Method for detecting surface defects of anti-inflammatory drug granules

A defect detection and drug particle technology, which is applied in optical testing defects/defects, measuring devices, image data processing, etc., can solve the problems of lack of particles, the influence of inspection accuracy fatigue and experience, foreign matter on the surface of drug particles, etc., to achieve simple detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0032] The first step is to obtain the image of the drug particles in the drug board, that is, to collect the image of the drug particles through a color camera;

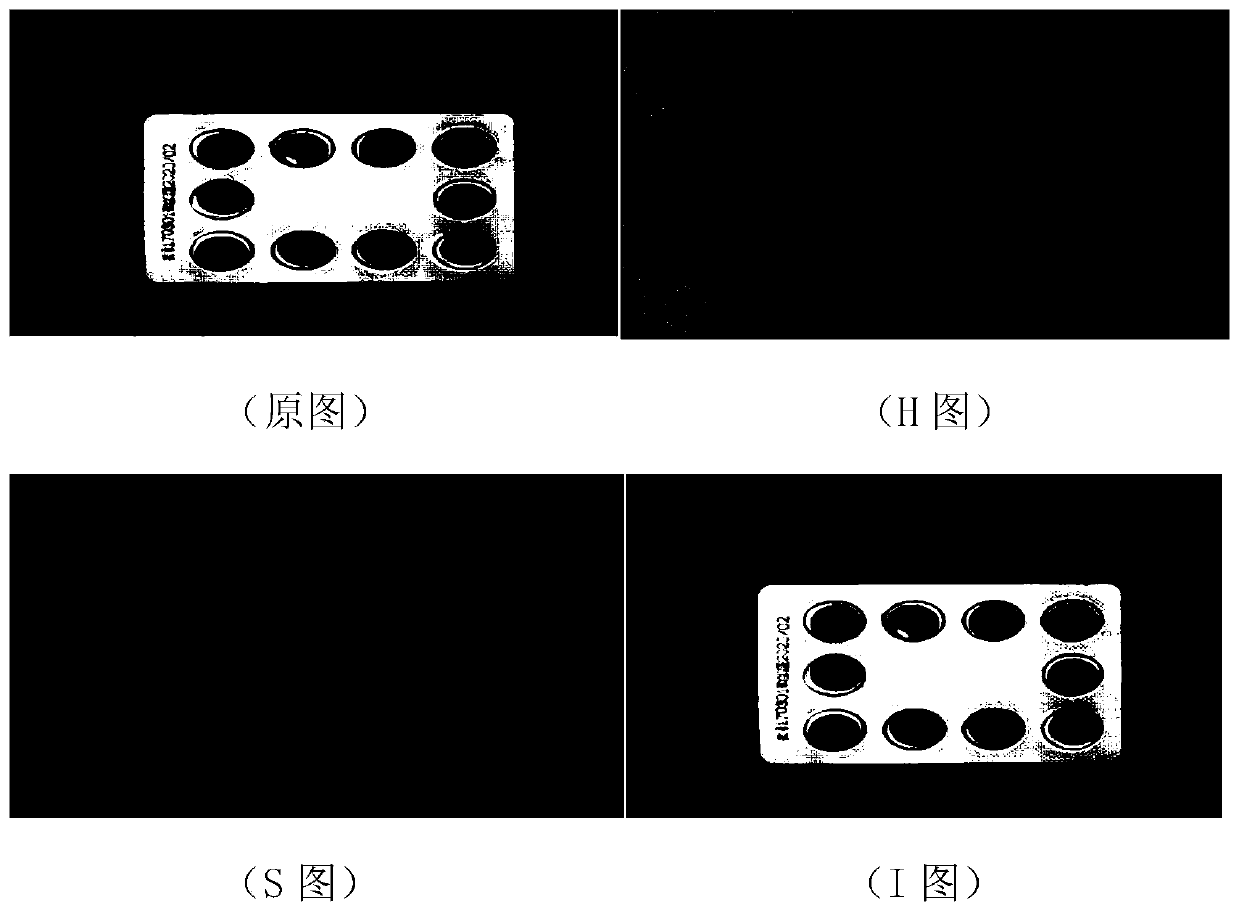

[0033] The second step is to convert the image, that is, to convert the image of the drug particles collected in the first step into H 1 S 1 I 1 image;

