Method for preparing high-solid-phase content and low-viscosity ceramic slurry by using non-spherical ceramic particles

A technology of ceramic particles and ceramic slurry, which is applied in the field of preparation of high solid phase content and low viscosity ceramic slurry, can solve the problems of shortage, large amount of engineering, lack of quantitative shape description methods for irregular ceramic particles, etc., to achieve Performance and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing ceramic slurry for gel injection molding with high solid phase content and low viscosity by using non-spherical ceramic particles disclosed by the present invention comprises the following steps:

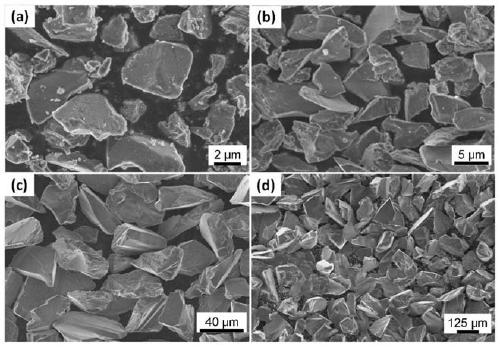

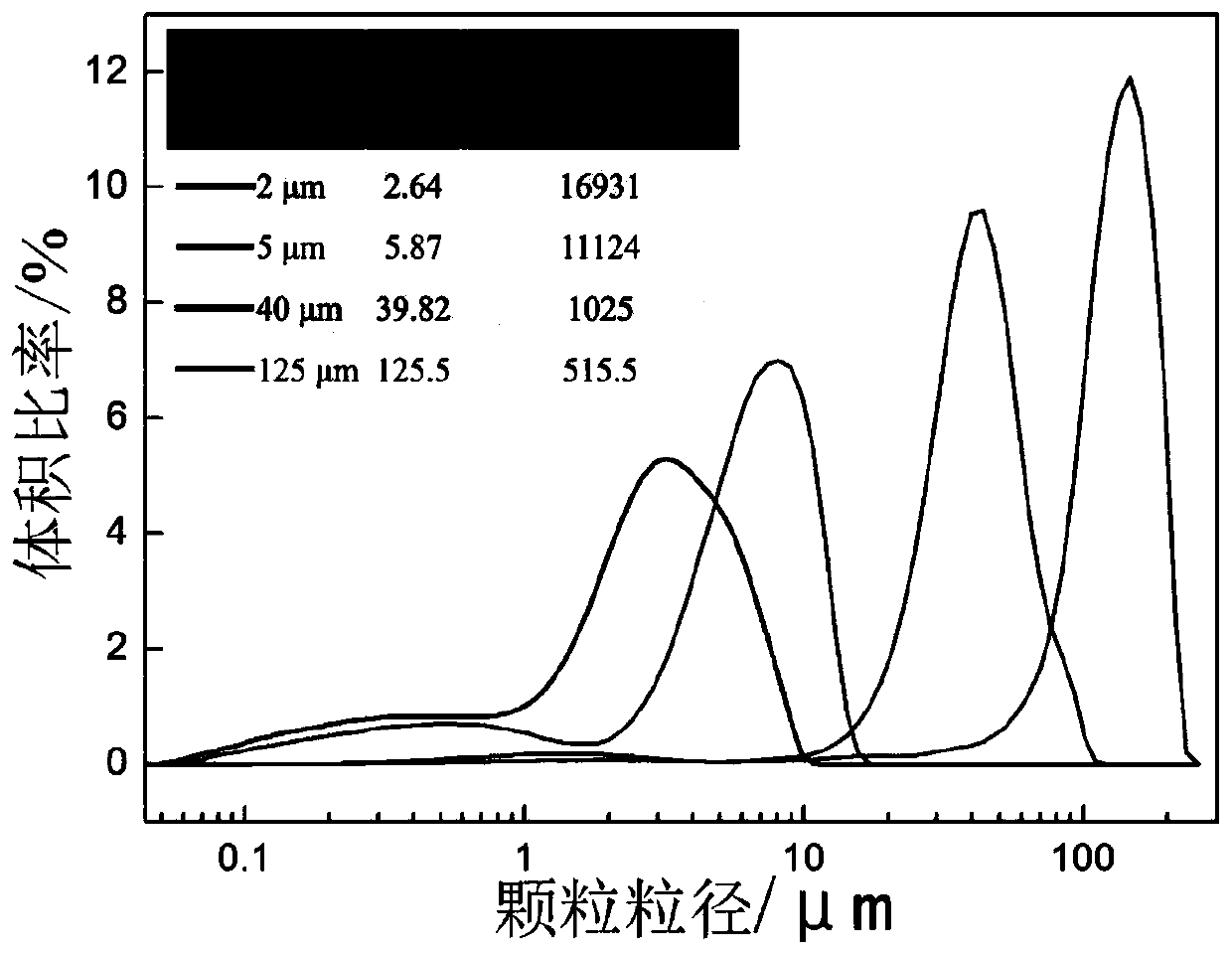

[0044] 1) Selection and morphology characterization of ceramic powder materials

[0045] The ceramic powder is made of ceramic powders of different thicknesses prepared by the same process method, and the particle morphology is roughly screened by scanning electron microscopy to determine whether the ceramic particles have similar geometric shapes; at least two or more particle sizes of ceramics are selected. For powder, the particle size ratio of adjacent particles is greater than 2, the selected minimum particle size should be greater than 1 μm, and the maximum particle size should be less than 150 μm. Use a laser particle size analyzer to analyze the particle size of the selected ceramic particles, measure the particle size distribution curve, median...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com