Preparing method for hydrotreating catalyst with desulfurization activity

A hydrogenation treatment and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve high desulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

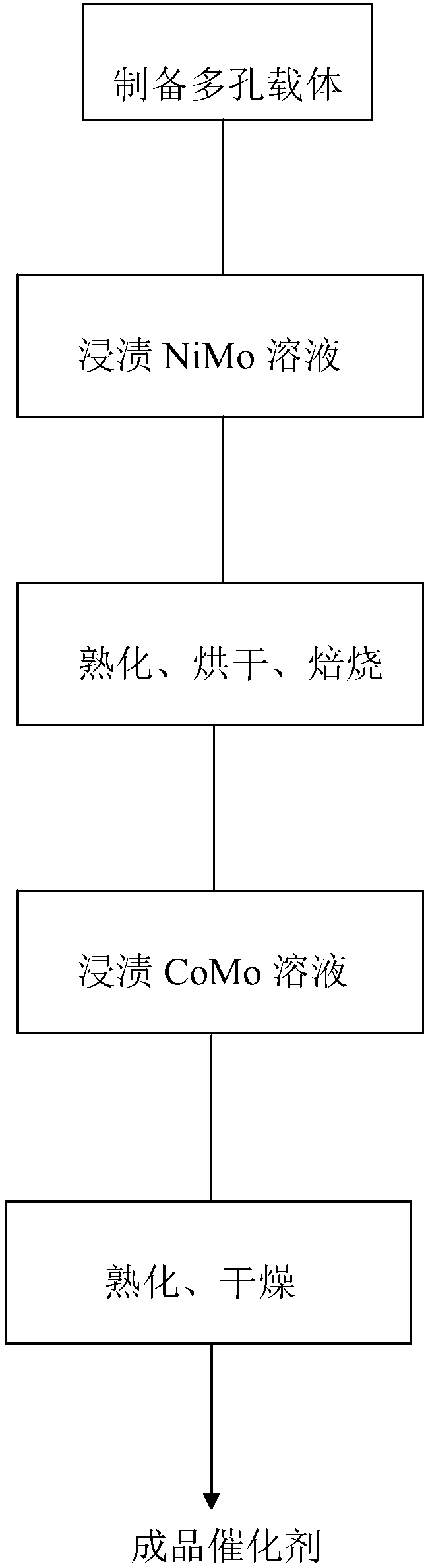

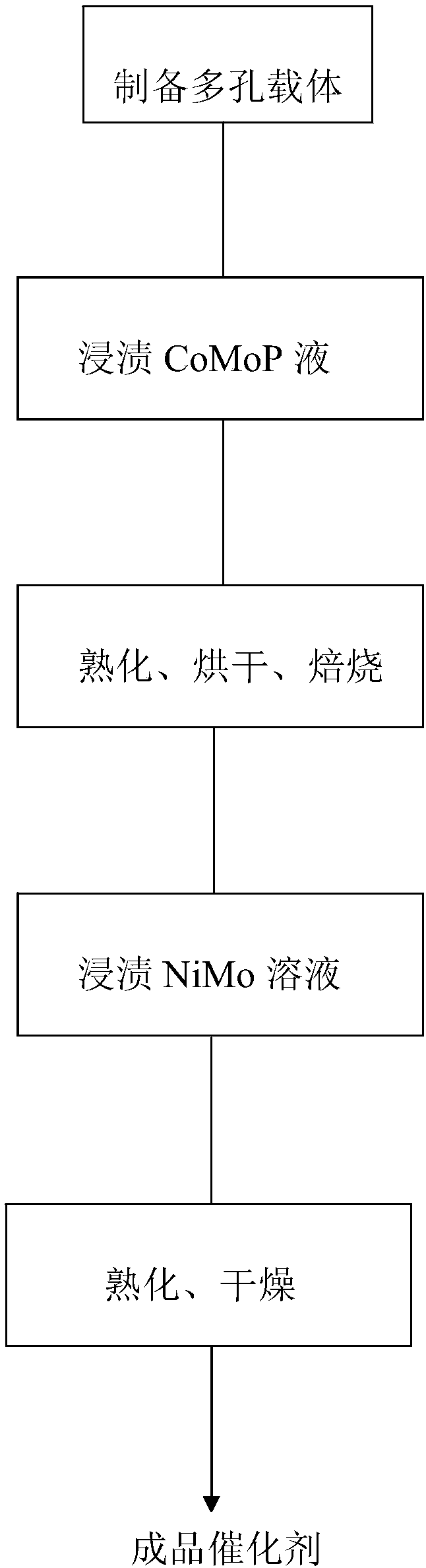

[0030] A preparation method of a hydrotreating catalyst with desulfurization activity, comprising the following steps:

