Preparation method of graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite

A silicon carbide ceramic base and graphene modification technology, applied in the field of surface modification treatment, can solve the problems of poor mechanical properties of carbon fibers and silicon carbide ceramics, and achieve the effects of improving mechanical properties, increasing the bonding interface, and ensuring effective transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

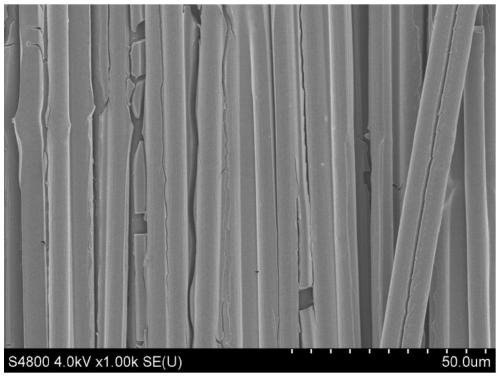

[0035] In this embodiment, the preparation method of a graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite material is as follows:

[0036] (1) Completely immerse the carbon fiber in acetone, heat it to reflux for 15 hours, take it out, and dry it at 60°C for 12 hours to obtain the dried carbon fiber. The dried carbon fiber is completely immersed in concentrated nitric acid and immersed at 60°C for 1.5 hours. After taking it out of concentrated nitric acid, wash the carbon fiber with deionized water to neutrality, and dry it at 60°C for 12 hours to obtain the carbon fiber with surface oxidation treatment;

[0037] (2) Disperse 50 mg of graphene oxide into 10 mL of ethanol, and add 2 mL of 5% silane coupling agent γ-aminopropyltriethoxysilane ethanol solution to obtain a silane coupling agent modified graphene oxide ethanol solution; Step (1) The prepared surface oxidation-treated carbon fiber is immersed in a silane coupling agent-modified graph...

Embodiment 2

[0051] In this embodiment, a method for preparing a graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite material, step (2) disperse 30 mg of graphene oxide in 10 mL of ethanol, and other things are the same as in embodiment 1.

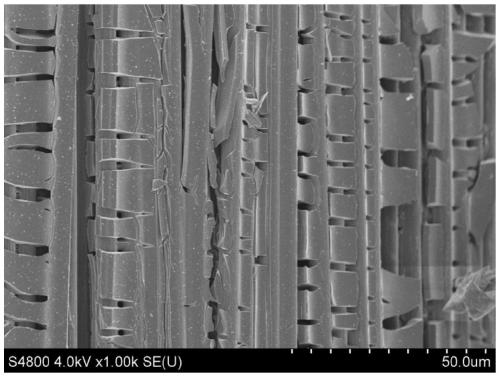

[0052] The graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite material prepared after the above operations is as Figure 4 As shown, it can be seen that almost all the cracks on the surface of the composite material are deflected. This is because the graphene oxide is reduced to graphene during the high temperature process to form an interface layer, which protects the internal carbon fibers from being easily physically and chemically affected. Damage, forming a weak interface bond, and can cause the cracks transmitted from the matrix to the carbon fiber to deflect at the interface layer.

Embodiment 3

[0054] In this embodiment, a method for preparing a graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite material, step (2) disperse 60 mg of graphene oxide in 10 mL of ethanol, and other things are the same as in embodiment 1.

[0055] The graphene oxide modified carbon fiber reinforced silicon carbide ceramic matrix composite material prepared after the above operations is as follows Figure 5 As shown, it can be seen that as the concentration of graphene oxide increases, there are fewer cracks on the surface of the composite material, and a small amount of cracks are deflected, making the bond between the carbon fiber and the silicon carbide matrix dense.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com