Clothing polishing machine

A grinding machine and grinding mechanism technology, applied in textiles and papermaking, fabric surface trimming, thorn patterns, etc., can solve the problems of high production cost, slow processing efficiency, non-uniformity, etc., and achieve the effect of high-quality grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

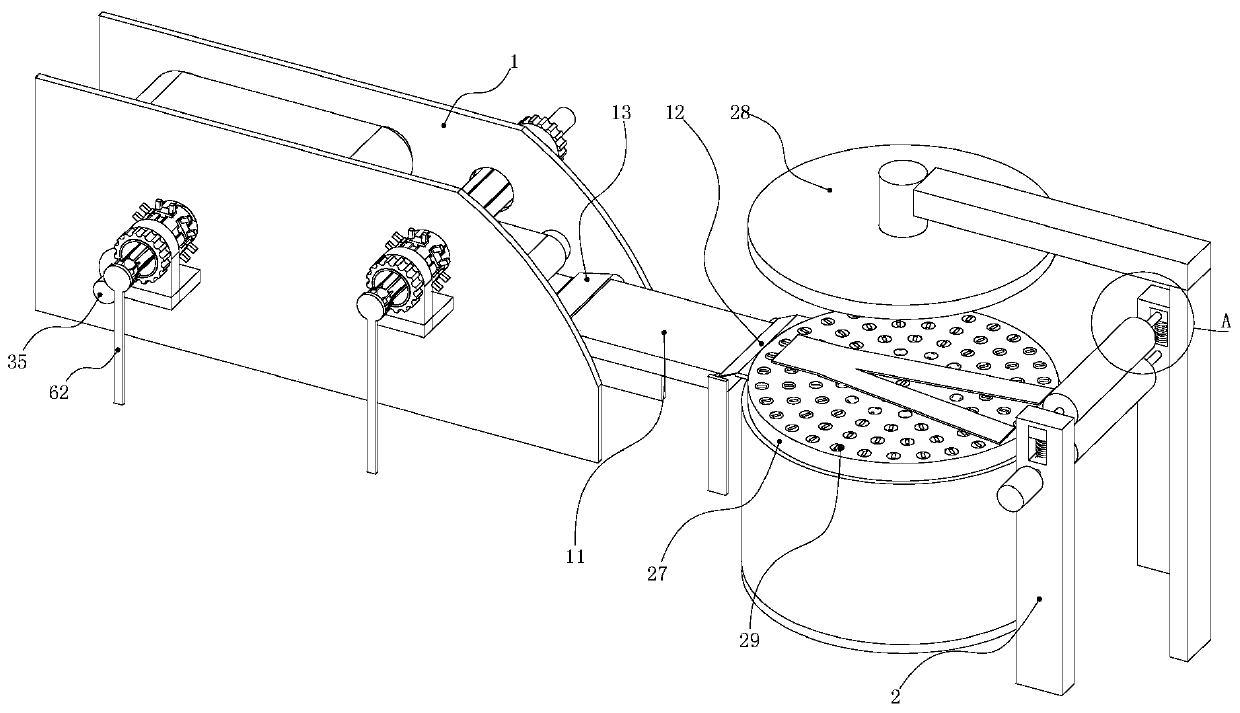

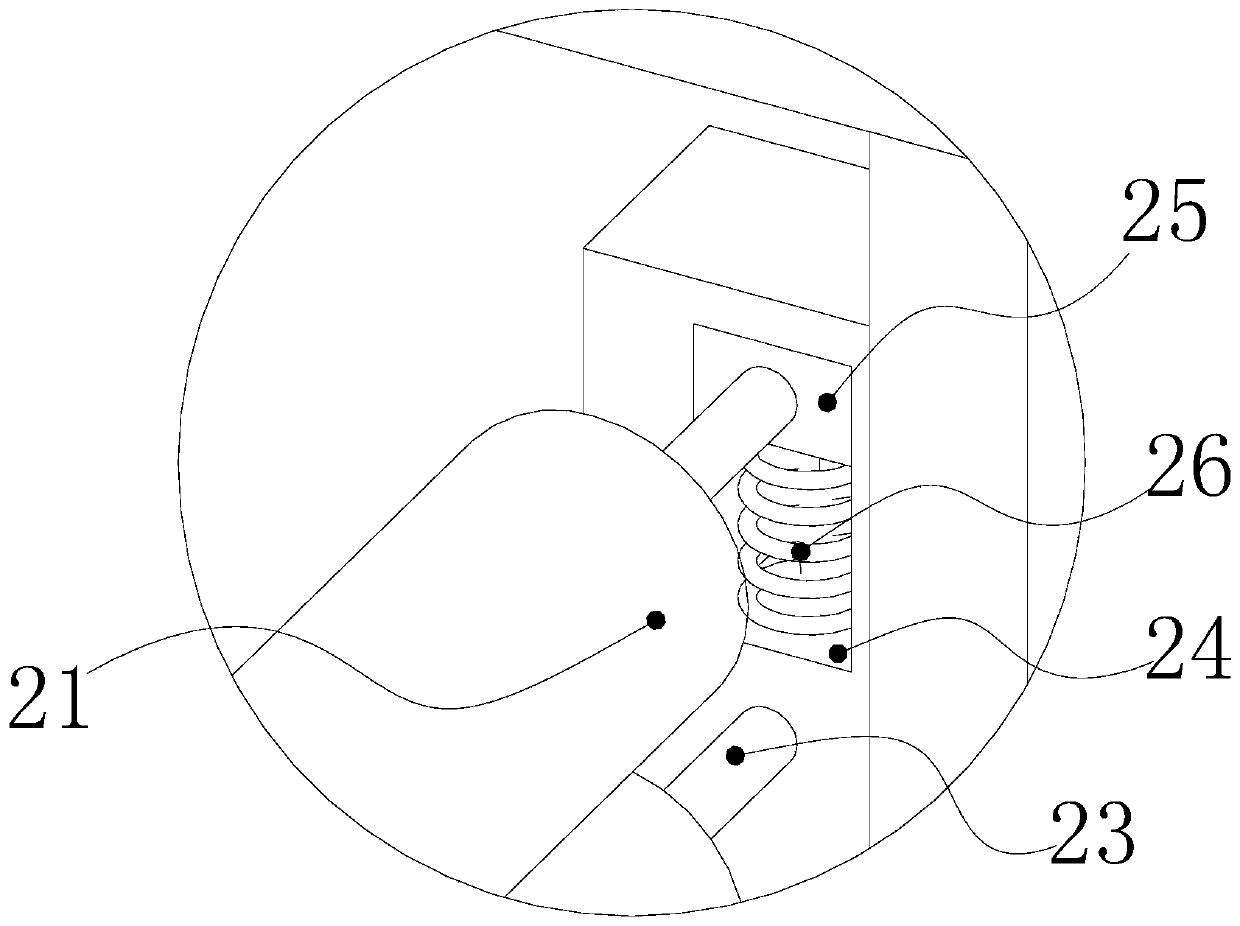

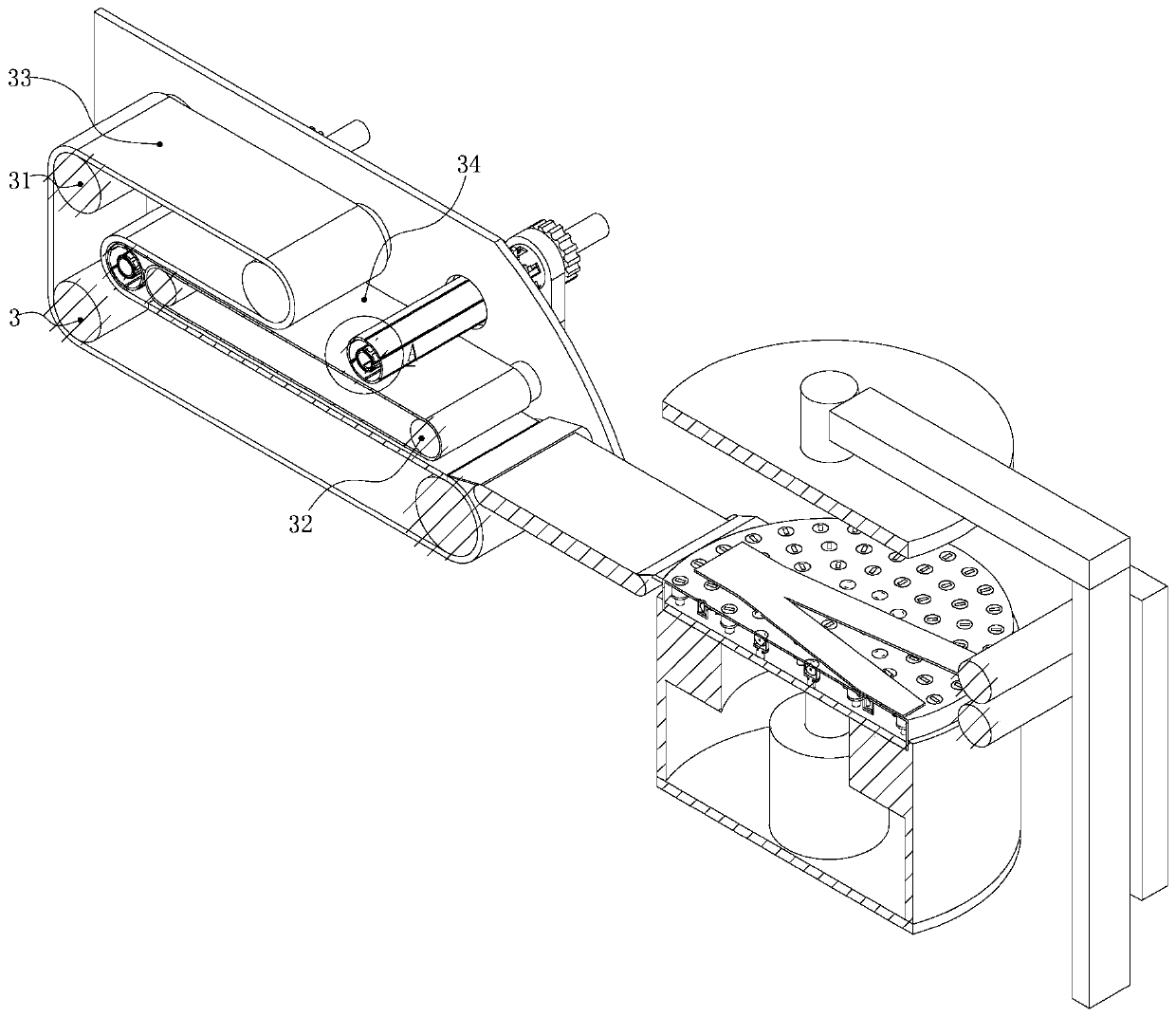

[0025] Such as Figure 1-10 As shown, a garment grinding machine includes a frame 1, a feeding device, a conveying device, a grinding device and a dust collection device. The feeding device includes a flattening mechanism, a positioning mechanism and a transport mechanism. The flattening The mechanism includes a fixed frame 2, a pressure roller 21, a pressure roller driver, a rotating shaft 23, a moving groove 24, a fixed block 25 and a first elastic member 26. The pressure roller 21 is a conventional round roller, which is symmetrically arranged on the fixed frame up and down. 2, when the clothes pass between the two rollers, the pressure rollers arranged up and down can squeeze the passing clothes, making the clothes surface smoother and convenient for subsequent laying. On the frame 2, the fixed block 25 is arranged in the moving groove 24 and can move up and down relative to the moving groove 24. The first elastic member 26 is a conventional metal spring, one end is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com