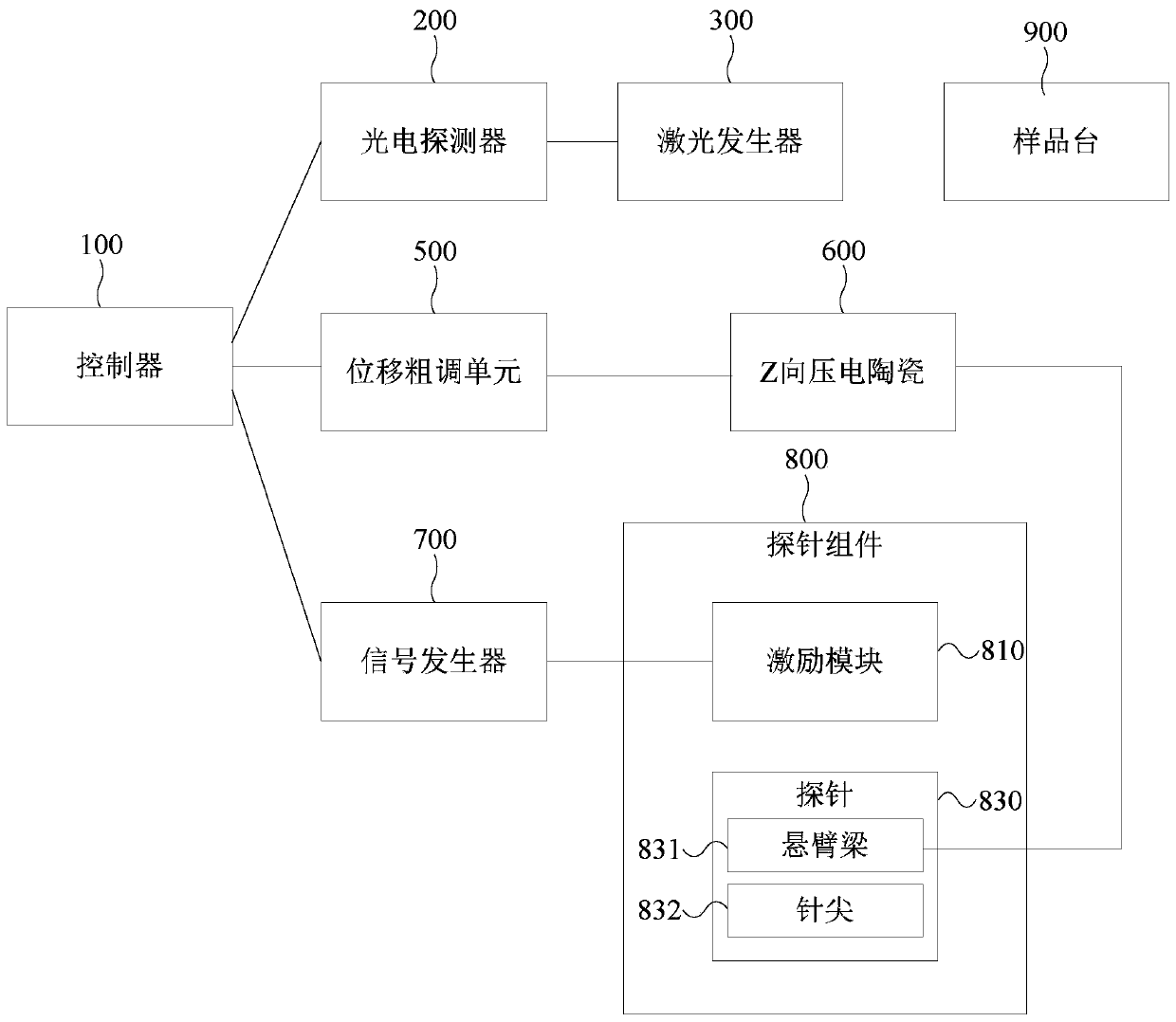

[0043] An embodiment of the present invention provides an atomic force microscope, which includes:

[0044] A signal generator for generating and outputting an excitation signal and a synchronization signal;

