Composite molecular sieve catalyst for methanol to gasoline and preparation method thereof

A compound molecular sieve and methanol-to-gasoline technology, applied in the field of catalysis, can solve the problems of expensive raw materials, unsuitable for industrialization, decreased mechanical strength of molecular sieve catalysts, etc., and achieve the effects of improving mesoporous specific surface area, improving performance and improving mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

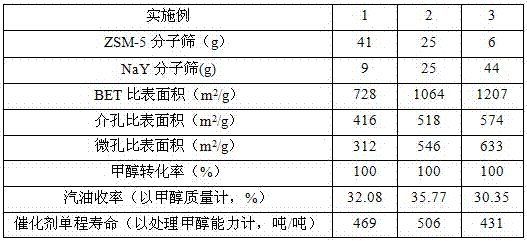

[0026] The mass ratio of embodiment 1-3 ZSM-5 molecular sieve and NaY molecular sieve

[0027] a. Weigh ZSM-5 molecular sieve (silicon-aluminum ratio 26.87, BET specific surface area 364 m 2 / g, micropore specific surface area 298 m 2 / g, the mesopore specific surface area is 66 m 2 / g) and NaY molecular sieve (silicon-aluminum ratio 3.28, BET specific surface area 703m 2 / g, micropore specific surface area 598 m 2 / g, mesopore specific surface area 105 m 2 / g), added to the mixed alkali aqueous solution of tetrapropylammonium bromide and sodium hydroxide, (ZSM-5 molecular sieve + NaY molecular sieve), tetrapropyl quaternary ammonium salt, inorganic alkali and water mass ratio is 50:135 :40:1000, stirred evenly at room temperature, put into a sealed reaction kettle, reacted for 48 hours at a temperature of 170° C. and autogenous pressure, and obtained an alkali-treated composite molecular sieve;

[0028] b. Filtrating, washing, and drying the alkali-treated composite mole...

Embodiment 4~9

[0035] Examples 4-9 (ZSM-5 molecular sieve+NaY molecular sieve), tetrapropylammonium bromide, sodium hydroxide and water in different mass ratios

[0036] Catalyst is prepared by the method for embodiment 2, and difference with embodiment 2 is only to change (ZSM-5 molecular sieve+NaY molecular sieve), the mass proportion of tetrapropyl ammonium bromide, sodium hydroxide and water, and embodiment The comparison results of 2 are shown in Table 2.

[0037] Table 2 (ZSM-5 molecular sieve + NaY molecular sieve), tetrapropylammonium bromide, sodium hydroxide and water catalyst data in different mass ratios

[0038]

[0039] If the concentration of the mixed alkali aqueous solution is too small, a certain alkali treatment effect cannot be achieved, and the number of mesopores formed is too small; if the concentration is too high, the pore structure of the original molecular sieve will easily collapse.

[0040] As can be seen from the above table, the mass ratio (ZSM-5 molecular si...

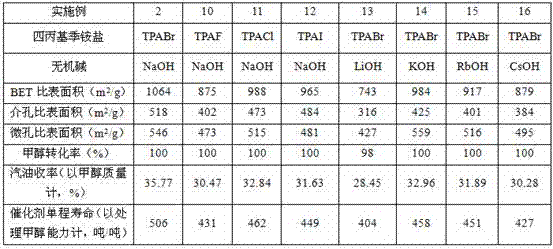

Embodiment 10~16

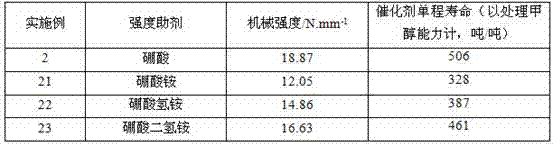

[0041] Embodiment 10~16 different mixed alkaline aqueous solutions

[0042] Catalyst is prepared by the method for embodiment 2, and difference with embodiment 2 is only to change the kind of tetrapropyl quaternary ammonium salt and inorganic base in the mixed alkali, and the comparative result of embodiment 2 is shown in table 3.

[0043] Table 3 Catalyst data prepared by different mixed alkali aqueous solutions

[0044]

[0045] It can be seen from the above table that when tetrapropylammonium bromide and sodium hydroxide are selected as the mixed base, the obtained multi-order molecular sieve has the best channel distribution, the highest gasoline yield and the longest service life of the catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com