High-temperature gasification nozzle for petroleum coke

A technology of petroleum coke and petroleum coke powder, which is applied in the gasification field of petroleum coke high temperature and high pressure entrained bed reactor, can solve the problem of low reaction activity, achieve the effects of increasing gasification reaction rate, small flow resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

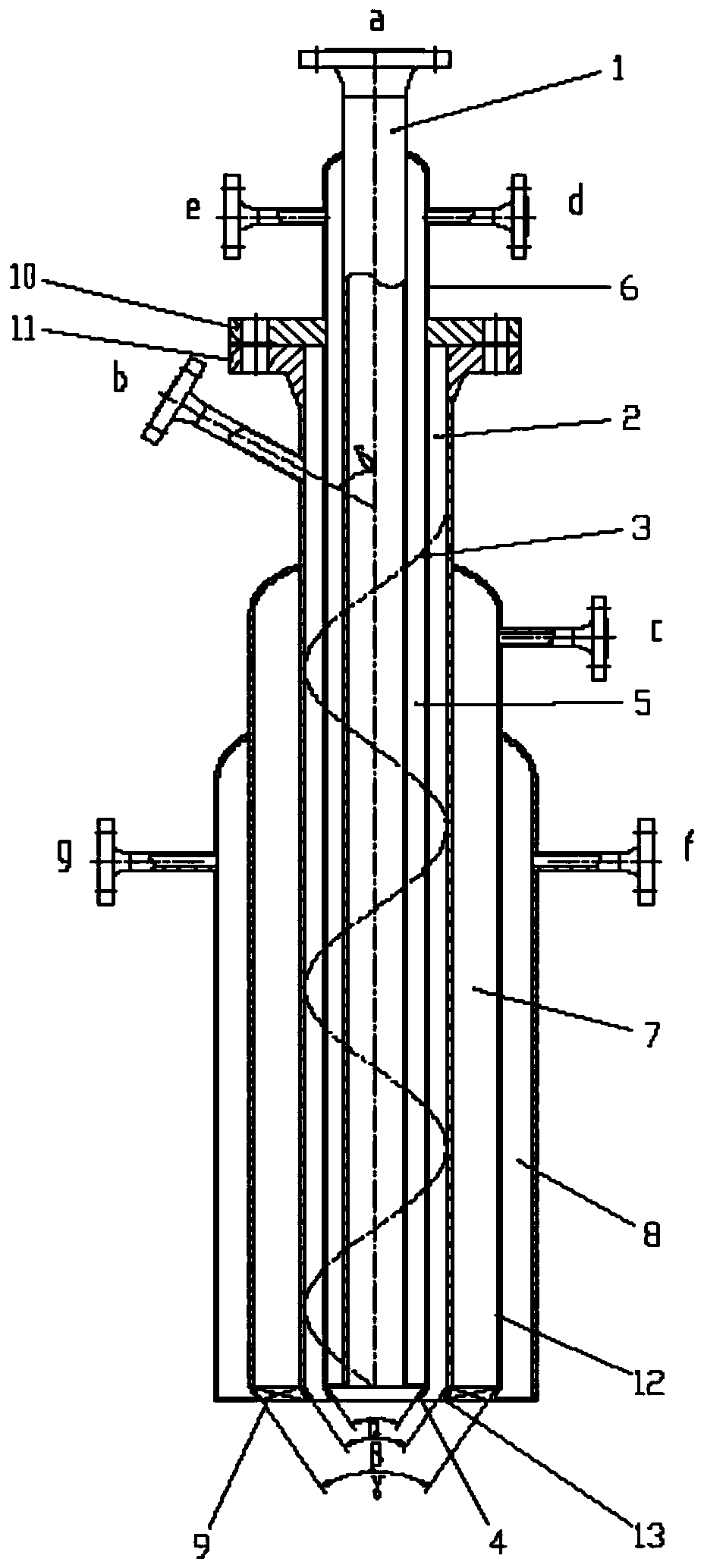

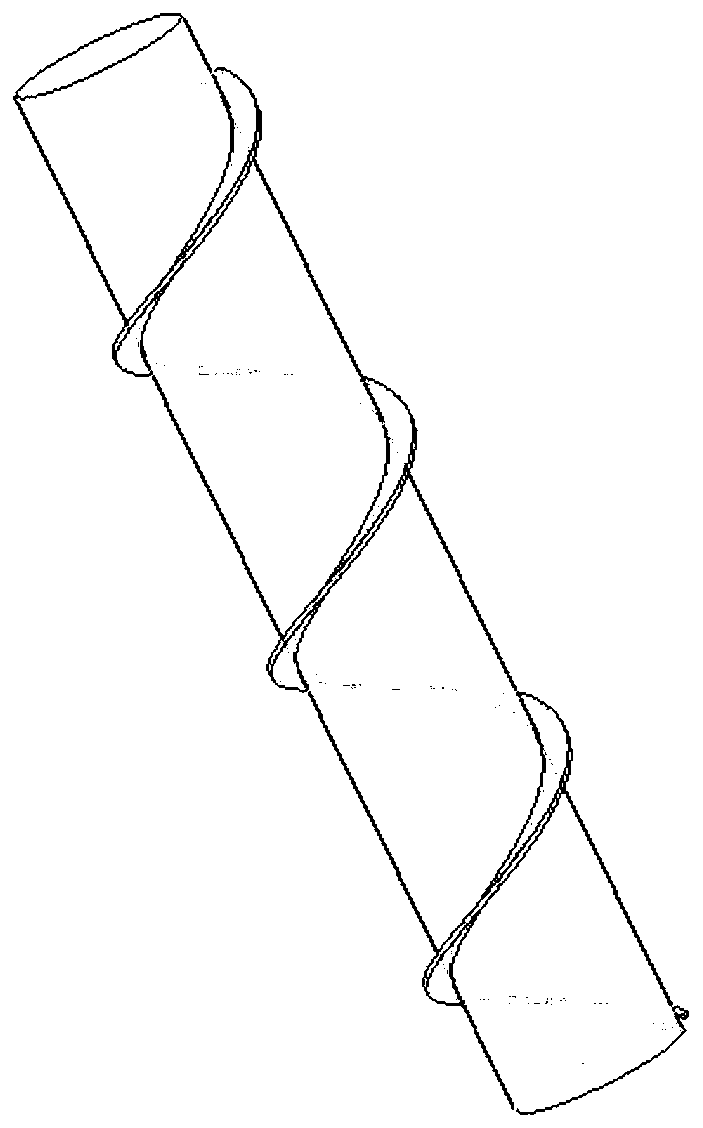

[0031] Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that these drawings are not necessarily drawn to scale.

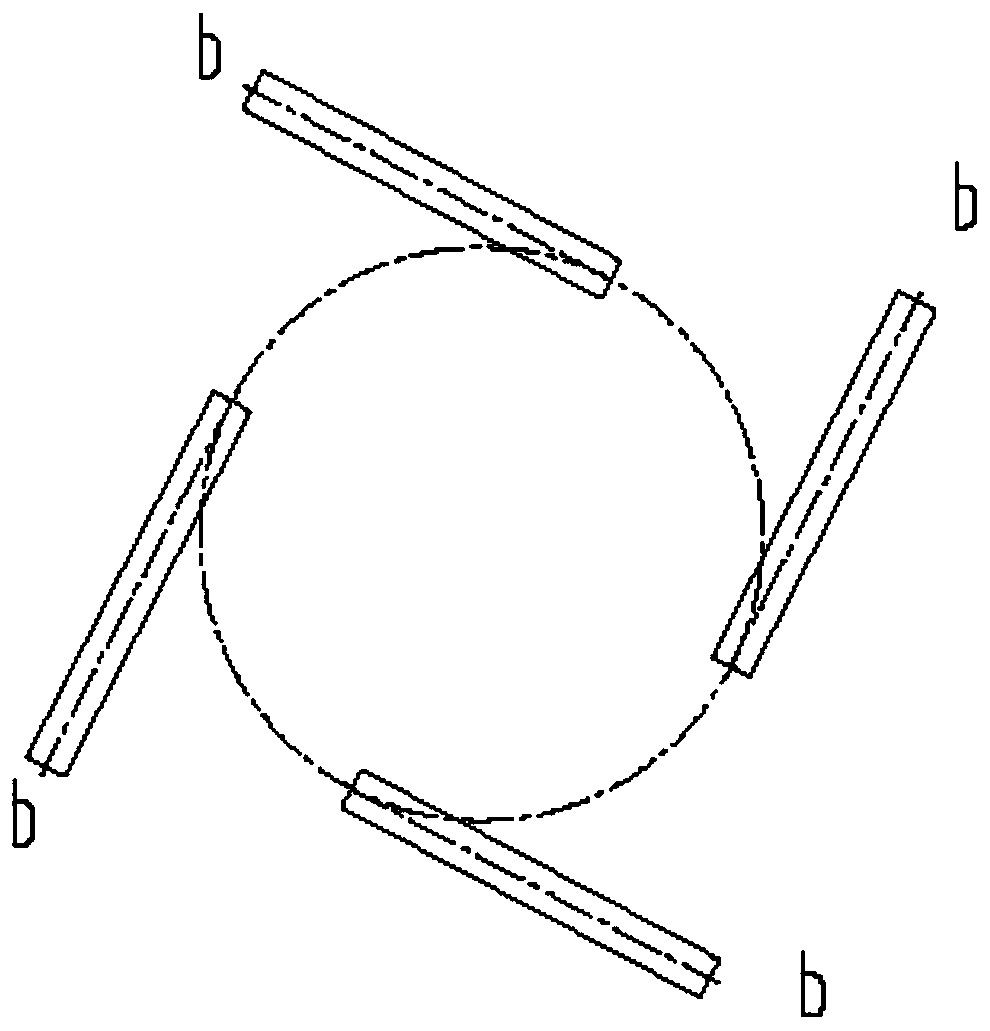

[0032] like figure 1 As shown, the present invention provides a petroleum coke high-temperature gasification nozzle, which is composed of a feed nozzle 6 and an auxiliary gasification agent nozzle 12, the feed nozzle 6 is coaxially inserted into the auxiliary gasification agent nozzle 12, and the feed nozzle 6 The feed nozzle flange 10 and the auxiliary gasification agent nozzle flange 11 of the auxiliary gasification agent nozzle 12 are sealed and connected; When the feeding requirement is met, the oven device can be pulled out, and then the feeding nozzle 6 can be inserted and installed.

[0033] The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com