Low-temperature electrolyte and lithium battery using same

An electrolyte and lithium battery technology, applied in the field of lithium-ion batteries, to achieve high ion conductivity, good compatibility, excellent low-temperature discharge and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

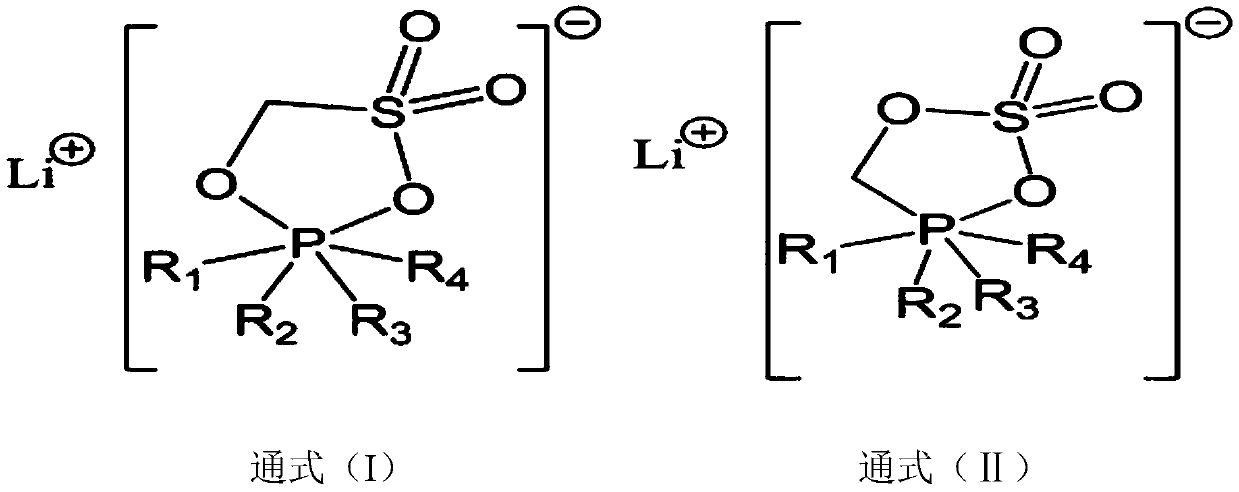

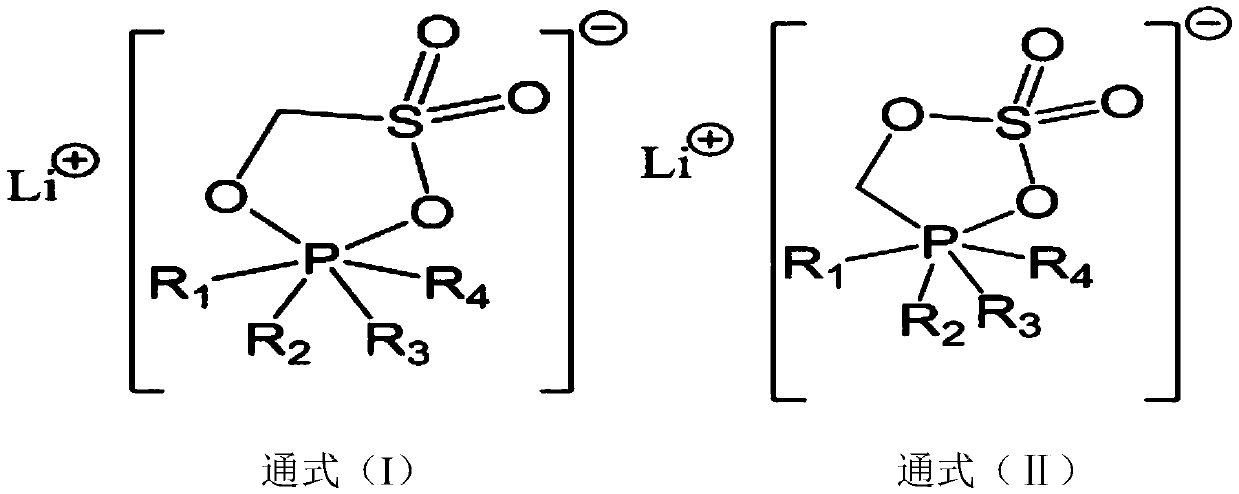

Method used

Image

Examples

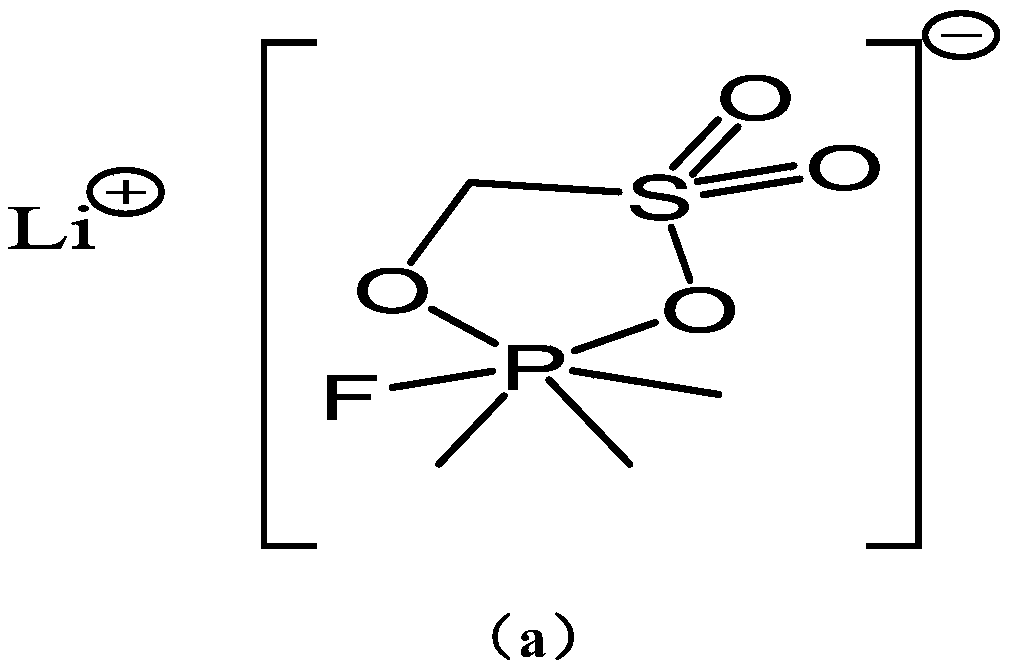

Embodiment 1

[0023] Electrolyte preparation: In a glove box (moisture <0.1ppm, oxygen <0.1ppm) filled with argon, take dimethyl carbonate, ethylene carbonate, ethyl methyl carbonate, propylene carbonate, which account for 85% of the total mass of the electrolyte Ethyl acetate organic mixed solution, the mass ratio of dimethyl carbonate, ethylene carbonate, ethyl methyl carbonate, and ethyl propionate is 1:3:3:3; then add an additive accounting for 1% of the total mass of the electrolyte to the mixed solution Vinylene carbonate and fluoroethylene carbonate, the mass ratio of vinylene carbonate to fluoroethylene carbonate is 1:1, and finally slowly add 14% of the total mass of the electrolyte to the mixed solution. Lithium phosphate (a), after being stirred evenly, the lithium-ion battery electrolyte of Example 1 of the present invention was obtained.

[0024]

[0025] Use the electrolytic solution of this embodiment to prepare lithium ion battery:

[0026] Preparation of positive electr...

Embodiment 2

[0030] Electrolyte preparation: In a glove box (moisture <0.1ppm, oxygen <0.1ppm) filled with argon, take dimethyl carbonate, ethylene carbonate, ethyl methyl carbonate, propylene carbonate, which account for 85% of the total mass of the electrolyte Ethyl acetate organic mixed