Full-automatic pneumatic grinding machine and method thereof

A pneumatic grinding machine, fully automatic technology, applied in the direction of grinding machine parts, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of small enterprises difficult to bear, large processing errors, insufficient tool pre-pressure, etc. Achieve a wide range of use and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

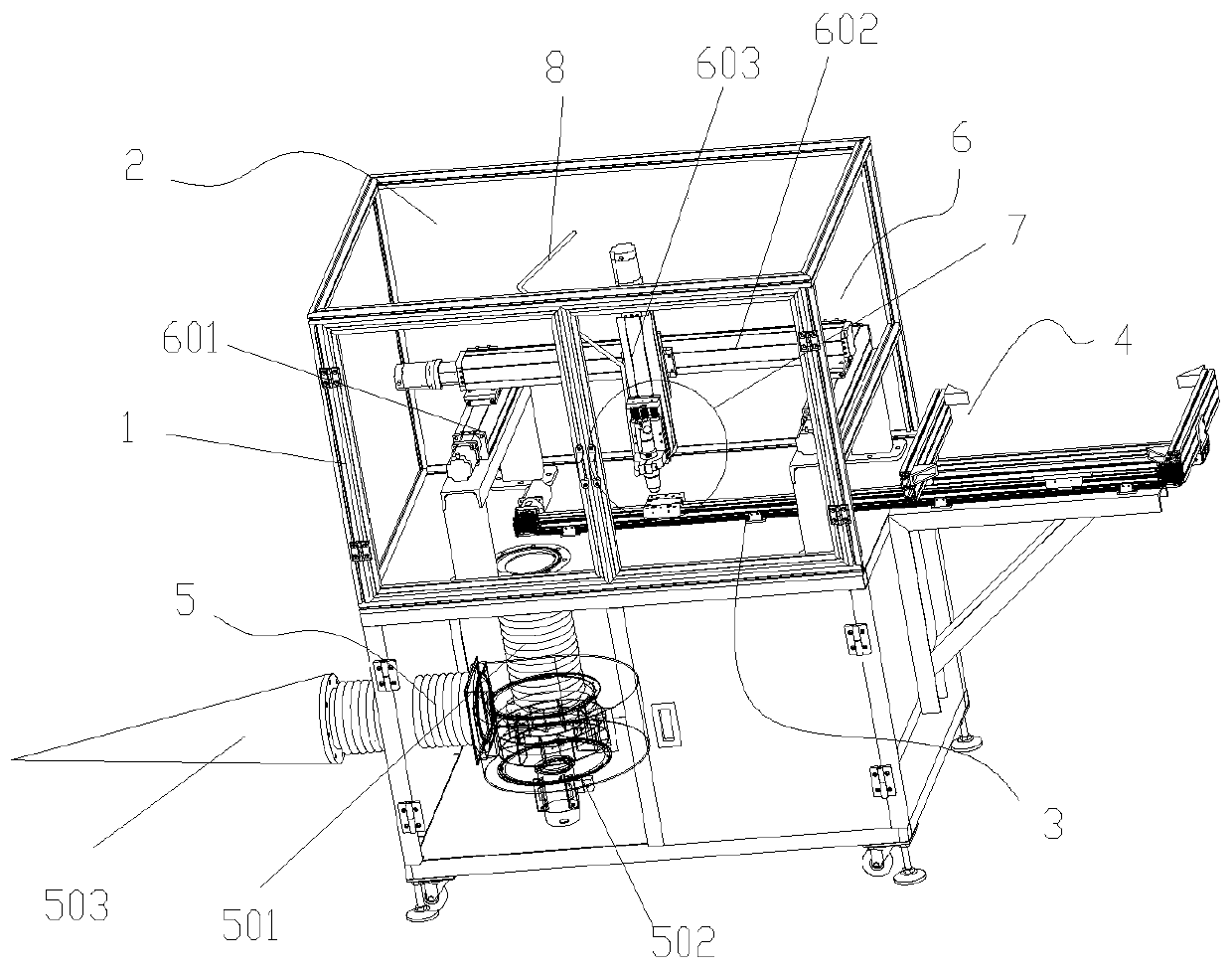

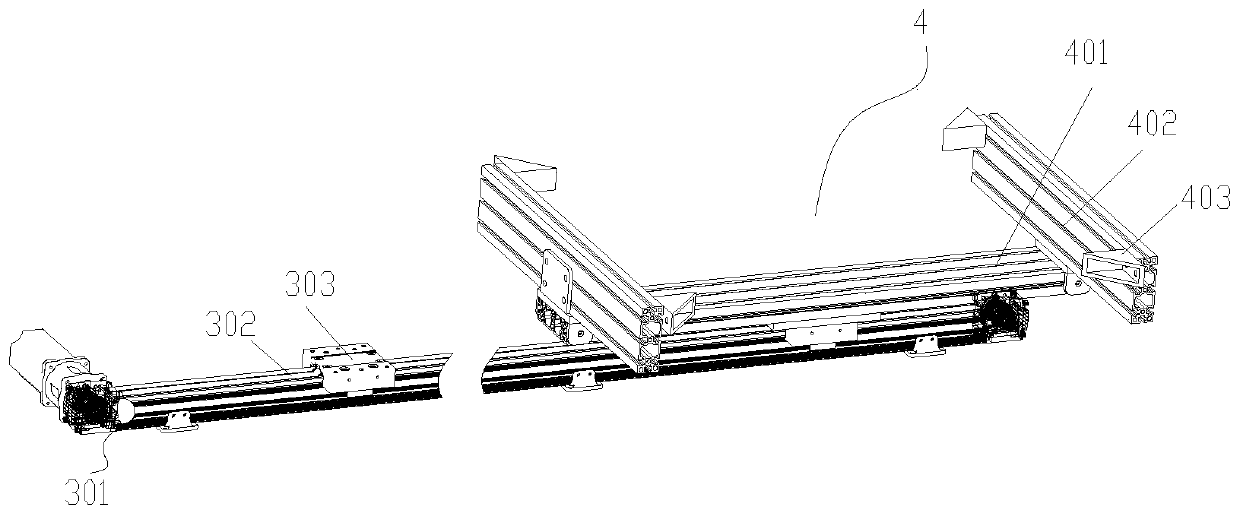

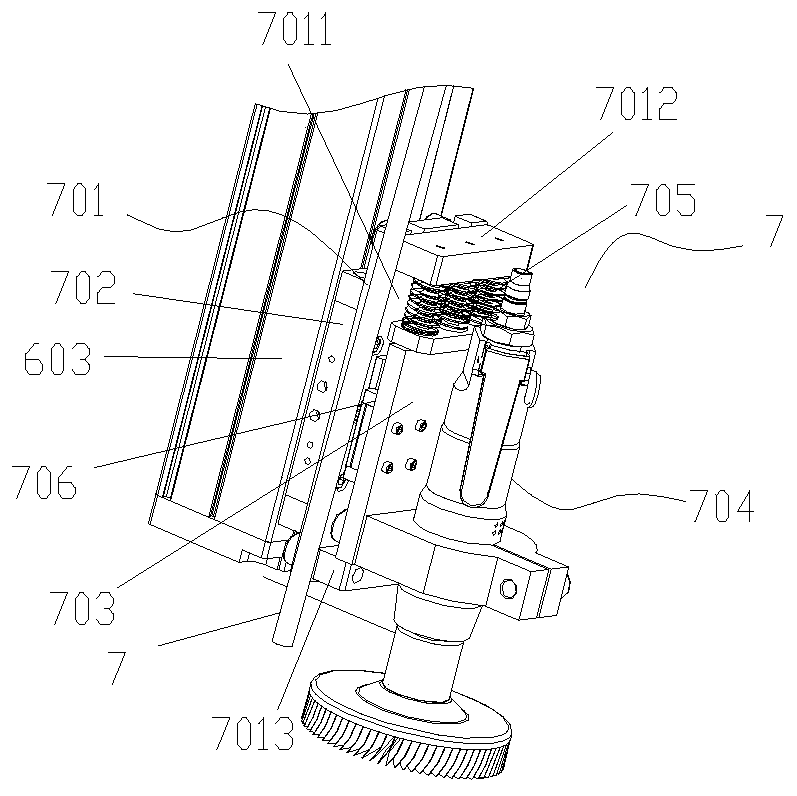

[0026] As shown in the figure: a fully automatic pneumatic grinding machine according to the present invention includes a frame 1 and a dust collection chamber 2, a grinding device is provided in the dust collection chamber 2, and a grinding device is provided at the lower end of the grinding device for making materials The material conveying device 3 of the input and output dust collection chamber 2 is provided with an adjustable clamp 4 for clamping materials; the dust collection chamber 2 is also provided with a blower for blowing off workpiece grinding Gas device 8, the bottom surface of the dust collection chamber 2 is provided with a dust outlet, and the dust outlet is connected with a dust removal device 5. The grinding device is a multi-axis grinding mechanism 6. More preferably, the multi-axis grinding mechanism 6 includes a horizontal motion guide rail I 601, a horizontal motion guide rail II 602, a vertical motion guide rail 603 and a tool assembly arranged on the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com