Preparation method of oily sludge based adsorption carbon material for oily sewage treatment

A technology for sewage treatment and carbon adsorption, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of high equipment strength requirements, small equipment strength requirements, and the amount of pore-enlarging agent. Large and other problems, achieve the effect of reducing preparation cost, low price, and good degreasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

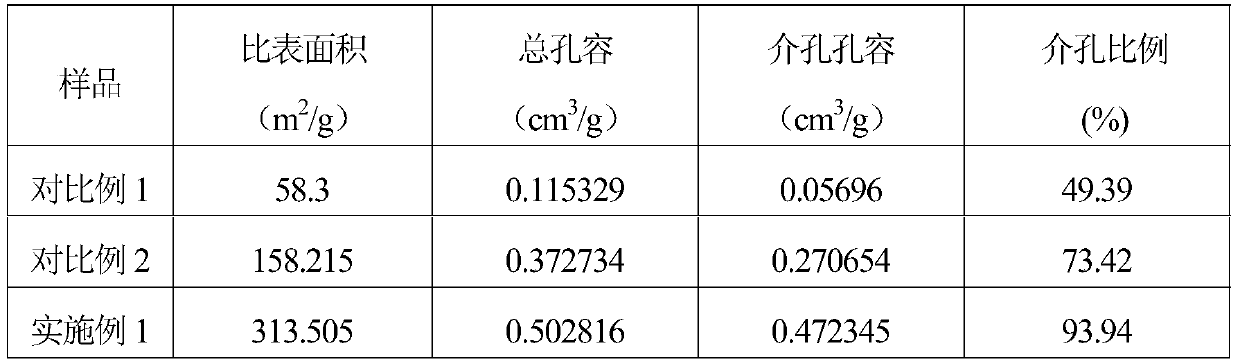

Examples

Embodiment 1

[0023] 1. Dry the reduced oily sludge with a water content of 62.2% and an oil content of 8% produced in the process of oil exploitation and refining to a water content of 9% and an oil content of 7.2%, to obtain dry sludge Mud: Grind the dry sludge, almond shell and cotton seeds to a particle size of 20-40 mesh, then mix 5.0g of dry sludge particles, 3.5g of almond shell particles, and 1.5g of cotton seed particles evenly, A raw material mixture is obtained.

[0024] 2. Mix the raw material mixture obtained in step 1 with 4 g of ethanolamine, and heat-treat at 80° C. for 4 hours.

[0025] 3. According to the material-to-liquid ratio of 1g:1.5mL, the heat-treated product obtained in step 2 was added to the industrial waste alkali solution, and soaked at room temperature for 24 hours. The total mass concentration of sodium hydroxide and sodium carbonate in the industrial waste alkali solution used was 30%; After impregnation, it was dried at 105°C to constant weight to obtain ...

Embodiment 2

[0033] 1. Dry the oily sludge with a water content of 64.1% and an oil content of 6.7% after reduction treatment produced in the process of oil exploitation and refining to a water content of 8% and an oil content of 6.1% to obtain dry sludge Sludge: Grind the dry sludge, almond shells, and grape seeds to a particle size of 20-40 meshes, then mix 6.0g of dry sludge particles, 3.0g of almond shell particles, and 1.0g of cotton seed particles evenly, A raw material mixture is obtained.

[0034] 2. Mix the raw material mixture obtained in step 1 with 3 g of ethanolamine, and heat-treat at 100° C. for 3 hours.

[0035] 3. According to the material-liquid ratio of 1g:2.5mL, the heat-treated product obtained in step 2 was added to the industrial waste alkali solution, and soaked at room temperature for 24 hours. The total mass concentration of sodium hydroxide and sodium carbonate in the industrial waste alkali solution used was 35%; After impregnation, it was dried at 105°C to con...

Embodiment 3

[0039] 1. Dry the oily sludge with a water content of 61.5% and an oil content of 9.8% after reduction treatment produced in the process of oil exploitation and refining to a water content of 7.5% and an oil content of 8.9%, to obtain dry sludge Sludge: Grind dry sludge, pistachio shells, cotton seeds, and watermelon seeds to a particle size of 20-40 meshes, and then mix 5.0g of dry sludge granules, 3.5g of pistachio shell granules, 0.75g of cotton seed granules and 0.75 g Watermelon seed granules are mixed well to obtain a raw material mixture.

[0040] 2. Mix the raw material mixture obtained in step 1 with 3 g of ethanolamine, and heat-treat at 120° C. for 5 hours.

[0041] 3. According to the material-liquid ratio of 1g:2mL, add the heat-treated product obtained in step 2 into the industrial waste alkali solution, and soak for 24 hours at room temperature. The total mass concentration of sodium hydroxide and sodium carbonate in the industrial waste alkali solution used is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com