Polyimide precursor solution, method for producing porous polyimide film, and porous polyimide film

A polyimide precursor, polyimide film technology, applied in the direction of coating, can solve the problems of low dispersibility, low substrate peelability, pinhole generation, etc., to achieve excellent dispersibility and improved peelability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0306] Examples are described below, but the present invention is not limited to these Examples. In addition, in the following description, unless otherwise specified, "part" and "%" are all based on mass.

[0307] [Preparation of inorganic particle dispersion]

[0308] As the inorganic particle dispersion liquid, the following silica particle dispersion liquid was prepared.

[0309] Silica particle dispersion (1): volume particle diameter 5nm solid content 20% by mass

[0310] Silica particle dispersion (2): volume particle diameter 13nm solid content 30% by mass

[0311] Silica particle dispersion (3): volume particle diameter 65nm solid content 40% by mass

[0312] Silica particle dispersion (4): volume particle diameter 210nm solid content 40% by mass

[0313] Silica particle dispersion (5): volume particle diameter 450 nm solid content 40% by mass

[0314] Silica particle dispersion (6): volume particle diameter 150 nm solid content 40% by mass

[0315] Titanium oxi...

Embodiment 2~18

[0337] In addition to changing the type and amount of the resin particle dispersion and the type and amount of the silica particle dispersion according to Table 2, resin particles and inorganic particle-dispersed polyimide precursor solutions (PAA- 2) ~ (PAA-18). The particle size distribution was measured for the resin particle and inorganic particle dispersion polyimide precursor solution of each example by the method already mentioned. The results are summarized in Table 2.

Embodiment 19

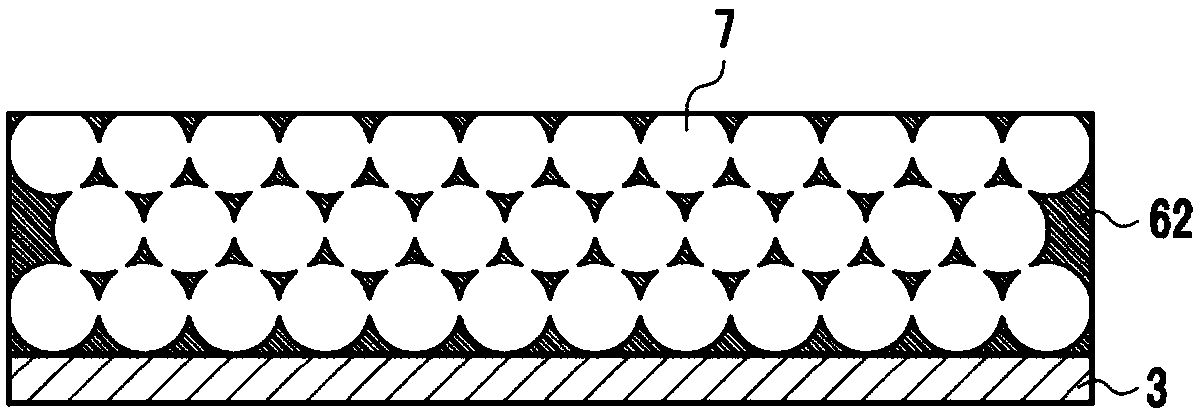

[0346] [Production of porous polyimide film (PIF-1)]

[0347] First, an aluminum substrate (hereinafter referred to as an aluminum substrate) for forming a coating film of a resin particle and an inorganic particle-dispersed polyimide precursor solution was prepared. The surface of the aluminum substrate was washed with toluene and used.

[0348] Next, resin particles and inorganic particle-dispersed polyimide precursor solution (PAA-1) were coated on the aluminum substrate so that the film thickness after drying was about 30 μm to form a coating film, and dried at 90° C. for 1 hour. Then, the temperature was raised from room temperature (25°C, the same below) to 400°C at a rate of 10°C / min, kept at 400°C for 1 hour, and then cooled to room temperature to obtain a porous polyimide film with a film thickness of about 25 μm. (PIF-1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com