Ultrafine metal nano frame and preparation method thereof

A metal nano and nano technology, applied in the field of nano materials and their preparation methods, can solve the problems of lack of plasmon resonance performance and restrict application, and achieve the effects of mild conditions, simple preparation conditions and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

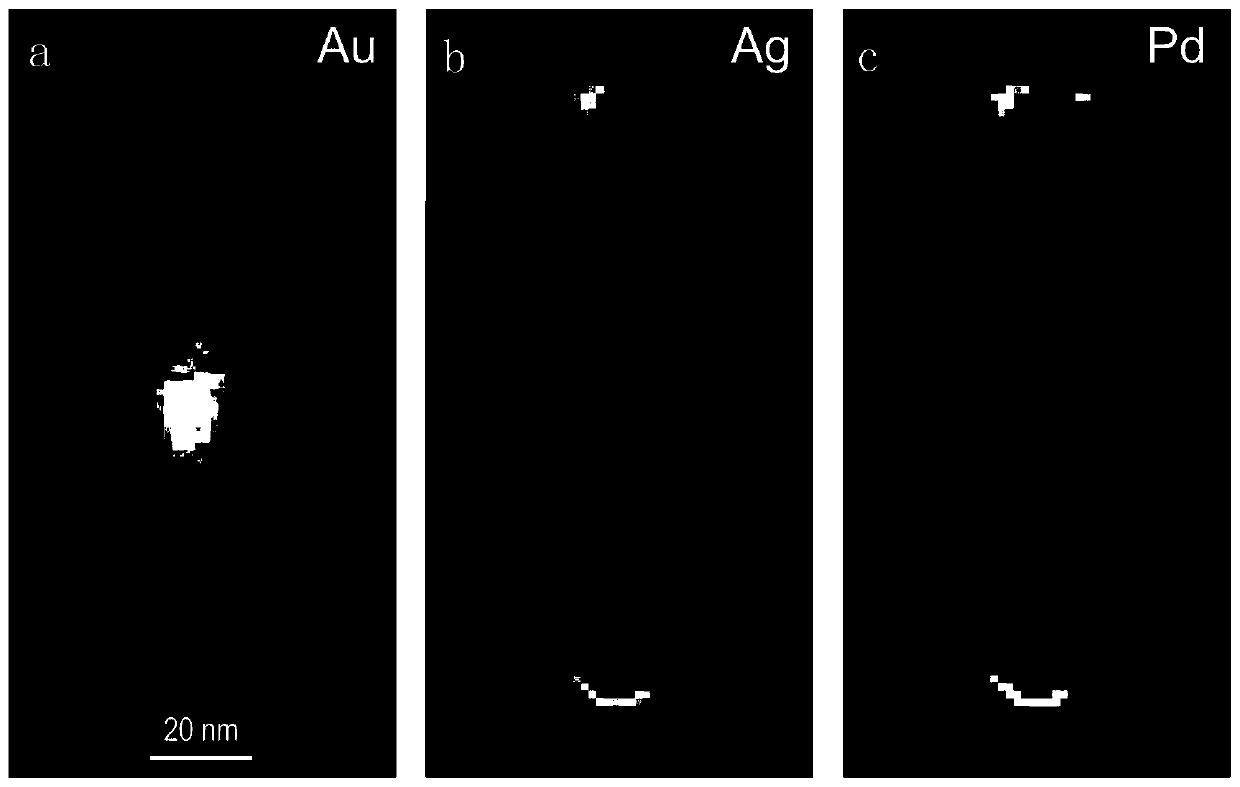

Image

Examples

Embodiment 1

[0018] Step 1, add 1mL gold nano biconical solution to 10mL, 0.08mol / L cetyltrimethylammonium chloride solution, then add 250μL, 0.01mol / L silver nitrate solution and 125μL, 0.1mol / L Ascorbic acid solution, the obtained mixed solution was shaken and put into a 60°C oven for 5h to react to obtain silver nanorods;

[0019] Step 2, silver nanorods are centrifuged at 5000rpm for 10min, then dispersed in 4mL, 0.05mol / L cetyltrimethylammonium bromide solution, add 1mL, 0.2mol / L sodium hydroxide solution and 1mL, 0.1mol / L ascorbic acid solution, slowly add 1.6mL, 0.1mmol / L chloropalladium acid reaction solution dropwise at a rate of 20μL / min at room temperature, and the reaction time is 2h;

[0020] Step 3, centrifuge the sample obtained in step 2 at 6000rpm for 10min, then disperse in 3mL, 0.005mol / L cetyltrimethylammonium bromide solution, add 0.1mL, 14mol / L ammonia solution and 2mL, 5mol / L hydrogen peroxide solution, and react at room temperature for 12 hours to obtain ultrafine...

Embodiment 2

[0024] Step 1, add 1mL gold nano biconical solution to 50mL, 0.01mol / L cetyltrimethylammonium chloride solution, then add 600μL, 0.01mol / L silver nitrate solution and 300μL, 0.1mol / L ascorbic acid solution, shake the obtained mixed solution and put it in a 40°C oven for 8 hours to obtain silver nanorods;

[0025] Step 2, centrifuge the silver nanorods at 5000rpm for 10min, then disperse them in 4mL, 0.01mol / L cetyltrimethylammonium bromide solution, add 1mL, 0.1mol / L sodium hydroxide solution and 1mL, 0.1mol / L ascorbic acid solution, slowly add 2mL, 0.1mmol / L chloroauric acid reaction solution dropwise at a rate of 10μL / min at room temperature, and the reaction time is 1h;

[0026] Step 3, centrifuge the sample obtained in step 2 at 6000rpm for 10min, then disperse in 10mL, 0.003mol / L cetyltrimethylammonium bromide solution, add 10mL, 1mol / L ammonia solution and 20mL, 1mol / L ammonia solution respectively L hydrogen peroxide solution, reacted at room temperature for 24 hours t...

Embodiment 3

[0028] Step 1, add 1mL gold nano biconical solution to 10mL, 0.1mol / L cetyltrimethylammonium chloride solution, then add 10μL, 0.1mol / L silver nitrate solution and 10μL, 1mol / L ascorbic acid solution , shake the obtained mixed solution and put it in an oven at 80°C for 1 hour to react to obtain silver nanorods;

[0029] Step 2, centrifuge the silver nanorods at 5000rpm for 10min, then disperse them in 4mL, 0.05mol / L cetyltrimethylammonium bromide solution, add 0.1mL, 1mol / L sodium hydroxide solution and 0.1mL , 1mol / L ascorbic acid solution, and slowly add 0.1mL, 0.5mmol / L chloropalladium acid reaction solution dropwise at a rate of 30 μL / min at room temperature, and the reaction time is 3h;

[0030] Step 3, centrifuge the sample obtained in step 2 at 6000rpm for 10min, then disperse in 10mL, 0.1mol / L cetyltrimethylammonium bromide solution, add 0.1mL, 14mol / L ammonia solution and 0.5mL, 5mol / L hydrogen peroxide solution, and react at room temperature for 24 hours to obtain u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com