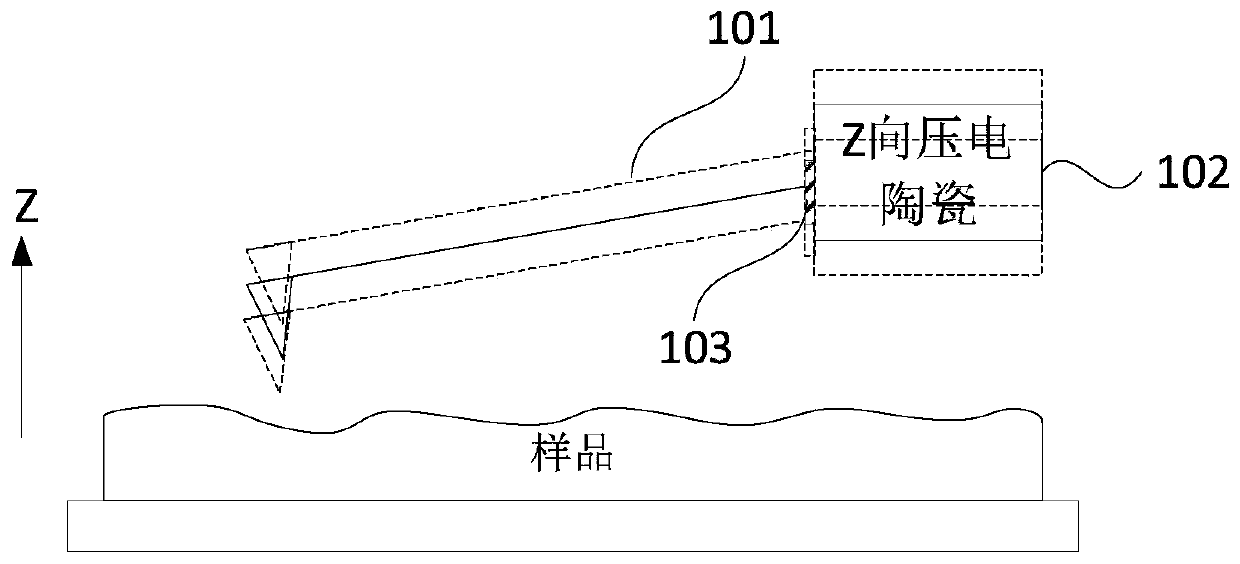

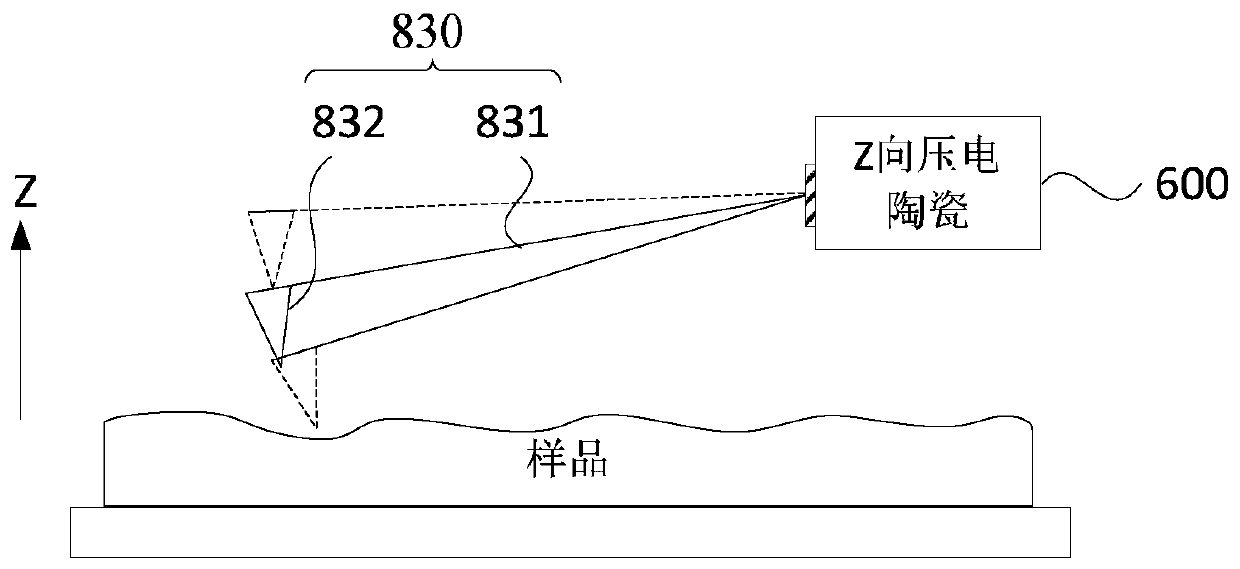

[0045] Probe assembly, the probe assembly includes a probe and an excitation module, the probe includes a cantilever beam and a needle tip located at the first end of the cantilever beam, the excitation module is connected to the signal generator for receiving the excitation signal, and drive the probe to deflect in a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com