Double-hardness rubber substrate for shoes for physical fitness tests and preparation method thereof

A dual-hardness, rubber material technology, used in shoe soles, footwear, applications, etc., can solve problems such as unsatisfactory physical properties, deflection and deformation of shoes, and uneven wear and tear, achieving stable physical properties, light soles, Appropriate effect of hardness difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The double-hardness physical fitness test shoe rubber base material of the present embodiment comprises a high-hardness rubber material and a low-hardness rubber material, the hardness of the low-hardness rubber material is 30A, and the hardness of the high-hardness rubber material is 50A;

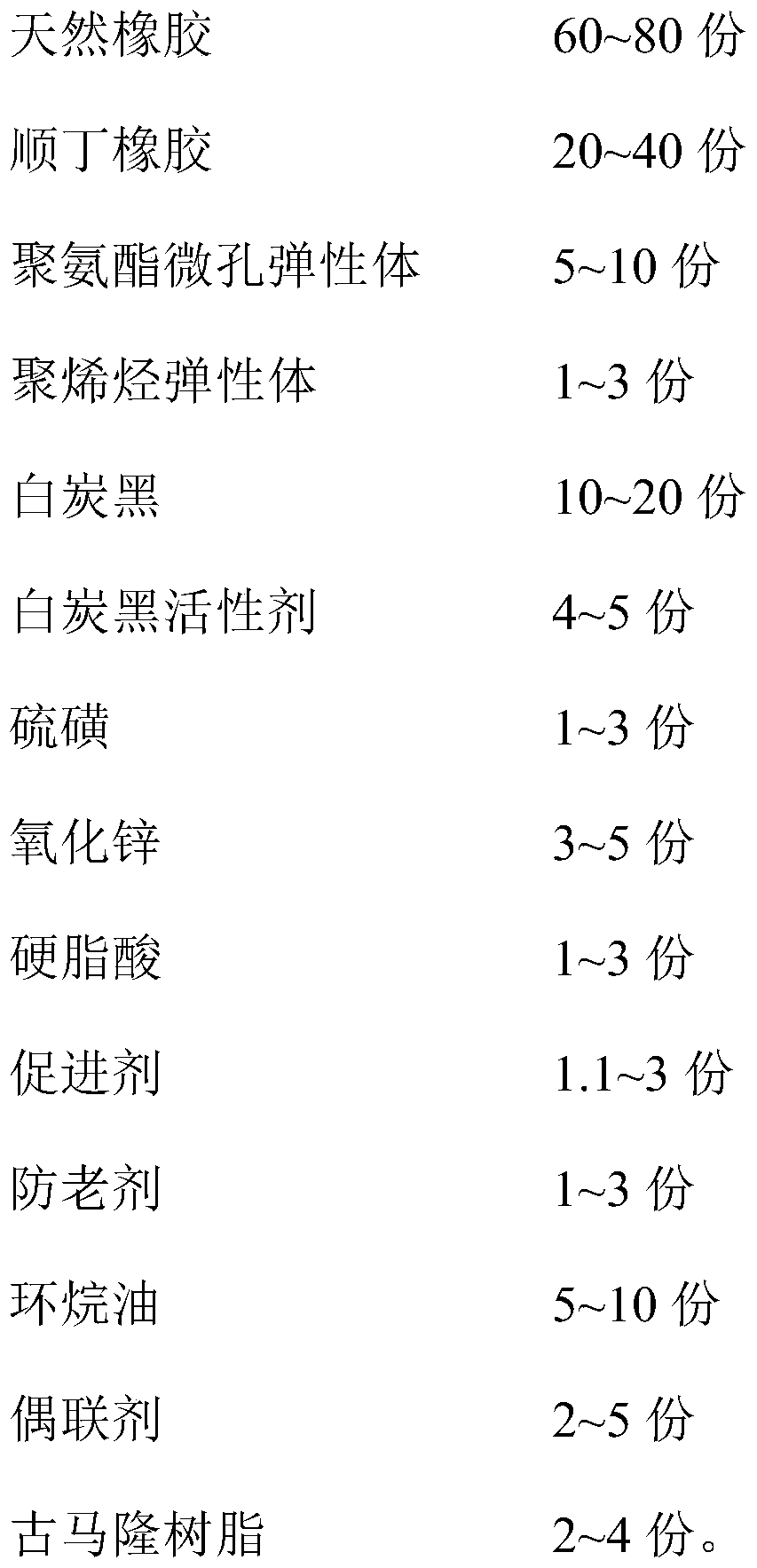

[0069] In parts by weight, the low-hardness rubber material comprises the following components:

