Inspection robot

A technology of inspection robot and walking mechanism, which is applied in the field of inspection robot, can solve the problems of high cost and large amount of equipment investment, and achieve the effect of balanced gravity, compact structure and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

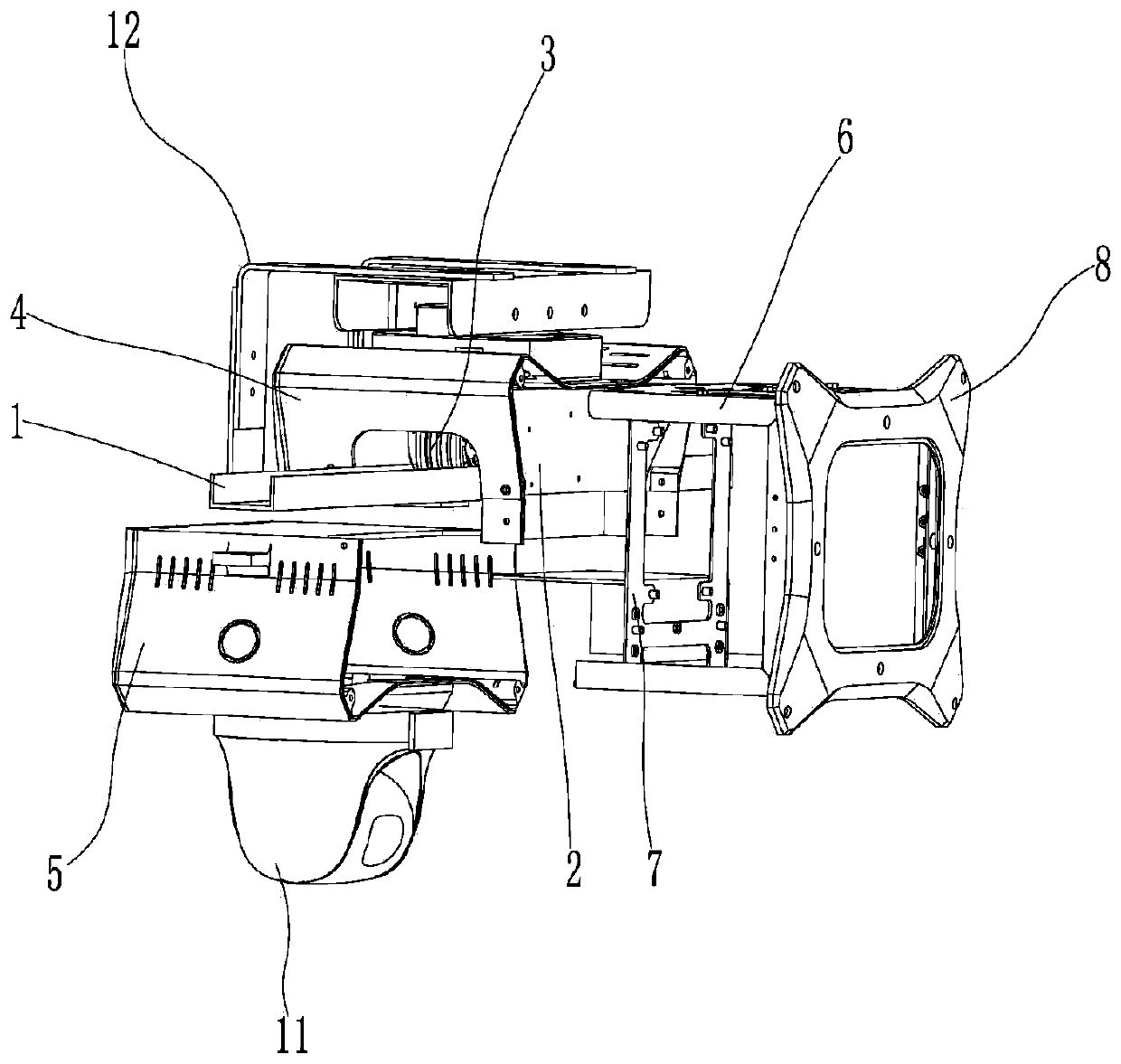

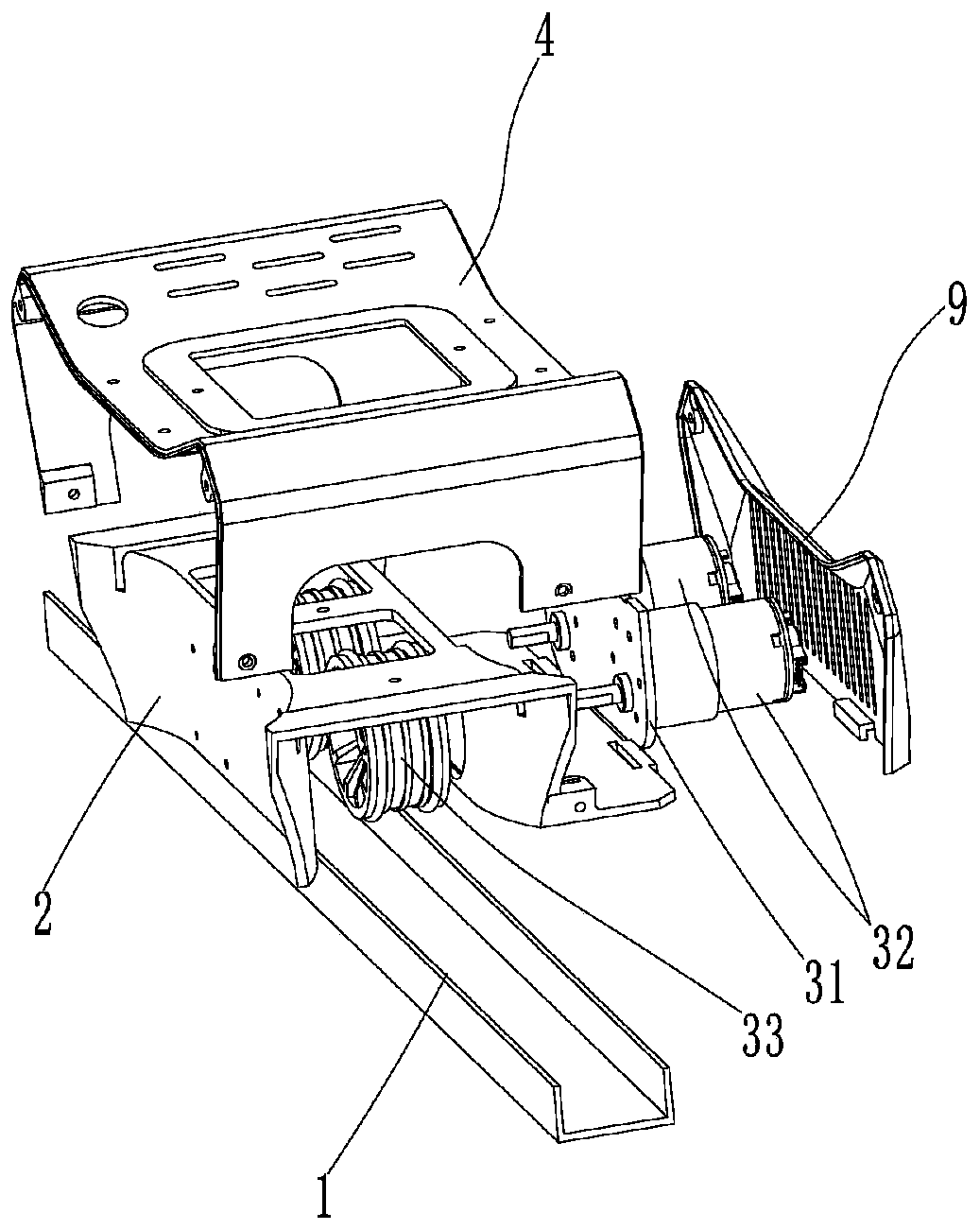

[0027] Such as Figure 1 to Figure 6 As shown, the present invention provides a kind of patrolling robot, comprises the annular rail 1 that cross section is groove shape, and described annular rail 1 is erected with protective shell 2, and described protective shell 2 is installed on the circular rail 1 moving The traveling mechanism 3, the traveling mechanism 3 comprises a motor connection plate 31 detachably installed on the inner side plate of the protective shell 2, two drive motors 32 are installed at intervals on the motor connection plate 31, and the rotation shafts of the two drive motors 32 extend Into the protective shell 2 and installed with a roller 33, the roller 33 is placed in the ring track 1 to roll, when the two drive motors 32 run, the drive roller 33 rolls in the ring track 1, thereby driving the whole machine on the ring track 1 move up. An upper casing 4 positioned above the casing 2 and a lower casing 5 positioned below the circular track 1 are installe...