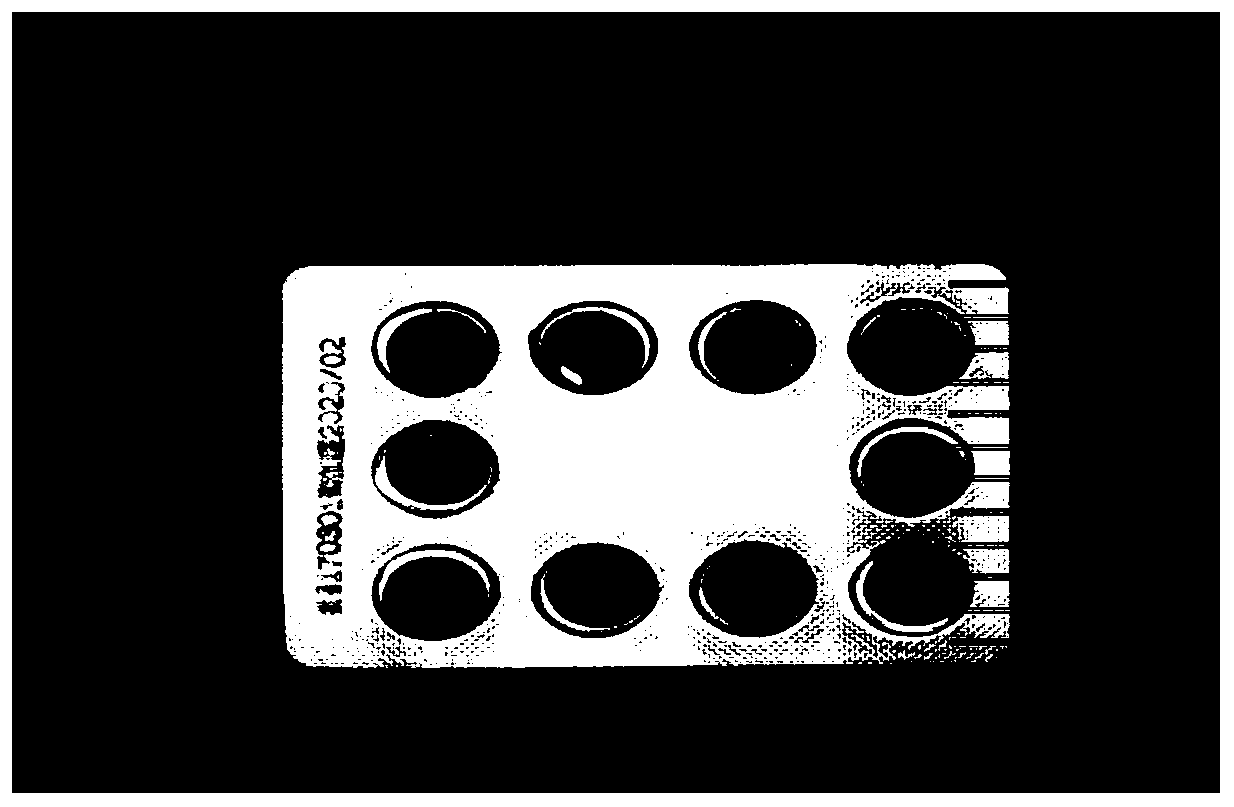

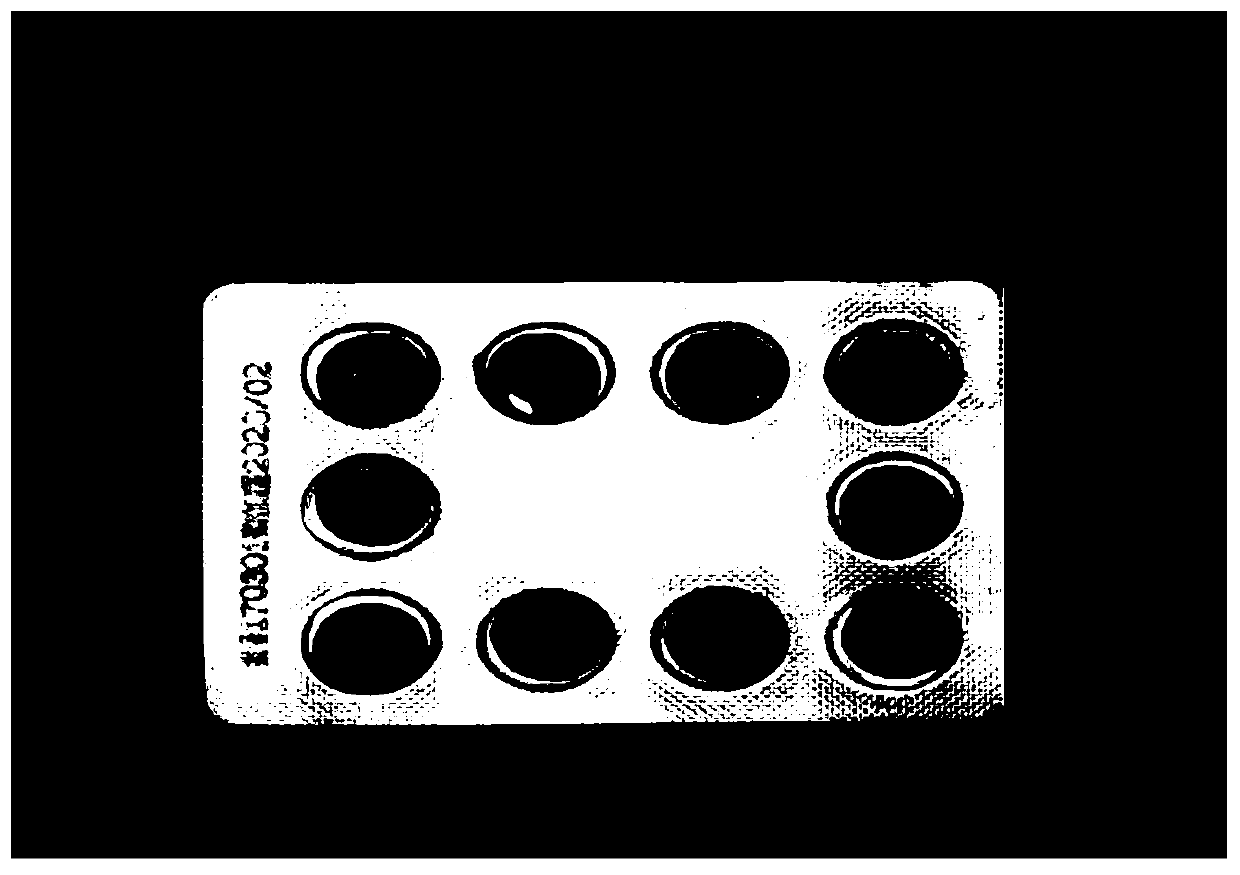

[0034] The third step is image correction, that is, the I converted into the second step 1 In the image, set n=100 rectangular detection areas with height H=200 and width W=10 on the right edge of the medicine board, and obtain the point coordinate set (X(n), Y (n)), the point coordinate set is fitted into the right edge line by Hough transform, and the center point coordinates (2030, 1184) of the right edge of the medicine plate are obtained, according to the angle (-89°) of the right edge line and Center point coordinates (2030, 1184), correct the image with reference to the template position (angle (-85°) and center point coordinates (2010, 1181)), and gener...

specific Embodiment 2

[0039] The first step is to obtain the image of the drug particles in the drug board, that is, to collect the image of the drug particles through a color camera;

[0040] The second step is to convert the image, that is, to convert the image of the drug particles collected in the first step into H 1 S 1 I 1 image;

[0041] The third step is image correction, that is, the I converted into the second step 1In the image, set n=100 rectangular detection areas with height H=200 and width W=10 on the right edge of the medicine board, and obtain the point coordinate set (X(n), Y (n)), the point coordinate set is fitted into the right edge line by Hough transform, and the center point coordinates (2028, 1186) of the right edge of the medicine plate are obtained, according to the angle (-88°) of the right edge line and Center point coordinates (2028, 1186), correct the image with reference to the template position (angle (-85°) and center point coordinates (2010, 1181)), and genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com