Preparation method and application of carbon nanotube foam-loaded core-shell Ni-Co LDH@Ni-Mn LDH

A carbon nanotube and core-shell technology, applied in the field of electrochemistry, can solve the problems of low device energy density, low specific capacitance, and limited application fields of electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) ultrasonically disperse 200 mg of single-walled carbon nanotubes in a mixture of concentrated sulfuric acid (98.0% by mass fraction) and concentrated nitric acid (68.0% by mass) with a volume ratio of 3:1, reflux at 70°C for 2h, and add distilled water Dilute and stir, filter with suction and wash with distilled water until neutral, and finally dilute with distilled water to obtain a concentration of 1 mg mL -1 acidified single-walled carbon nanotube dispersion.

[0035] (2) Cut the polyurethane foam into 1×1×1cm 3 cube (in the specific implementation process, the foam can be cut into the required size and shape according to the requirements), and then washed by washing powder, distilled water, and ethanol ultrasonically (ultrasonic power is 500W, and the time is 20min) and dried at 70°C for 12h Finally, immerse in the acidified single-wall carbon nanotube dispersion obtained in step (1), and squeeze with tweezers for 3-5 seconds to fully coat the carbon nanotube s...

Embodiment 2

[0041] In this embodiment, steps (1), (2), and (3) are the same as in Embodiment 1.

[0042] (4) Dissolve manganese chloride, nickel chloride, and hexamethylenetetramine in 40 mL of distilled water, and stir for 30 minutes. The concentrations of manganese chloride, nickel chloride, and hexamethylenetetramine in the solution are 0.0035 mol in turn. L -1 , 0.0055mol L -1 , 0.0375mol L -1 . Transfer the solution into a 50mL polytetrafluoroethylene reactor, immerse the NSCS in the solution, put the reactor into an oil bath at 90°C for chemical deposition for 40 minutes, and after cooling to room temperature, take out the sample and wash it with distilled water 2 to 3 times at 60°C Dry at high temperature for 12h to obtain Ni-Mn LDH / NSCS.

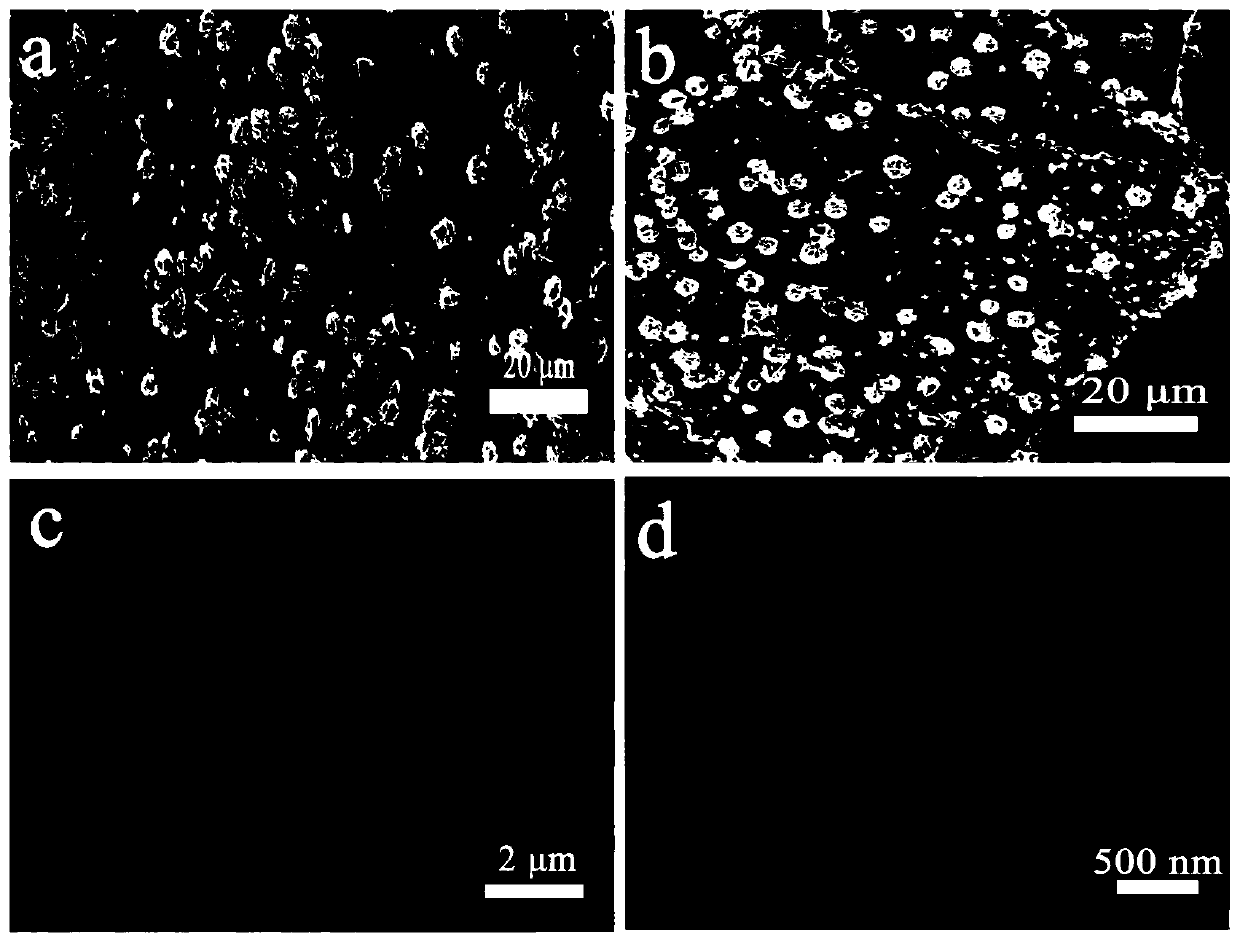

[0043] image 3 The SEM images of Ni-Mn LDH / NSCS prepared for this example, (a) and (b) are the SEM images of Ni-MnLDH / NSCS at low magnification, it can be observed that Ni-Mn LDH is spherical and The distribution is relatively sparse. Fi...

Embodiment 3

[0046] In this embodiment, steps (1), (2), and (3) are the same as in Embodiment 1.

[0047] (4) Nickel chloride, cobalt chloride, urea are dissolved in methanol aqueous solution (methanol and water volume ratio are 6:1), fully stir to form pink solution, the content of nickel chloride, cobalt chloride, urea in this pink solution The final concentration is 0.0024mol L in turn -1 , 0.0048mol L -1 , 0.1667mol L -1 , transfer the above pink solution into a 50mL polytetrafluoroethylene reactor, and immerse the NSCS obtained in step (3) into it, and conduct a hydrothermal reaction at 120°C for 6h; after cooling to room temperature, take out the sample and wash it with distilled water and absolute ethanol , the sample was placed in an oven at 60°C for 12h to obtain Ni-Co LDH / NSCS.

[0048] (5) Dissolve manganese chloride, nickel chloride, and hexamethylenetetramine in 40mL distilled water, and stir for 30min to obtain an aqueous solution; The concentration is 0.0035mol L in turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass specific capacitance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com