VOC water removal collecting trap

A technology of traps and traps, which is applied in the field of environmental inspection and monitoring systems, can solve problems such as inconvenient installation and replacement, influence on monitoring results, and clean water inflow, so as to avoid and reduce material adsorption problems, The effect of increasing the heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

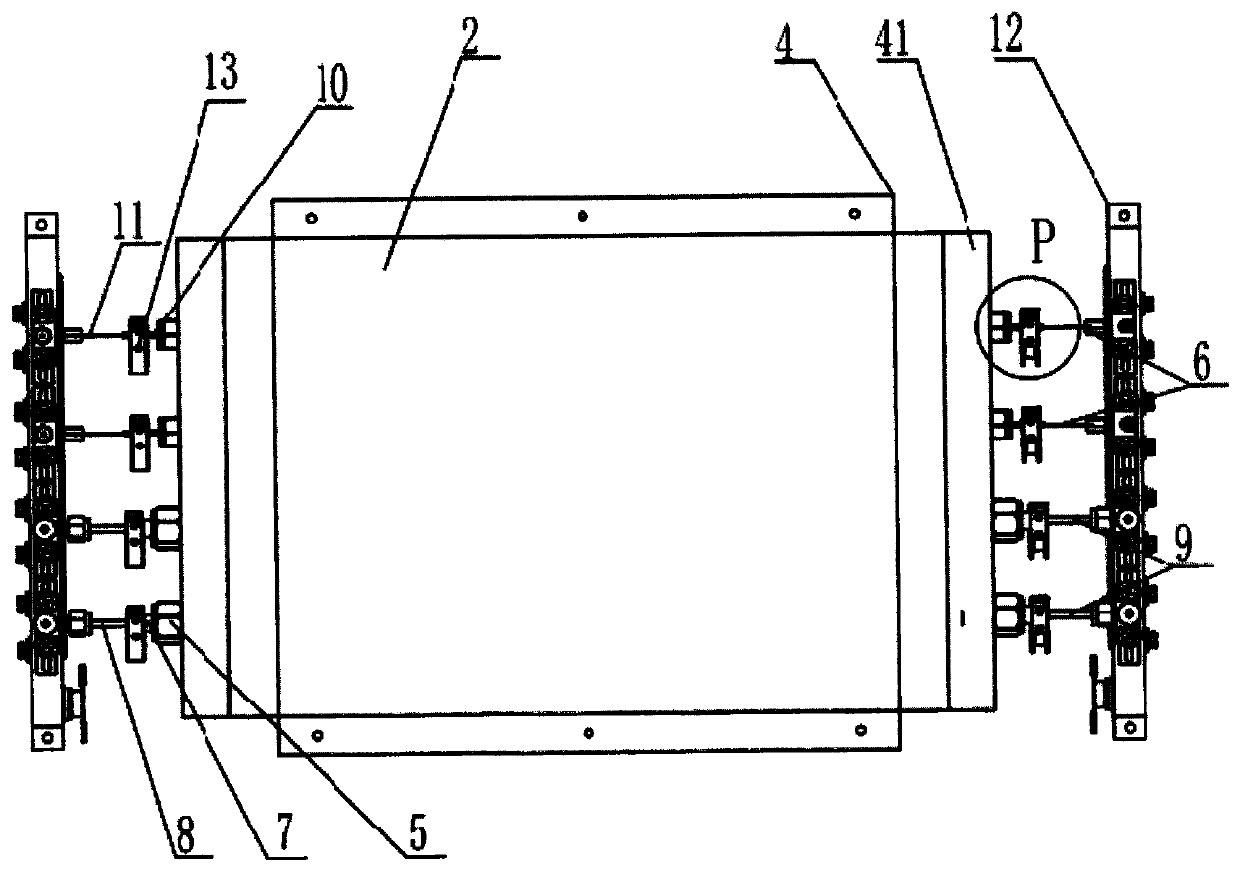

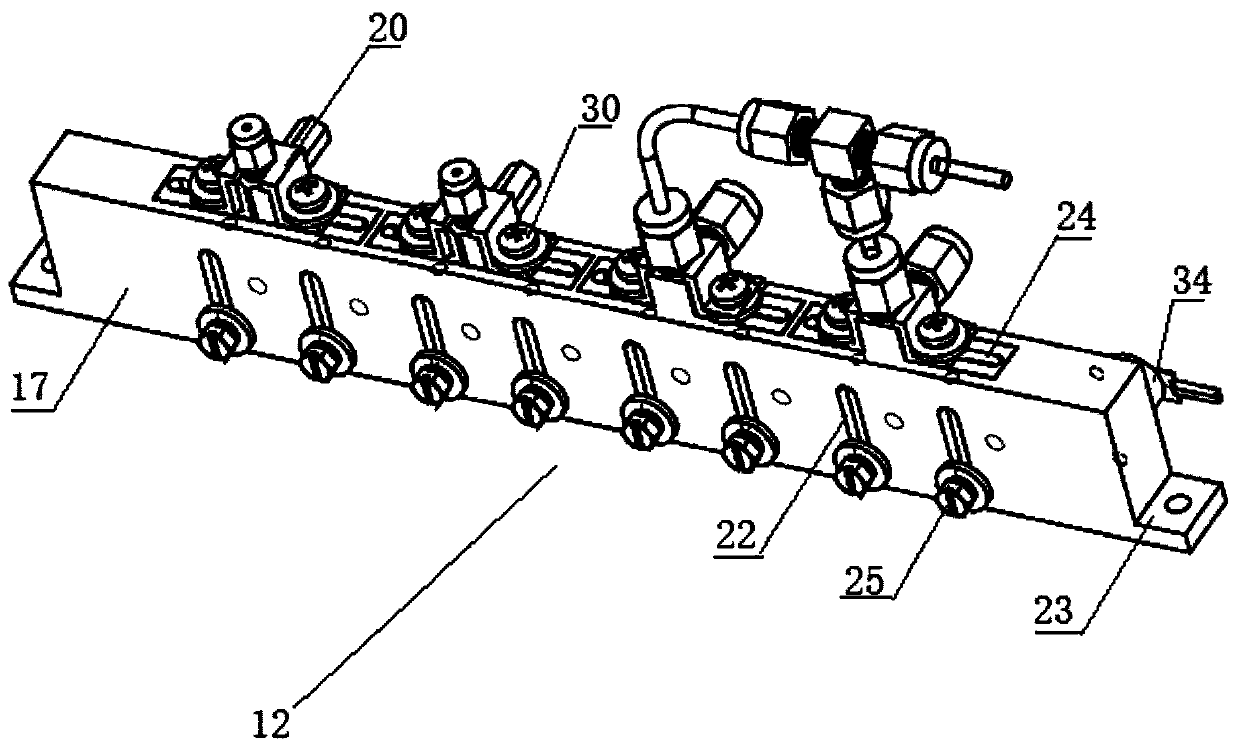

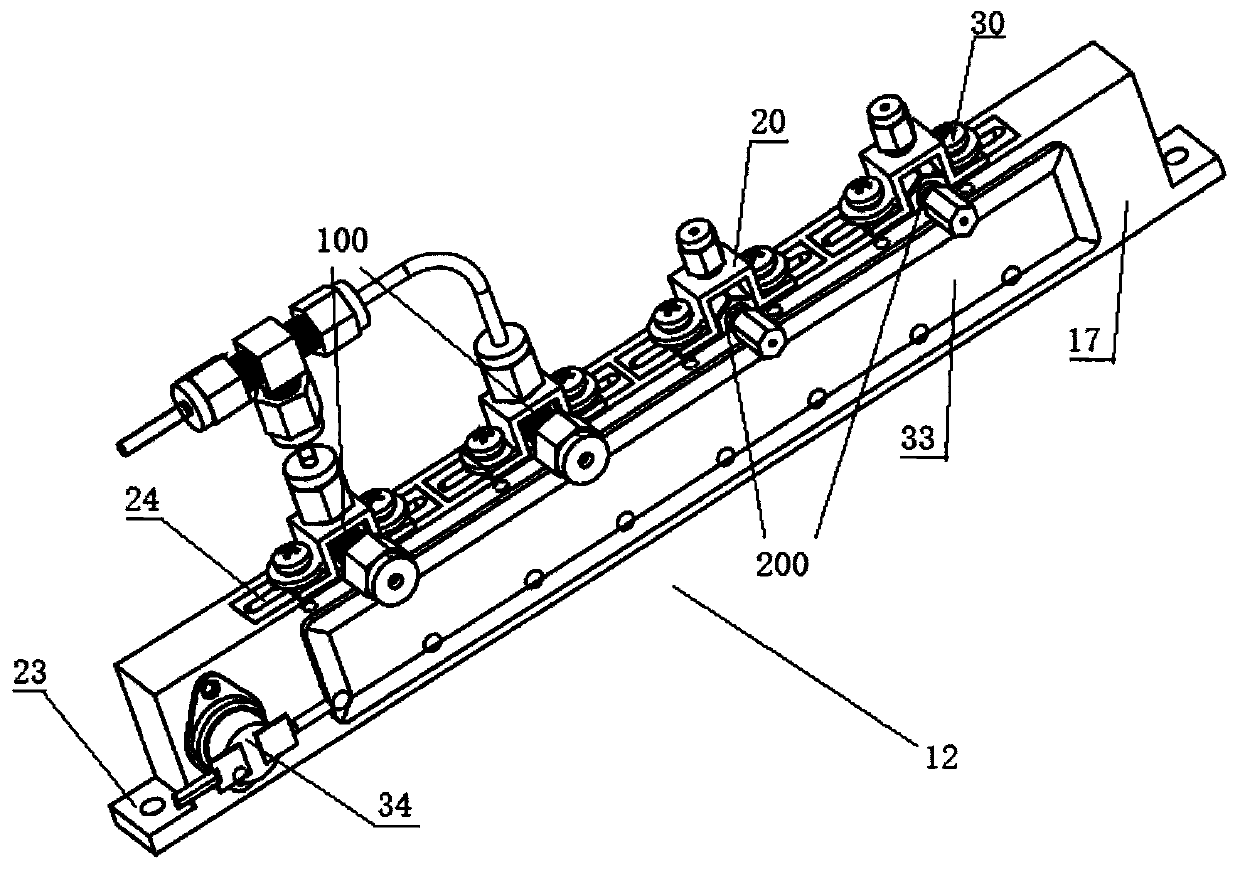

[0070] Most of the existing atmospheric VOC detection systems are structurally divided into three parts: refrigeration system, heating system, and control system. The commonly used device is the electric refrigeration water removal trap, which has the following structural defects: first, the chromatographic column and the silanized water removal pipe surround the inside of the cylindrical refrigeration module, and the trapping and analysis are carried out inside the refrigeration module. And the water removal pipe surrounds the cold module. Once a problem occurs, it is inconvenient to install and replace, and even needs to be returned to the factory for repair. Secondly, the silanized water removal pipe is expensive and needs to be replaced regularly due to technical defects. The spiral structure is difficult when water enters the water removal pipe. Thoroughly remove the incoming water; and the temperature measuring wire goes deep into the water removal pipe. When the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com