Novel broadeningequipment

A new type of equipment and technology, applied in drilling equipment and methods, drilling equipment, earth-moving drilling, etc., can solve the problems of low concentricity, low hole reaming efficiency, prone to collapse, etc., to ensure concentricity and improve hole reaming. Efficiency, the effect of avoiding offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

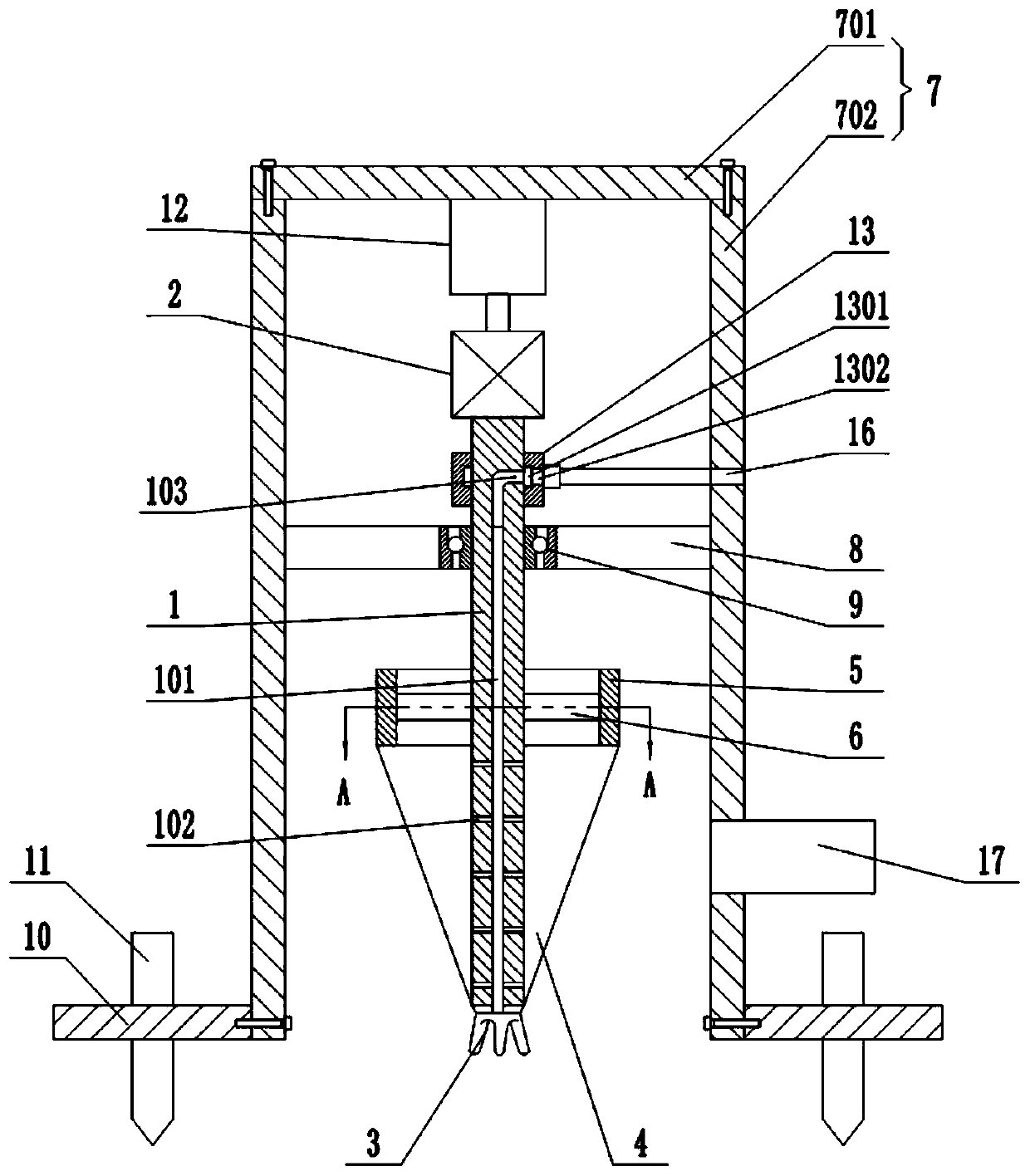

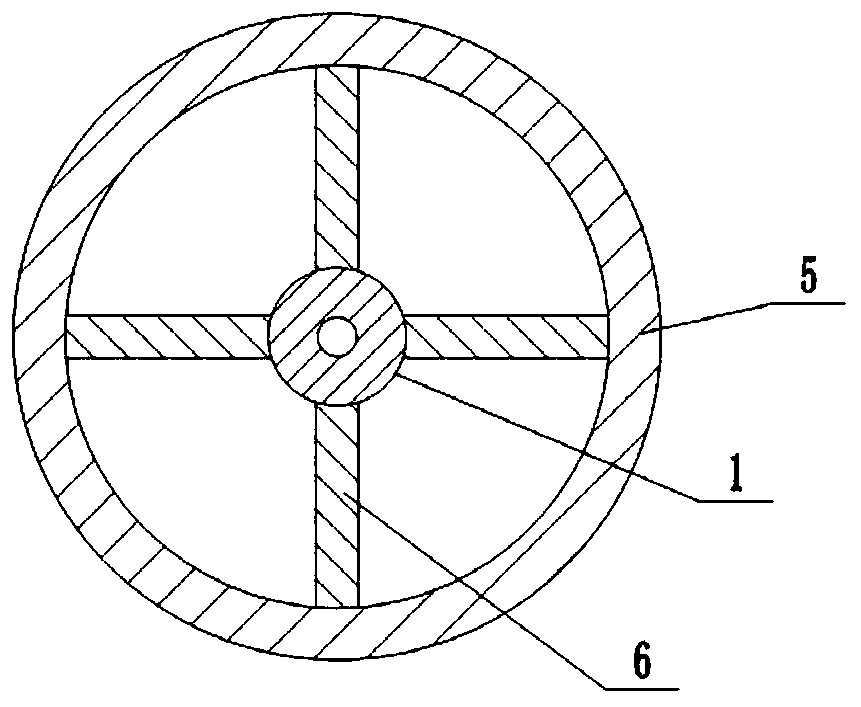

[0026] Such as figure 1 Shown: a new type of reaming equipment, including a drill rod 1 and a drive motor 2 for driving the drill rod 1 to rotate, the drive motor 2 can be a servo motor; the upper end of the drill rod 1 is connected to the output shaft of the drive motor 2, The lower end of the drill rod 1 is provided with a guide bit 3, a reaming drill bit 4 and a support ring 5 from bottom to top, the guide drill 3 is installed on the lower end of the drill rod 1, the support ring 5 is coaxially arranged with the drill rod 1, and the support ring Several support rods 6 are arranged between the inner wall of 5 and the outer wall of drill pipe 1, combined with figure 2 As shown, in this embodiment, there are four support rods 6, which are evenly distributed along the circumference of the drill pipe 1, and the two ends of the support rods 6 are respectively welded on the drill pipe 1 and the support ring 5.

[0027] The hole reaming equipment also includes a casing 7, the cas...

