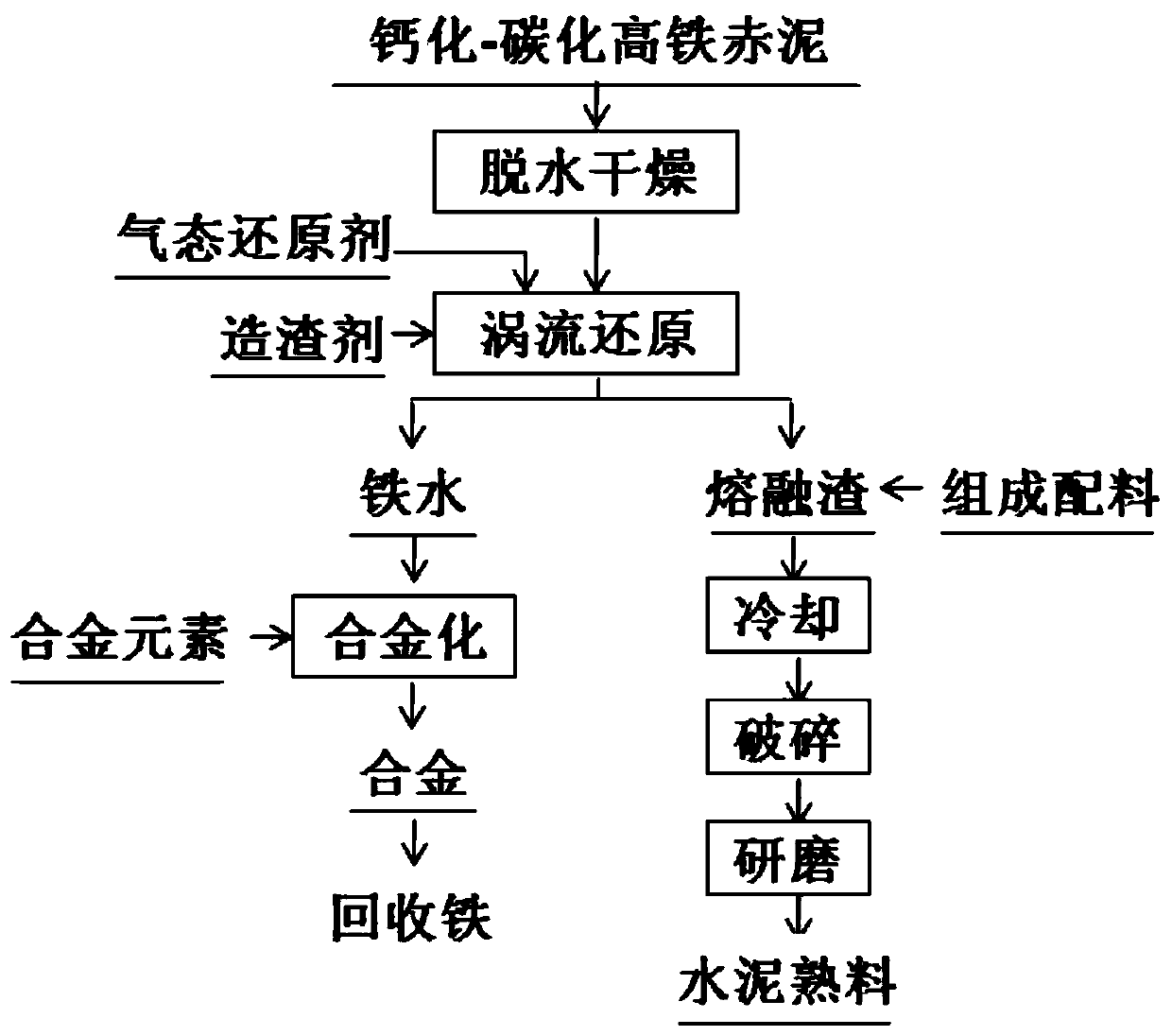

Calcified-carbonized high-iron red mud recycling iron and tailings cementation method

A technology for carbonizing high-speed iron and recovering iron, applied in cement production, reducing gas emissions, etc., can solve the problems of unutilized tailings, low product price, and long processing process, and achieves sufficient reduction kinetics conditions and monomers. High degree of dissociation, the effect of promoting mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for calcification-carbonized high-speed iron red mud recovery iron and tailings cementation, comprising the following steps:

[0045] The raw material calcified-carbonized high iron red mud includes components and mass percentages: TFe content is 30%, Al 2 O 3 Content at 12%, SiO 2 Content at 20%, Na 2 O content at 0.5%, H 2 O content 10%;

[0046] (1) dehydrating and drying the calcified-carbonized high-speed iron red mud to a moisture content of less than 1% to obtain dried red mud, and grinding the dried red mud and slag-forming agent mixture to a 0.2mm sieve and remaining 4% to form a mixture, The mixture is directly injected into the vortex center of the vortex stirring melting reduction high temperature furnace without sintering and is drawn into the molten pool. The slag-forming agents are CaO and CaF. 2 The mixture, CaO is added according to the basicity of the mixture is 1.4, CaF 2 The mass is added by 20% of the mass of CaO;

[0047] (2) Vortex...

Embodiment 2

[0051] A method for calcification-carbonized high-speed iron red mud recovery iron and tailings cementation, comprising the following steps:

[0052] The raw material calcified-carbonized high iron red mud includes components and mass percentages: TFe content is 30%, Al 2 O 3 Content at 12%, SiO 2 Content at 20%, Na 2 O content at 0.5%, H 2 O content 10%;

[0053] (1) dehydrating and drying the calcified-carbonized high iron red mud to a moisture content of less than 1% to obtain dried red mud, and grinding the dried red mud and slag-forming agent mixture to a 0.2mm sieve and remaining 1% to form a mixture, The mixture is directly injected into the vortex center of the vortex stirring melting reduction high temperature furnace without sintering and is drawn into the molten pool. The slag-forming agents are CaO and CaF. 2 The mixture, CaO is added according to the alkalinity of the mixture is 1.0, CaF 2 The mass is added by 30% of the mass of CaO;

[0054] (2) Vortex sti...

Embodiment 3

[0058] A method for calcification-carbonized high-speed iron red mud recovery iron and tailings cementation, comprising the following steps:

[0059] The raw material calcified-carbonized high iron red mud includes components and mass percentages as follows: TFe content is 20%, Al 2 O 3 Content at 8%, SiO 2 Content at 12%, Na 2 O content at 0.4%, H 2 O content 13%;

[0060] (1) dehydrating and drying the calcified-carbonized high-speed iron red mud to a moisture content of less than 1% to obtain dried red mud, and grinding the dried red mud and slag-forming agent mixture to a 0.2mm sieve and remaining 2% to form a mixture, The mixture is directly injected into the vortex center of the vortex stirring melting reduction high temperature furnace without sintering and is drawn into the molten pool. The slag-forming agents are CaO and CaF. 2 The mixture, CaO is added according to the basicity of the mixture is 1.2, CaF 2 The mass is added by 10% of the mass of CaO;

[0061] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com