Throat offset type pneumatic vectoring exhaust nozzle with saw-tooth-shaped solid tabs at outlet

A vector nozzle and zigzag technology, which is applied in the field of thrust vectoring aero-engine nozzles, can solve problems such as low detectability, and achieve the effects of simple design, reduced flight resistance and large thrust vector angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

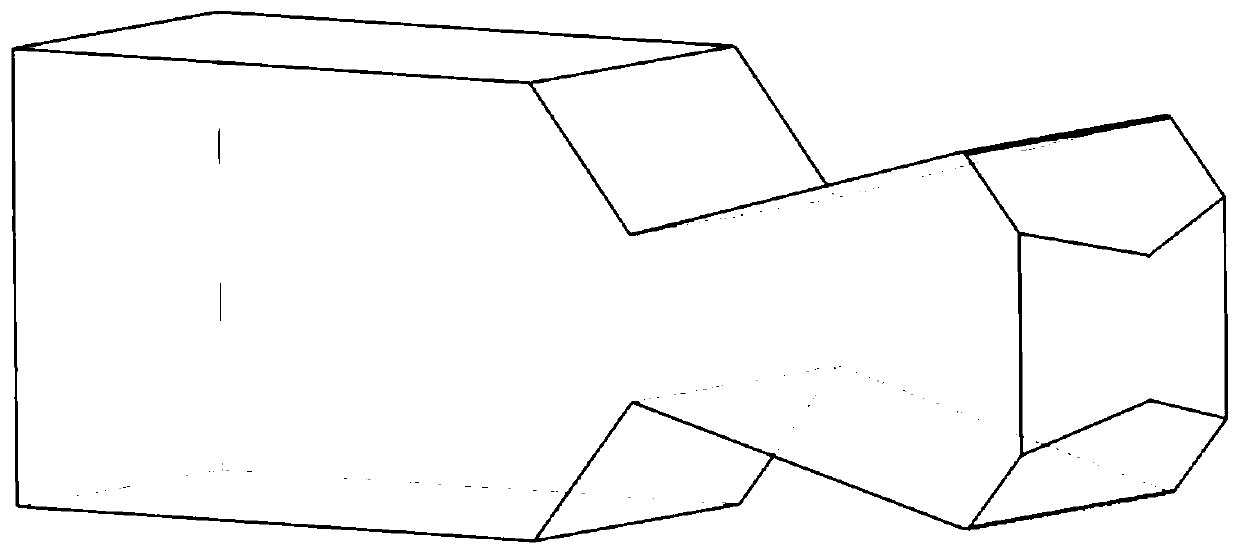

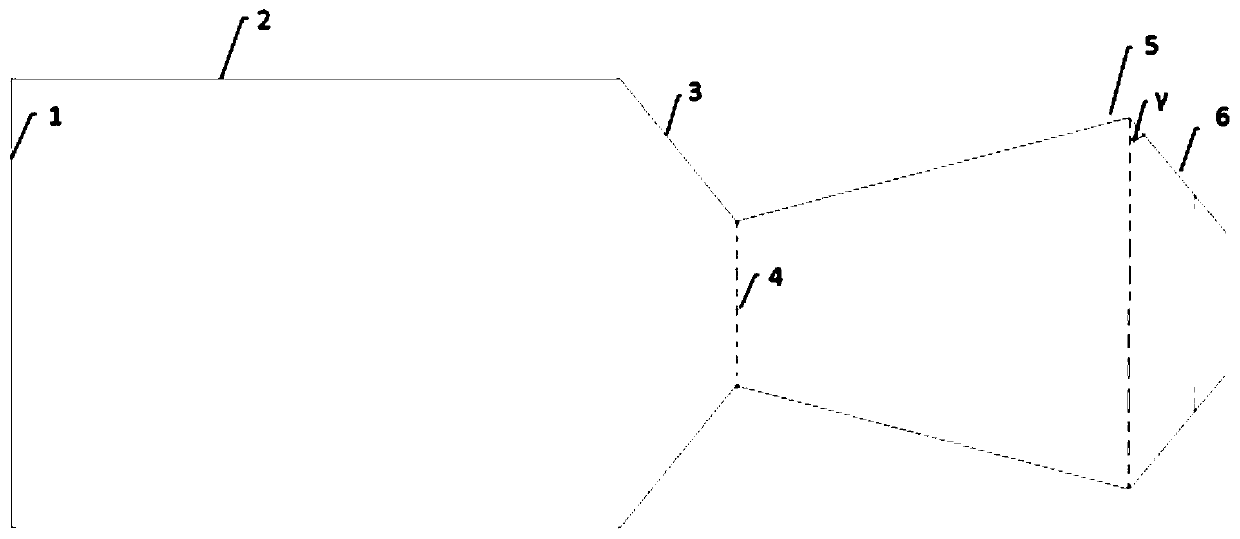

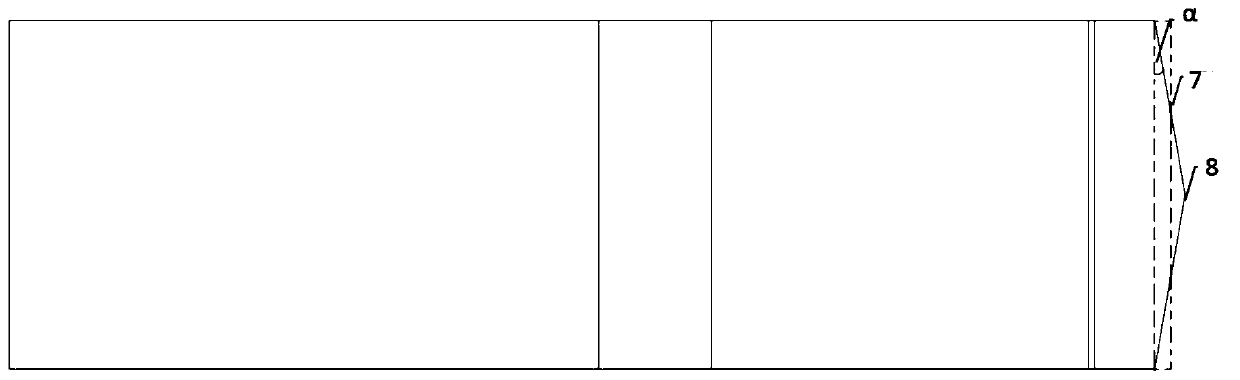

[0039] Such as Figure 1-4 Shown is a throat offset aerodynamic vectoring nozzle with saw-tooth-shaped solid tabs at the outlet, including the nozzle body, and its internal flow path sequentially includes nozzle inlet 1, equal straight section 2, and a throat front convergent Section 3, a throat 4, the expansion section 5 at the front of the second throat, a convergent section 6 at the front of the second throat, and a second throat 7. Compared with the traditional throat offset aerodynamic vector nozzle with the same size rectangular outlet, the For the nozzle of the reference configuration mentioned later, on the premise that the projected area of the outlet of the nozzle remains unchanged, the upper and lower walls downstream of the converging section 6 at the front of the second throat are provided with inwardly inclined sawtooth-shaped solid protrusions 8 .

[0040] In this embodiment, the jagged solid tab 8 is a single isosceles triangle, and the length of the base of...

Embodiment 2

[0044] Image 6 It shows the three-dimensional geometric configuration of adding baffles on both sides of the outlet of the present invention. Compared with the original configuration, this configuration can pass through the baffles on both sides to reduce the flow of airflow to both sides and cause losses, and further improve the efficiency of the nozzle. aerodynamic performance.