Embodiment 2

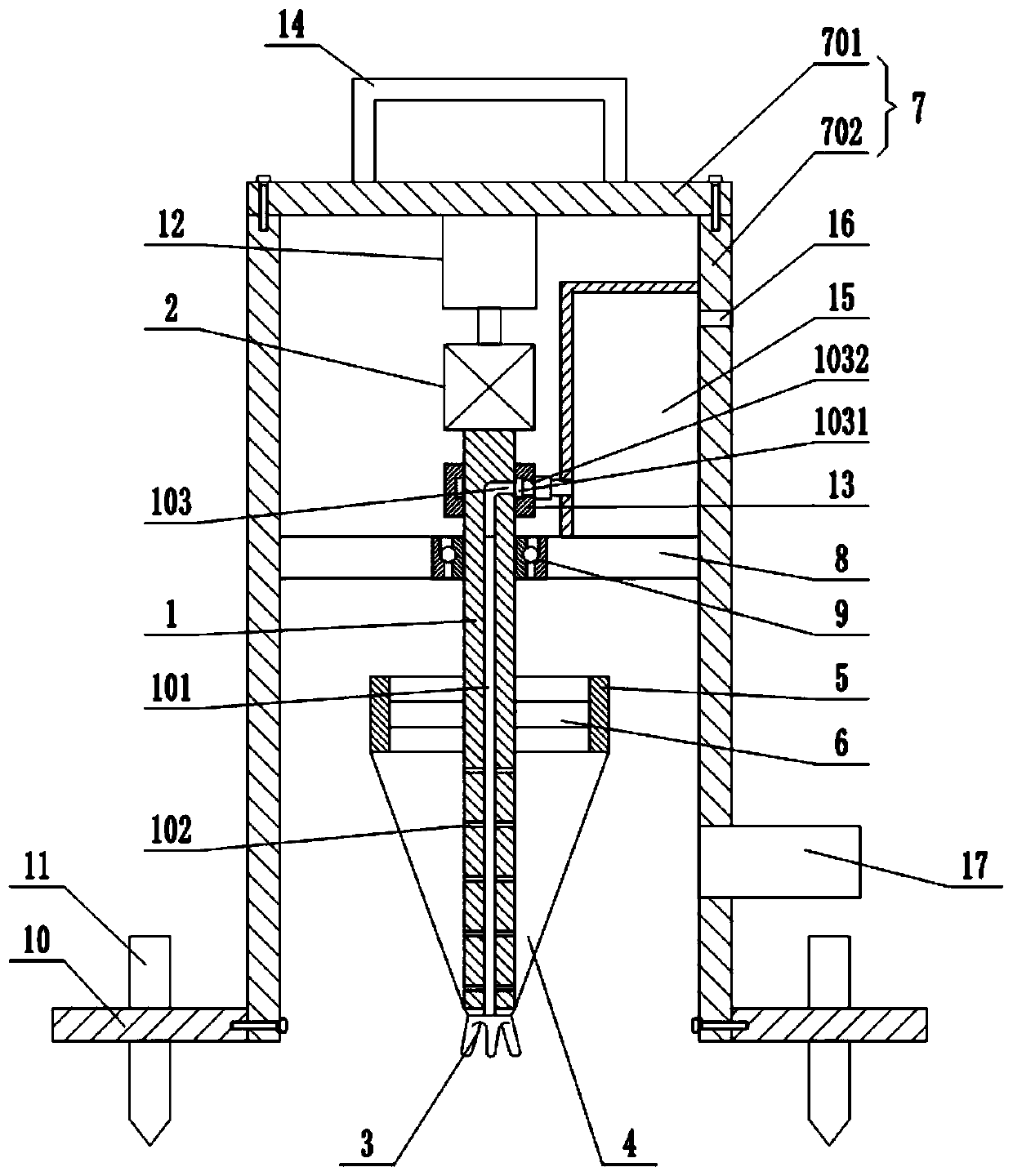

[0036] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that: a handle 14 is provided on the top wall 702 of the housing, which is convenient for lifting and operating; a water tank 15 is provided in the chamber, and the water inlet of the water tank 15 and the guide sleeve 13 1032 are connected through water pipes, and the water injection port 16 on the side wall 701 of the housing is connected with the water tank 15; the box body of the water tank 15 is a metal plate, which can be made of copper plate. The metal plate has good thermal conductivity, absorbs heat and dissipates heat quickly, and the water in the water tank 15 can absorb the heat emitted by the driving motor 2, which helps to cool down and dissipate heat to the driving motor 2, avoids the excessive operating temperature of the driving motor 2, and improves its service life.

Embodiment 3

[0038] Such as Figure 4 As shown, the difference between the present embodiment and the second embodiment is that: the outer wall of the support ring 5 is provided with a number of evenly distributed protruding teeth 501, and the protruding teeth 501 can perform secondary repairs on the hole wall to make the well wall smoother; The outer wall of the ring 5 is provided with a number of diversion grooves 502 distributed along its circumferential direction, the length direction of the diversion grooves 502 is parallel to the axial direction of the support ring 5, and the arrangement of the diversion grooves 502 facilitates the discharge of mud generated during the reaming process. Sand gravel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com