A simple three-dimensional positioning installation and load-bearing device and its application method

A three-dimensional positioning and simple technology, which is applied in hoisting devices, portable lifting devices, transportation and packaging, etc., can solve problems such as low precision, complicated installation work, hidden safety hazards, etc., and achieve uniform force, uniform gravity, and convenient adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

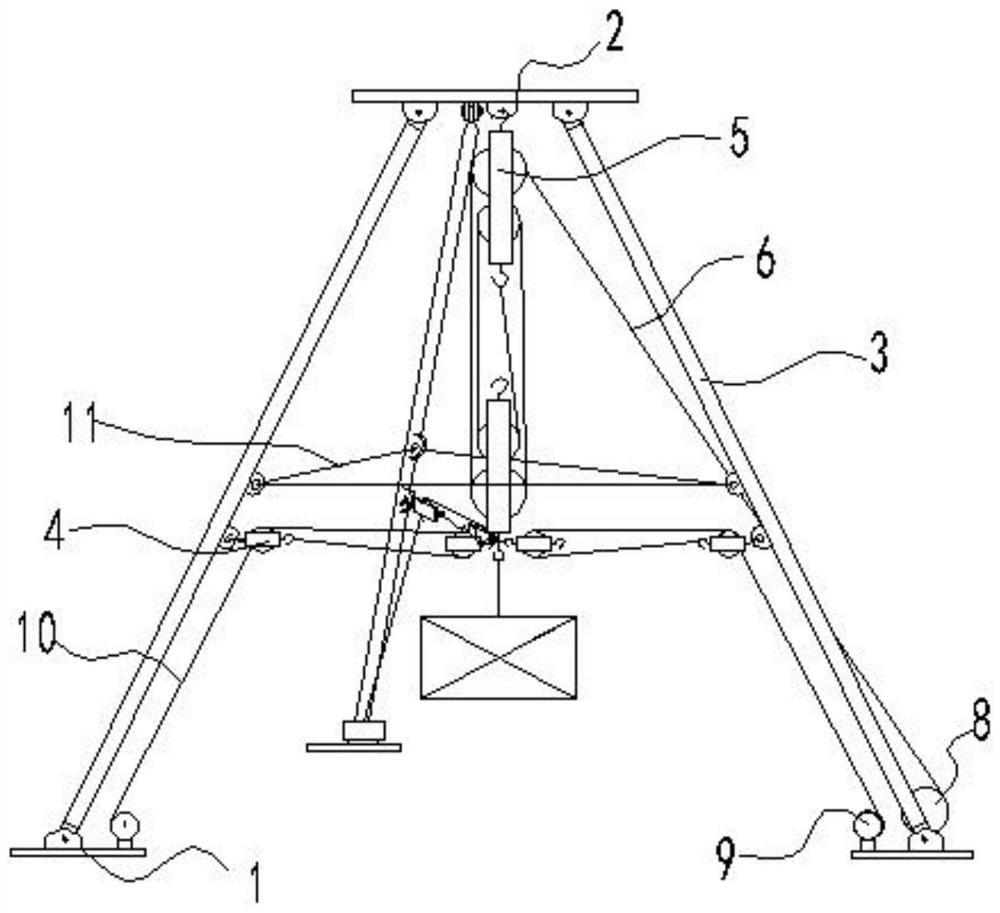

[0048] combine Figure 1 to Figure 10 As shown, a simple three-dimensional positioning installation and load-bearing device proposed by the present invention includes a load-bearing part, a lifting part and an adjusting part;

[0049] The load-bearing part includes a backing plate 1, a load-bearing plate 2 and a load-bearing rod 3.

[0050] The side of the backing plate 1 close to the load-bearing plate 2 is respectively welded and connected with the second connection block 7 with a thickness of 12mm and the first hoist 9 with a thickness of 12mm by bolts.

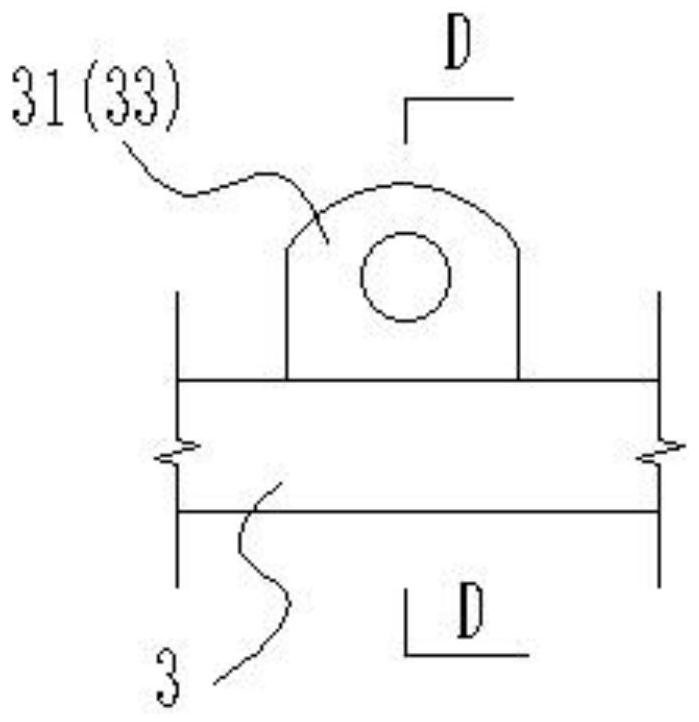

[0051] The side of the load-bearing plate 2 close to the backing plate 1 is welded and connected with a first load-bearing block 21 with a thickness of 12 mm and a first connection block 22 with a thickness of 12 mm, and the first load-bearing block 21 is located at the center of the load-bearing plate 2 , can make the bearing plate 3 evenly stressed. The first connecting block 22 is evenly arranged in three groups in th...

Embodiment 2

[0059] The invention also discloses a method for using a simple three-dimensional positioning installation and load-bearing device, which includes the following steps:

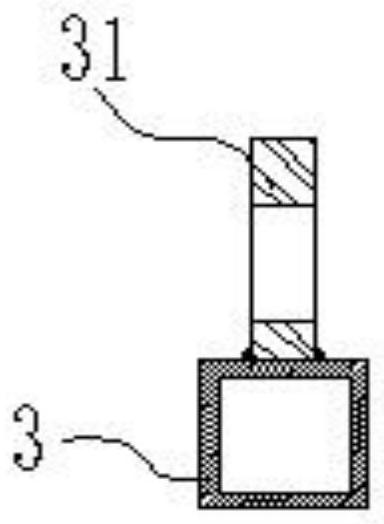

[0060] Step 1. Fix the side of all load-bearing rods 3 connected to the limit block 31 towards the inside of the overall device;

[0061] Step 2, all the third connection blocks 32 at the end away from the backing plate 1 are connected to the first connection block 21 with 12mm bolts;

[0062] Step 3, all the third connecting blocks 32 far away from the end of the bearing plate 2 are connected to the second connecting block 7 with 12mm bolts;

[0063] Step 4: The end of the first pulley group 5 away from the backing plate 1 is hooked to the first load-bearing block 21, and the end of all the second pulley groups 4 close to the load-bearing rod 3 is hooked to the second load-bearing block 33, and the second pulley group 4 is far away from the second load-bearing block. One end of the block 33 is hooked with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com