[0031] Step 1, preparing a macroporous carrier of phosphorus-containing alumina or phosphorus-modified alumina material;

[0032] Step 2, impregnating the porous carrier with a type I metal solution, aging, drying, and roasting to obtain a catalyst precursor, and the type I metal solution is a NiMo solution containing Ni and Mo elements;

[0033] Step 3, the catalyst precursor is impregnated with the type II metal solution containing organic additives, then matured and dried, without going through the roasting process, to obtain the final catalyst; the type II metal solution is a CoMo solution containing Co and Mo elements, I The metalloid solution and the II metal solution are not NiMo solution or CoMo solution at the same time.

[0034] In the preparation method of the hydrotreating catalyst with desulfurization activity described in the present invention...

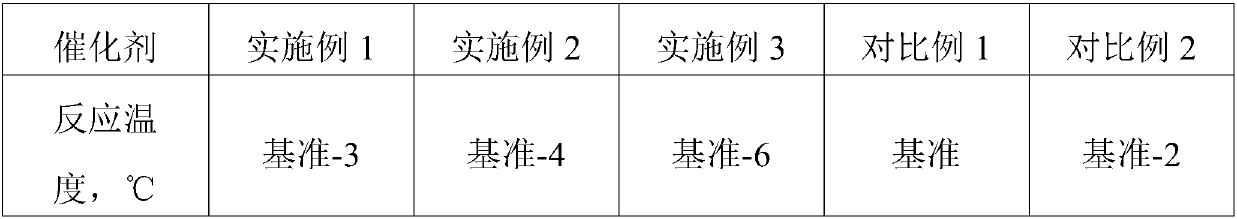

Embodiment 1

[0043] Embodiment 1: preparation I / II type Ni / CoMo catalyst C3 (according to the present invention)

[0044] Step 1: Use pseudo-boehmite to extrude, dry, and roast to make clover-shaped A1 2 o 3 carrier. Take 70g of prepared A1 2 o 3 The carrier was impregnated with 5.0 g of 85% phosphoric acid, and after curing for 4 hours, it was dried at 120° C. for 3 hours to obtain a phosphoric acid-modified alumina carrier.

[0045] Step 2, dissolving ammonium heptamolybdate (15 g) and nickel nitrate hexahydrate (11.6 g) in 50 ml of ammonia water (6%) solution to prepare NiMo solution. NiMo solution was added to the above-mentioned phosphorus-modified carrier, after impregnation, the extrudate was aged at room temperature for 6 hours, dried at 120°C overnight, and calcined at 400°C for 4 hours to obtain a catalyst precursor.

[0046] Step 3, dissolving ammonium heptamolybdate (15g) and cobalt nitrate hexahydrate (18.8g) in an aqueous solution of citric acid to prepare a uniform and ...

Embodiment 2

[0047] Embodiment 2 prepares I / II type Co / NiMo catalyst C2 (according to the present invention)

[0048] Step 1: Use pseudo-boehmite to extrude, dry, and roast to make clover-shaped A1 2 o 3 carrier. Take 70g of prepared A1 2 o 3 The carrier was impregnated with 5.0 g of 85% phosphoric acid, and after curing for 4 hours, it was dried at 120° C. for 3 hours to obtain a phosphoric acid-modified alumina carrier.

[0049] Step 2, dissolving ammonium heptamolybdate (15 g) and cobalt nitrate hexahydrate (18.8 g) in 50 ml of ammonia water (6%) solution to prepare a CoMo solution. The CoMo solution was added to the above-mentioned phosphorus-modified carrier, and after impregnation, the extrudate was aged at room temperature for 6 hours, dried at 100°C overnight, and calcined at 550°C for 4 hours to obtain a catalyst precursor.

[0050] Step 3, dissolving ammonium heptamolybdate (15g) and nickel nitrate hexahydrate (11.6g) in an aqueous solution of citric acid to prepare a uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com