Method for preparing multi-stage pore Y molecular sieve through H4EDTA-NaOH co-treatment

A molecular sieve and multi-stage pore technology, applied in the field of molecular sieves, can solve the problems of insufficient mesopore volume and small mesopore specific surface area, and achieve the effects of reducing total acid content, L acid content, and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

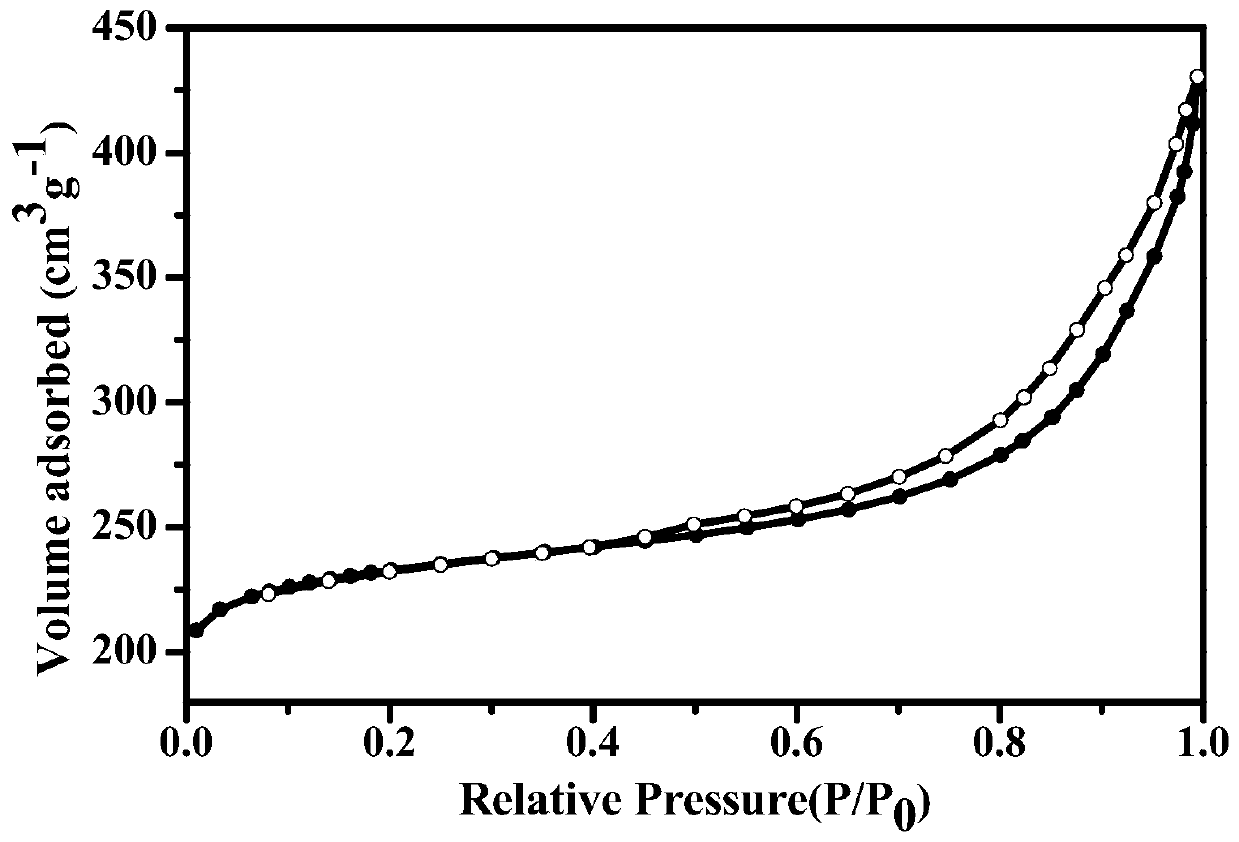

Image

Examples

Embodiment 1

[0017] Example 1: H 4 Method for preparing hierarchically porous Y molecular sieves by co-processing EDTA-NaOH (1)H 4 EDTA solution acid treatment: 100ml of distilled water and H 4 EDTA was added into a three-necked flask to form 0.11mol / L of H 4 EDTA aqueous solution, weigh 6.8g of NaY molecular sieves. Heat the three-neck flask in silicone oil. When the temperature rises to 80°C, add NaY molecular sieve, reflux and stir for 6 hours, and then filter with suction. Filter the solution with hot distilled water until pH = 7. Put the obtained solid molecular sieve in Dry in an oven at 120°C for 6h, and bake in a muffle furnace at 500°C for 6h.

[0018] (2) NaOH solution alkali treatment: use deionized water to configure NaOH solution with a concentration of 0.4mol / L, put the acid-treated sample into a three-necked flask, and add NaOH solution according to the ratio of 1g sample to 25ml NaOH solution, Under the condition of water bath at 65°C, stir for 30min; cool down the solu...

Embodiment 2

[0020] Example 2: H 4 Method for preparing hierarchically porous Y molecular sieves by co-processing EDTA-NaOH

[0021] (1)H 4 EDTA solution acid treatment: 100ml of distilled water and H 4 EDTA was added into a three-necked flask to form 0.17mol / L of H 4 EDTA aqueous solution, weigh 6.8g of NaY molecular sieves. Heat the three-necked flask in silicone oil. When the temperature rises to 65°C, add NaY molecular sieve, reflux and stir for 6 hours, and then filter with suction. Filter the solution with hot distilled water until pH = 7. Put the obtained solid molecular sieve in Dry in an oven at 120°C for 6h, and bake in a muffle furnace at 500°C for 6h.

[0022] (2) NaOH solution alkali treatment: use deionized water to configure NaOH solution with a concentration of 0.8mol / L, put the acid-treated sample into a three-necked flask, and add NaOH solution according to the ratio of 1g sample to 25ml NaOH solution, Under the condition of water bath at 80°C, stir for 30min; cool d...

Embodiment 3

[0024] Example 3: H 4 Method for preparing hierarchically porous Y molecular sieves by co-processing EDTA-NaOH (1)H 4 EDTA solution acid treatment: 100ml of distilled water and H 4 EDTA was added into a three-necked flask to form 0.14mol / L of H 4 EDTA aqueous solution, weigh 6.8g of NaY molecular sieves. Heat the three-necked flask in silicone oil. When the temperature rises to 65°C, add NaY molecular sieve, reflux and stir for 6 hours, and then filter with suction. Filter the solution with hot distilled water until pH = 7. Put the obtained solid molecular sieve in Dry in an oven at 120°C for 6h, and bake in a muffle furnace at 500°C for 6h.

[0025] (2) NaOH solution alkali treatment: use deionized water to configure NaOH solution with a concentration of 0.4mol / L, put the acid-treated sample into a three-necked flask, and add NaOH solution according to the ratio of 1g sample to 25ml NaOH solution, Under the condition of water bath at 95°C, stir for 30min; cool down the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com