A four-track bed

A technology of rail bed and inclined bed, applied in the field of four-rail bed, can solve the problems of affecting the accuracy of processing, difficult to clean, shorten the service life of guide rails, etc., and achieve the effects of improving rigidity, convenient operation and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

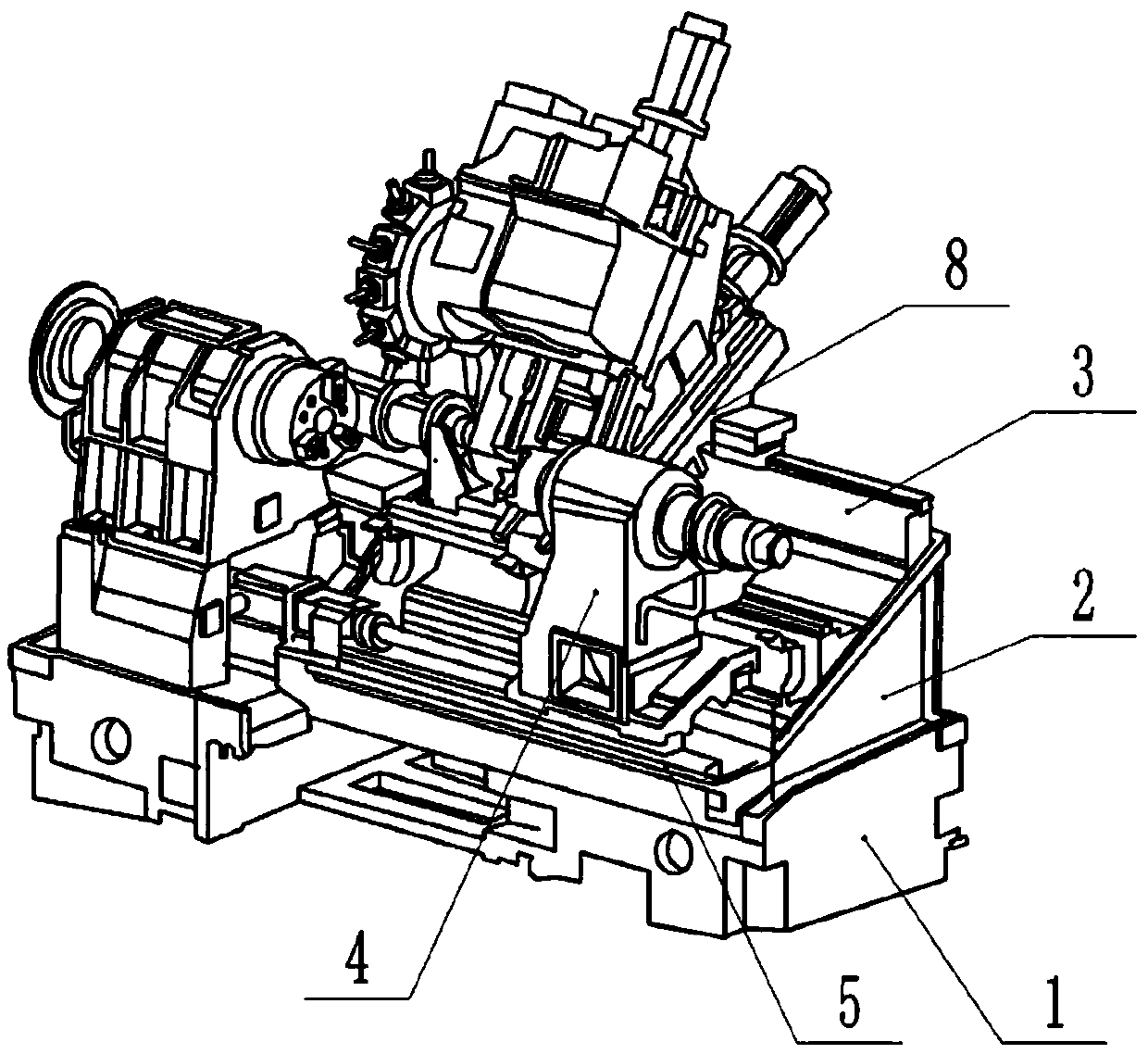

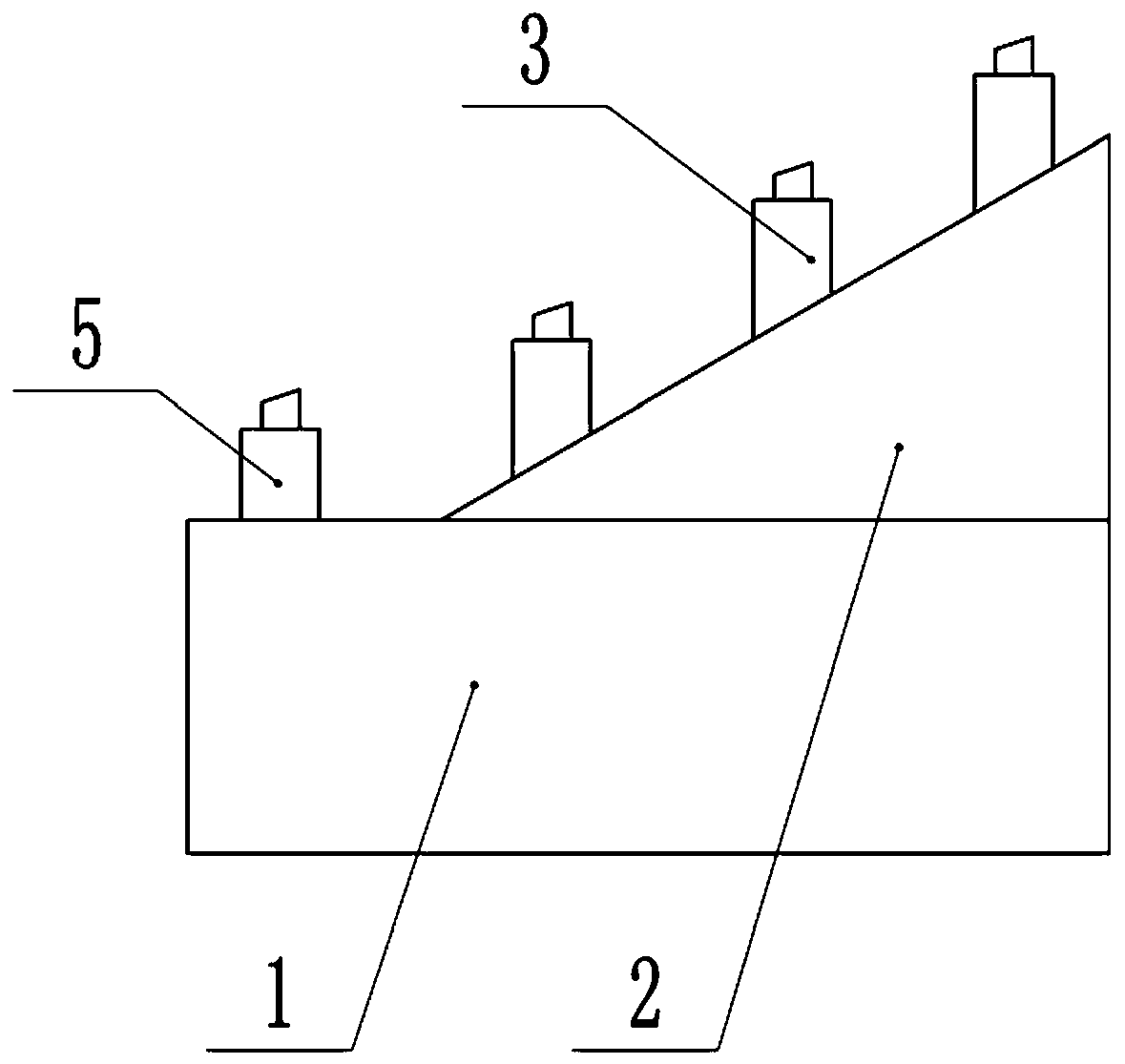

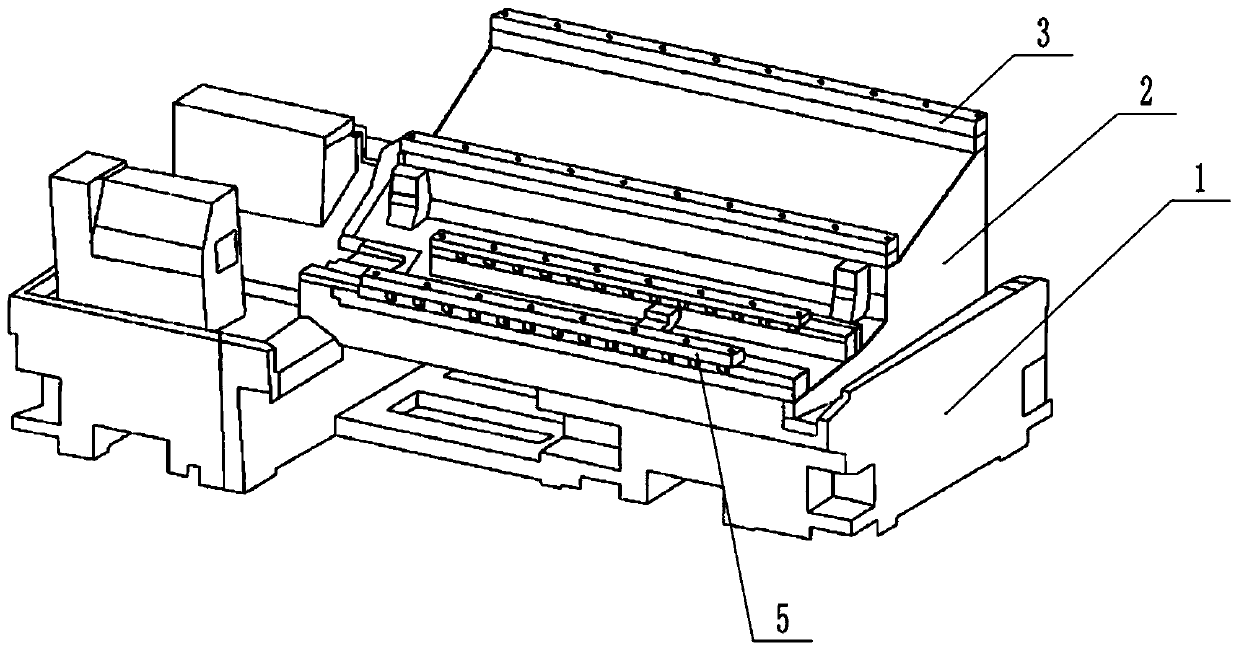

[0032] Basic as attached image 3 Shown: a four-rail bed, including a base 1, an inclined bed 2, a tailstock guide 5 and a saddle guide 3, the inclined bed 2 is fixed on the base 1 by screws, and the saddle guide 3 is fixed on the inclined bed 2, the tailstock guide rail 5 is fixed on the top surface of the base 1, and the top surface of the base 1 is a plane and parallel to the horizontal plane. The top surface of the tailstock guide rail 5 and the top surface of the saddle guide rail 3 are all parallel to the top surface of the base 1; They are all on the same plane and parallel to the top surface of the base 1 . Saddle rail 3 for use in figure 1 The middle saddle assembly 8 slides, and the tailstock guide rail 5 is used to make the tailstock assembly 4 slide.

