A Prediction Method of Surface Subsidence of Shield Excavation Face Considering Cutterhead Compression Stratum Deformation

A technology for surface subsidence and prediction methods, applied in design optimization/simulation, geometric CAD, etc., can solve problems such as failure to consider impact, and achieve the effect of clear implementation process, high calculation accuracy, and improved prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] In this embodiment, the spoke-type shield cutter head used in a section tunnel of Beijing Metro Line 14 is used as an example for illustration.

[0094] A method for predicting surface subsidence of a shield excavation face considering the formation deformation caused by cutter head extrusion, comprising the following steps:

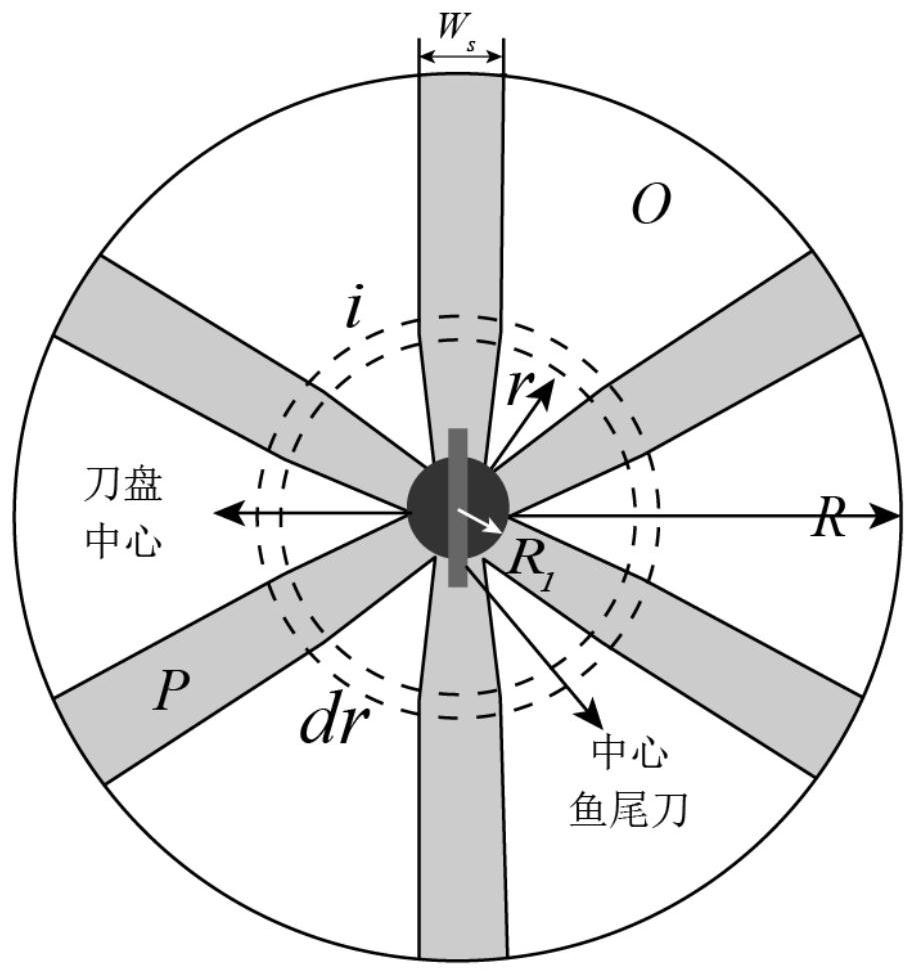

[0095] Step (1): Simplify the cutterhead model. According to the actual configuration of the shield cutter head of this project, scrapers, hobs, cutters, profiling knives and other knives outside the central area of the shield are removed, and the panel, spokes and center large-sized fishtail knife are retained to form a simplified calculation diagram of the cutter head Such as Image 6 shown.

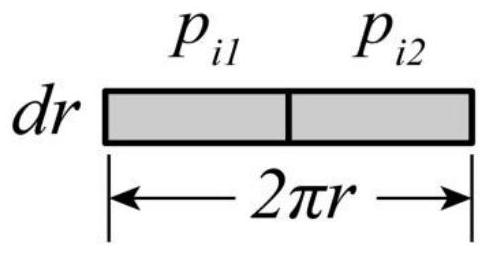

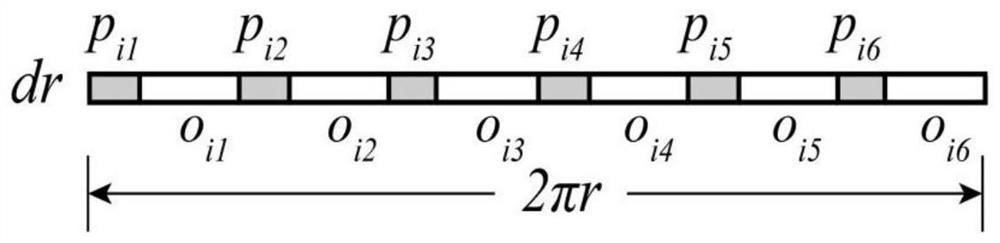

[0096] Step (2): Take ring differential for the cutterhead model. Divide the circular cutter head into circular microelements, each microelement thickness is dr, and the radius of the circular microelement is r; if the ring microelement width dr is in...

Embodiment 2

[0119] The radial plate shield cutter head used in the construction of a cross-sea tunnel project in Guangdong is used as an example to illustrate.

[0120] A method for predicting surface subsidence of a shield excavation face considering the formation deformation caused by cutter head extrusion, comprising the following steps:

[0121] Step (1): Simplify the cutter head model. In view of the actual configuration of the shield cutter head of this project, scrapers, hobs, cutters, profiling knives and other knives outside the central area of the shield are removed, and the panel, spokes and center hob of the cutter head are retained to form a simplified calculation diagram of the cutter head. Figure 7 shown.

[0122] Step (2): Take a circular micro-element for the cutter head, each micro-element has a thickness of dr, and the distance between the ring and the center is r; expand the micro-element circle to approximate a rectangular micro-element with a length of 2πr and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com