[0070]

[0071]

[0072] Wherein, in the low-hardness rubber material, the hardness of the polyurethane microcellular elastomer is 40A, and the molding density of the polyurethane microcellular elastomer is 0.4g / m 3 ; The accelerator is composed of 1 part of accelerator DM and 1 part of accelerator TMTM-80; the coupling agent is composed of 2 parts of A189 silane coupling agent and 1 part of SI-69 silane coupling agent; the anti-aging agent is BHT anti-aging agent, MB The mixture of anti-aging agent, petrolatum and paraffin, the weight ratio is 0.5:0.3:1:0.5.

[0073] The prepara...

Embodiment 2

[0083] The dual-hardness physical fitness test shoe rubber base material of the present embodiment comprises a high-hardness rubber material and a low-hardness rubber material, the hardness of the low-hardness rubber material is 40A, and the hardness of the high-hardness rubber material is 50A;

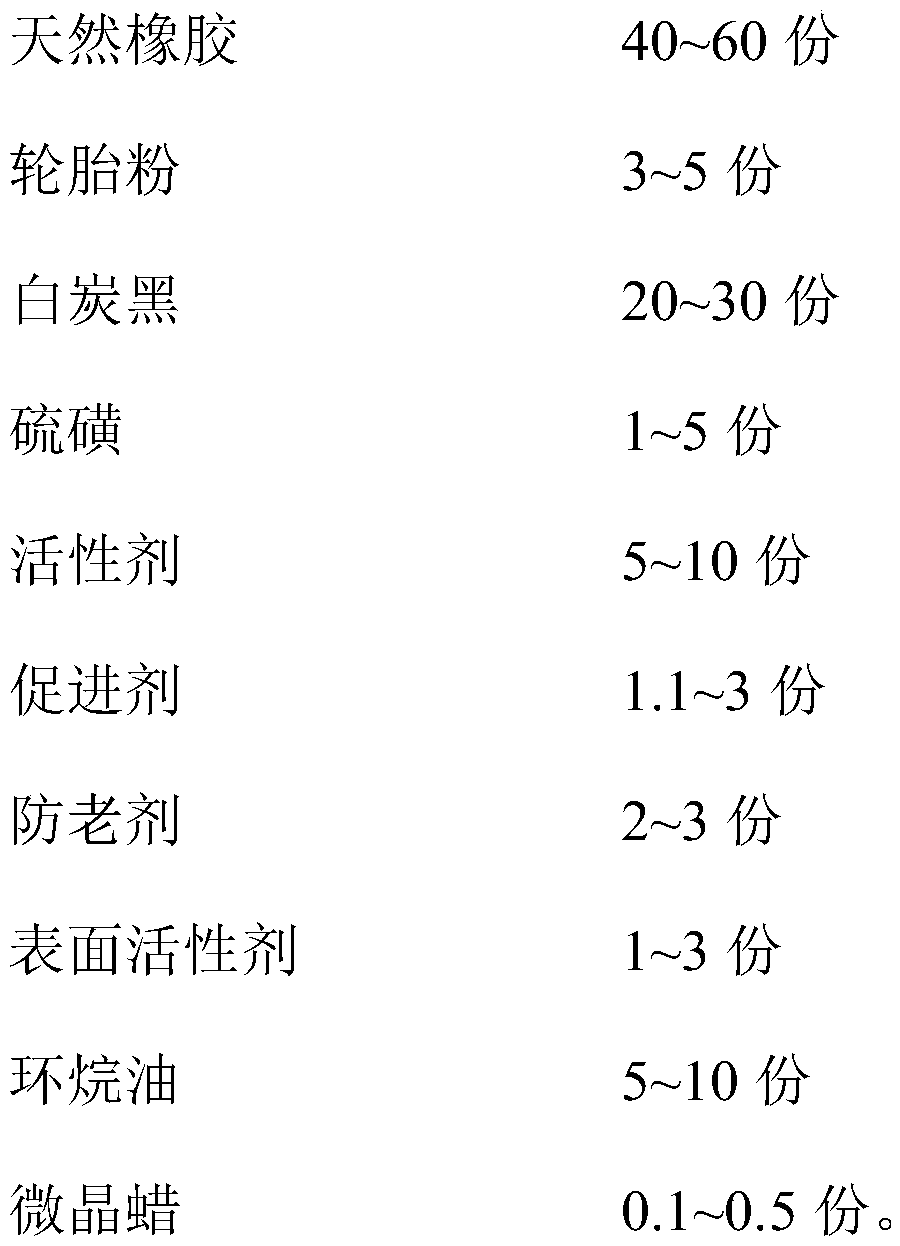

[0084] In parts by weight, the low-hardness rubber material comprises the following components:

[0085]

[0086]

[0087] Wherein, in the low-hardness rubber material, the hardness of the polyurethane microcellular elastomer is 45A, and the molding density of the polyurethane microcellular elastomer is 0.5g / m 3 ; The accelerator is composed of 1 part of accelerator DM and 1 part of accelerator TMTM-80; the coupling