[0033] A cleaning assembly for cleaning the tailstock guide rail 5 is provided on the base 1 . In this embodiment, the cleaning assembly includes an air blowing pump and an air blowing pipe, the air blowing pipe ...

Embodiment 2

[0038] combine Figure 4 As shown, the cleaning assembly in this embodiment includes two sides of tailstock guide rail 5 Figure 4 The rotating disk 10 in the middle, the rotating disk 10 rolls on the base 1 along the length direction of the tailstock guide rail 5, and a rotating shaft 23 is connected between the two rotating disks 10, and the two ends of the rotating shaft 23 pass through the rotating disk 10 and are welded on the On the inner wall of the rotating disk 10 away from the tailstock guide rail 5, the middle part of the rotating shaft 23 is connected with a bearing 19 for rotation. Specifically, the bearing 19 is sleeved in the middle part of the rotating shaft 23, and the inner ring of the bearing 19 is welded to the rotating shaft 23; of course, it can not be used here. The bearing 19 may be rotatably connected with the rotating shaft 23 through a sleeve. combine Figure 5 As shown, the cleaning assembly also includes a driving block 20, the driving block 20 i...

Embodiment 3

[0044] In this embodiment, the rotating disk 10 is provided with several openings on the side away from the tailstock guide rail 5, and a cover is provided on the openings. When the iron filings in the cavity are almost collected, the cover can be taken out, the opening is opened, and the iron Chips are automatically discharged from the opening, thereby realizing the discharge of iron filings. Of course, the cavity is detachably connected with a magnet bar. If there is a groove on the inner wall of the cavity, insert the magnet bar in the groove, and the magnet bar can collect the iron filings in the cavity. When the iron filings are full, , open the cover, and take out the magnet bar from the opening, so as to realize taking out the iron filings from the cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com