A sample color dithering method of polyester/cellulose fiber blended fabric

A technology of cellulose fibers and blended fabrics, which is applied in the field of fabric dyeing, and can solve the problems of impermeable dyeing properties and uses, large color difference, economic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

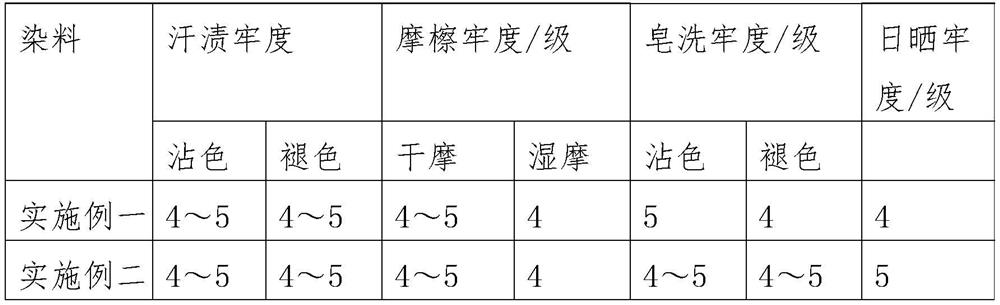

Examples

Embodiment 1

[0024] Polyester and adhesive mixed textile sample (52% polyester component, 48% adhesive ingredient)

[0025] (1) Cut the customer sample, dissolve the cotton, water washing, alkali, and to neutral, dry, used as a polyester, and the dyeing prescription and process of the polyester portion in the blended fabric is initially determined. condition;

[0026] (2) Take a weight of 5 grams and the blended fabric after the same specification is the same as the sample specification, and the dyeing liquid is prepared according to the dyeing of the polyester, and the pH of the dye is adjusted, and the microwave oven is stained, and the water is washed back after dyeing;

[0027] (3) Tailor the blended fabric of the above staining, dissolve cellulose fibers, water washing, alkali, and to neutral, dry;

[0028] Using the color difference of the color measurement instrument and the standard color sample, if the color difference is less than 0.6, the polyester portion is successfully pulled, an...

Embodiment 2

[0041] Polyester and cotton mixed textile samples (60% polyester component, 40% cotton ingredient)

[0042] (1) Cut a small piece of customer sample (customer sample is cotton cellulose blanks), dissolve with aqueous sulfuric acid solution, water washing, alkali, and to neutral, dry, used as polyester color standard color Sample, analyzed the color sample, preliminary determination of polyester dyeing prescription and process conditions: dispersion dye 2.0g / L, chelate dispersant 1.8 g / L;

[0043] (2) Take the fabric (5 grams) of the fabric (or 5 grams) of the same specification (or same as the actual production), according to the premiere polyester dyeing, adjusting the pH of the dyeing liquid is 5.5, and the microwave oven is stained 5min;

[0044] (3) Dyeing, dry, dry, dissolved cotton fibers, water washing, alkali, and to neutral, dry, and utilized the color difference with the above polyester standard color sample with a measuring instrument test (or visual inspection). ;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com