solution, the mass ratio of dimethyl carbonate, ethylene carbonate, ethyl methyl carbonate, and ethyl propionate is 1:3:3:3; then add an additive accounting for 1% of the total mass of the electrolyte to the mixed solution Vinylene carbonate and fluoroethylene carbonate, the mass ratio of vinylene carbonate to fluoroethylene carbonate is 1:1, and finally slowly add 14% of the total mass of the electrolyte to the mixed solution. Lithium phosphate (b), after being stirred evenly, the lithium-ion battery electrolyte of Example 2 of the present invention was obtained.

[0031]

[0032] The electrolyte solution of this example is used to prepare a lithium ion battery, and the preparation method is the same...

Embodiment 3

[0034] Electrolyte preparation: In a glove box filled with argon (moisture <0.1ppm, oxygen <0.1ppm), take dimethyl carbonate, ethylene carbonate, methyl ethyl carbonate, propionic acid, which account for 85% of the total mass of the electrolyte Ethyl organic mixed solution, the mass ratio of dimethyl carbonate, ethylene carbonate, ethyl methyl carbonate and ethyl propionate is 1:3:3:3; then add 1% of the total mass of electrolyte carbonic acid to the mixed solution Vinylene ester and fluoroethylene carbonate, the mass ratio of vinylene carbonate to fluoroethylene carbonate is 1:1, and finally, slowly add alkyl sulfur-containing oxygen-containing fluorophosphoric acid to the mixed solution, accounting for 14% of the total mass of the electrolyte Lithium (c), after stirring evenly, the lithium-ion battery electrolyte of Example 3 of the present invention was obtained.

[0035]

[0036] The electrolyte solution of this example is used to prepare a lithium ion battery, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com