[0045] Side baffles can be installed symmetrically on both sides of the side wall surface downstream of the front convergent section of the second throat of the nozzle. While ensuring that the detectability is basically unchanged, the thrust performance of the nozzle is further greatly improved, and the vector of the nozzle is slightly increased. performance. The shortest side baffle is flush with the top of the solid protruding piece, that is, the length of the side baffle is not shorter than the projection of the height of the isosceles triangle of the solid protruding piece on the horizontal pl...

Embodiment 3

[0048] Figure 7 It shows a configuration of the present invention with multiple saw-tooth-shaped solid tabs. The figure shows double-saw-tooth solid tabs, and the number of tabs can be further increased to improve the aerodynamic performance of the nozzle. At this time, the isosceles triangular jagged solid protrusion is still coplanar with the front convergent section of the second throat of the nozzle, and the plane where the median line of the isosceles triangle is consistent with the reference line throat offset type aerodynamic vector nozzle. If there is only one sawtooth protruding piece, the length of the base of the isosceles triangle is consistent with the width of the wall of the nozzle; unanimous.

[0049] In the case of the same outlet projected area, the aerodynamic performance of the nozzle with multi-serrated solid tabs with a sawtooth angle of α is closer to the benchmark configuration throat-offset aerodynamic vector nozzle with no solid tabs at the outlet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com