Autoclaved curing production process of aerated concrete blocks

A technology of aerated concrete and autoclave curing, applied in manufacturing tools, applications, ceramic molding machines, etc., can solve problems such as poor environment, impact on production efficiency, and insufficient optimization, and achieve thermal insulation and shock resistance, which is conducive to environmental protection, The effect of increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

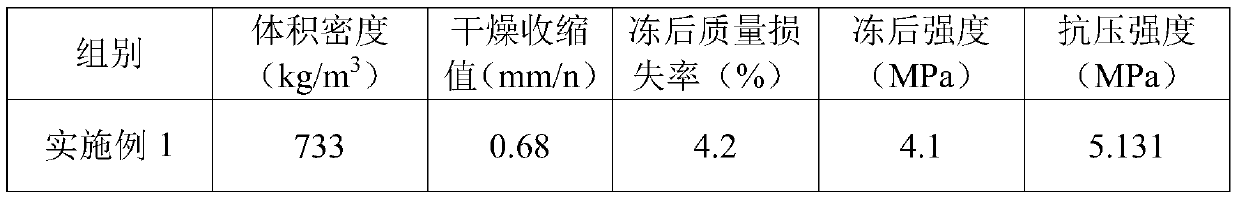

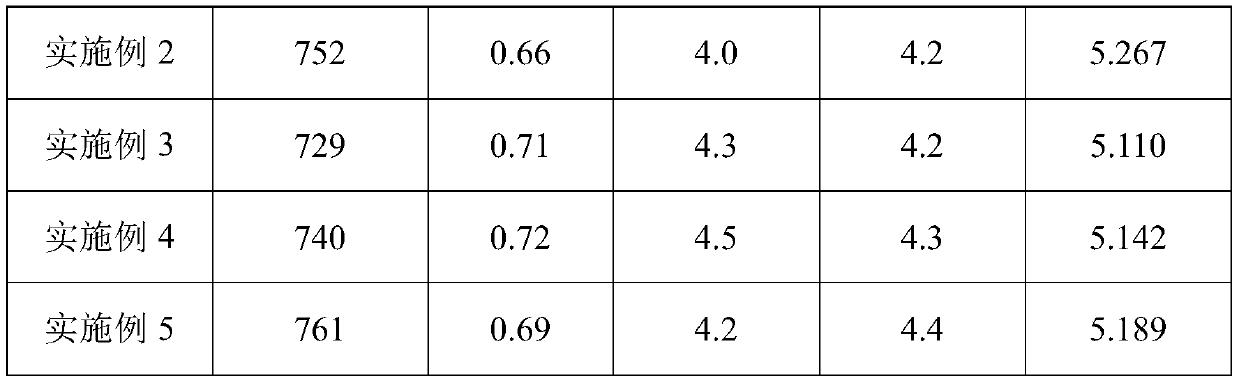

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solution of the present invention is described in detail below, but it should not be construed as limiting the scope of implementation of the present invention.

[0030] The invention provides an autoclaved curing aerated concrete block production process, comprising the following steps:

[0031] (a) making a mixed slurry of artificial quartz stone waste, sand, lime, cement, gypsum and water;

[0032] (b) Inject steam into the mixed slurry to raise the temperature of the mixed slurry to 40°C-45°C, stir for 3min-4min, add an air-generating agent, stir for ≤40s, and make a pouring slurry;

[0033] (c) pouring the pouring slurry into the mould, and performing gas generation and initial setting to form a green body;

[0034] (d) Demoulding, cutting and autoclaving curing procedures are carried out on the body to make a finished aerated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com