Embodiment 2

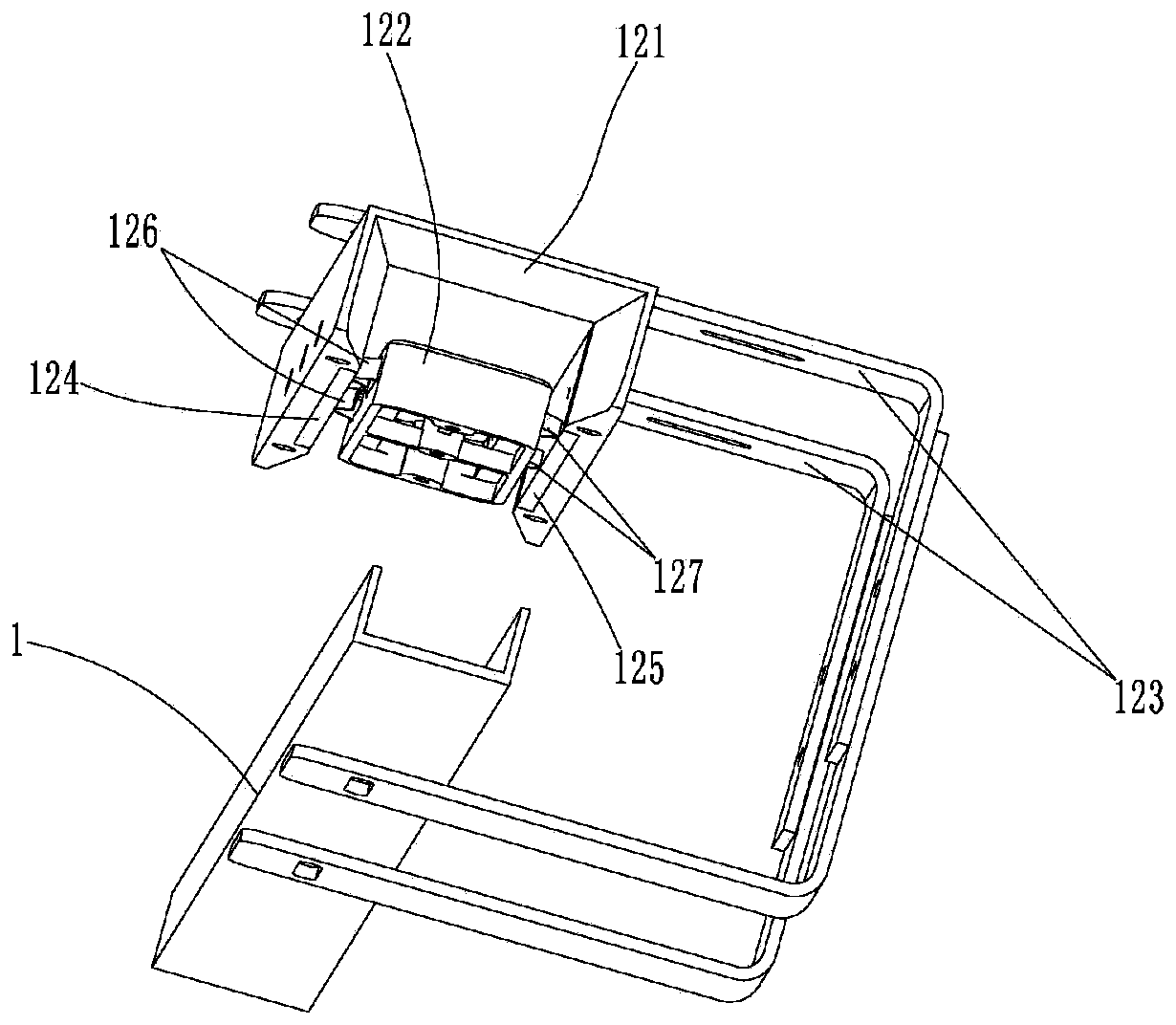

[0036] Such as Figure 7 ~ Figure 8 As shown, in order to further improve the charging contact mode of the charging position, on the basis of Embodiment 1, the positive electrode sheet 126 is replaced by the positive electrode contact column 13, and the negative electrode sheet 127 is replaced by the negative electrode contact column 14, so The power receiving seat 122 is replaced with a contact column mounting seat 15, and the positive electrode contact column 13 and the negative electrode contact column 14 are slidably installed on the contact column mounting seat 15 through a spring, and the contact column mounting seat 15 The limited cover plate 16 is installed inside; when in use, both the positive electrode contact column 13 and the negative electrode contact column 14 are connected to the rechargeable lithium battery through wires, and when the whole moves to the position of the charging base 121, the positive electrode contact The column 13 is in elastic contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com