A kind of inorganic flame-retardant temperature-adjusting viscose fiber and preparation method thereof

An inorganic flame retardant and viscose fiber technology, which is applied to the artificial filament made of viscose and wet spinning method, can solve the problem of single function, achieve obvious temperature adjustment effect, accelerate solidification speed, improve safety and The effect of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

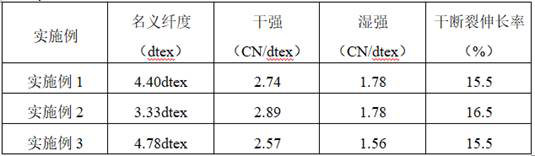

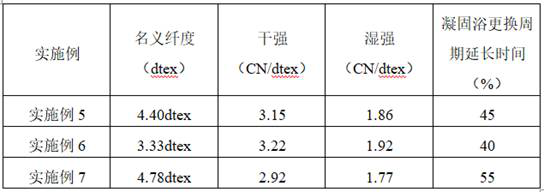

Embodiment 1

[0035] 1. Preparation of spinning dope:

[0036] Mix five batches of cotton and wood pulp with a degree of polymerization of about 950 and a cellulose content ≥ 95% in any proportion, then fully mix with the impregnating lye, and pass through 238±1g / L, 50℃ sodium hydroxide alkali solution After soaking for 60 minutes, press to make alkali cellulose; the alkali cellulose is crushed and aged, the aging temperature is 22°C, and the aging time is 1 hour; and then mixed with CS 2 Mix for yellowing reaction, the yellowing temperature is 18°C, the yellowing time is 60 minutes, and the amount of carbon disulfide added to methyl cellulose is 38% during yellowing to generate cellulose xanthate; cellulose xanthate is initially dissolved in dilute alkali solution After obtaining the spinning stock solution, add 3.5% denaturant to methyl fiber in the later stage of dissolution, which is composed of 2% polyethylene glycol and 1.5% hydroxyethylamine; Soak and mature to obtain spinning stock...

Embodiment 2

[0050] 1. Preparation of spinning dope:

[0051] Mix five batches of cotton and wood pulp with a degree of polymerization of about 1000 and a cellulose content ≥ 95% in any proportion, then fully mix with the impregnating lye, and pass through 238±1g / L, 49.8°C sodium hydroxide alkali solution After soaking for 60 minutes, press to make alkali cellulose; the alkali cellulose is crushed and aged, the aging temperature is 21.5°C, and the aging time is 1 hour; then it is mixed with CS 2 Mix for yellowing reaction, yellowing temperature is 18°C, yellowing time is 60 minutes, the amount of carbon disulfide added to methyl cellulose is 42% during yellowing, and cellulose xanthate is formed; cellulose xanthate is initially dissolved in dilute alkali solution After obtaining the spinning stock solution, add 4.2% denaturing agent to methyl fiber in the later stage of dissolving, and its composition is 2.7% PEG and 1.5% hydroxyethylamine; Mature to obtain the spinning dope. Spinning do...

Embodiment 3

[0065] 1. Preparation of spinning dope:

[0066] Mix five batches of cotton and wood pulp with a degree of polymerization of about 1200 and a cellulose content ≥ 95% in any proportion, then fully mix with the impregnating lye, and pass through 240±1g / L, 50℃ sodium hydroxide alkali solution After soaking for 60 minutes, press to make alkali cellulose; the alkali cellulose is crushed and aged, the aging temperature is 22.0℃, and the aging time is 1h; 2 Mix for yellowing reaction, yellowing temperature 18°C, yellowing time 60 minutes, add 45% of carbon disulfide to methyl fiber during yellowing to generate cellulose xanthate; cellulose xanthate is initially dissolved in dilute alkali solution After obtaining the spinning stock solution, add 4.0% denaturing agent to methyl fiber in the later stage of dissolving, and its composition is 2.5% PEG and 1.5% hydroxyethylamine; Mature to obtain the spinning dope. Spinning dope index: methyl fiber: 8.7wt%, containing 6.5% alkali, esteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com