agent is composed of 2 parts of A189 silane coupling agent and 1 part of SI-69 silane coupling agent; the anti-aging agent is BHT anti-aging agent, MB The mixture of anti-aging agent, petrolatum and paraffin, the weight ratio is 1:0.3:1:0.5.

[0088] The preparation...

Embodiment 3

[0098] The double-hardness physical fitness test shoe rubber base material of the present embodiment comprises a high-hardness rubber material and a low-hardness rubber material, the hardness of the low-hardness rubber material is 35A, and the hardness of the high-hardness rubber material is 55A;

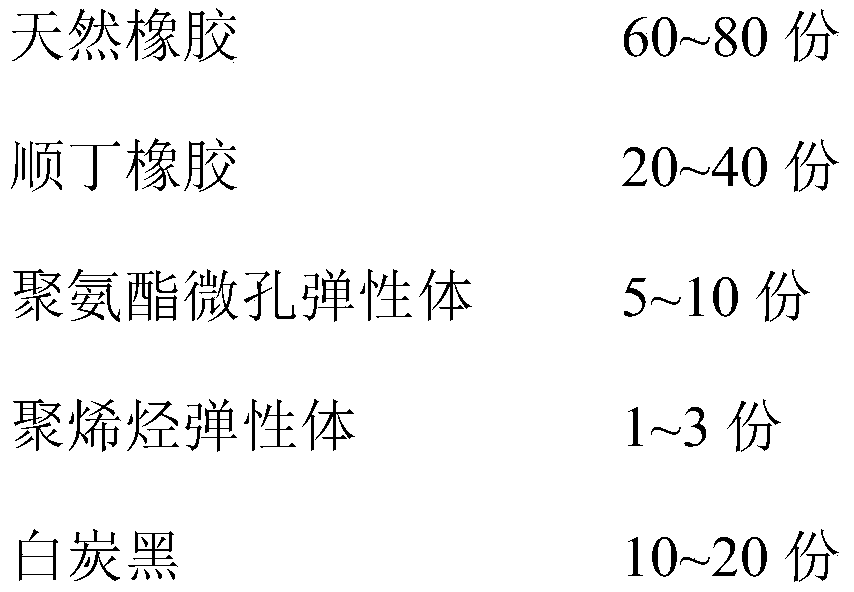

[0099] In parts by weight, the low-hardness rubber material comprises the following components:

[0100]

[0101]

[0102] Wherein, in the low-hardness rubber material, the hardness of the polyurethane microcellular elastomer is 46A, and the molding density of the polyurethane microcellular elastomer is 0.6g / m 3 The accelerator is composed of 1 part of accelerator DM and 1.4 parts of accelerator TMTM-80; the coupling agent is composed of 1.5 parts of A189 silane coupling agent and 2 parts of SI-69 silane coupling agent; the anti-aging agent is BHT anti-aging agent, MB The mixture of anti-aging agent, petrolatum and paraffin, the weight ratio is 0.8:0.2:1:0.5.

[0103] The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com