Leak detection method for a refrigeration system

A refrigeration system and leak detection technology, which is applied in the direction of measuring the acceleration and deceleration rate of the fluid and using the liquid/vacuum degree for liquid tightness measurement, etc., which can solve problems such as failure to detect leakage, drying, and product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will now be further explained.

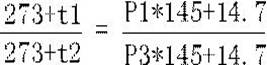

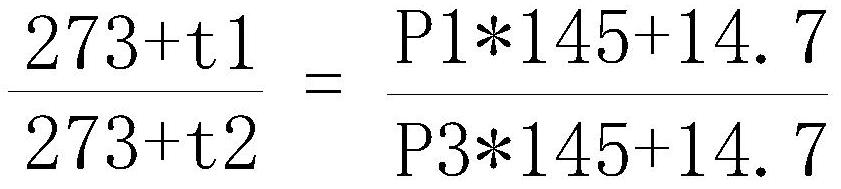

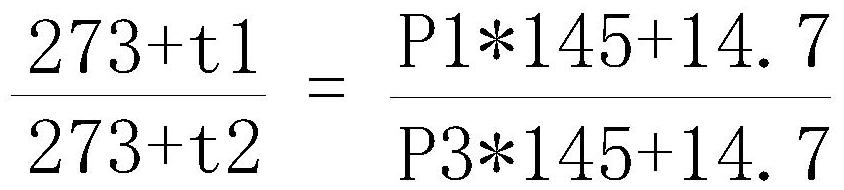

[0056] A leak detection method for a refrigeration system includes the following steps:

[0057] S101, vacuumize the refrigeration system once;

[0058] S102. Vacuum pressure keeping. After the refrigeration system is evacuated, vacuum pressure is maintained. The pressure holding time is 1 to 5 minutes. If the pressure after vacuum pressure is not less than the first vacuum pressure, enter S103, if the pressure after vacuum pressure is less than In the first vacuum pressure, a vacuum pressure alarm is performed;

[0059] S103. Fill the test gas with nitrogen and hydrogen mixed gas into the refrigeration system, and stop charging when the test pressure is reached;

[0060] S104. Detect the pressure after charging, and detect the pressure of the refrigeration system after the nitrogen-hydrogen mixed gas is charged. If the pressure is not less than the detected pressure, a sniffer leak detection is performed, and if the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com