High light, wear resistant and aging resistant silica gel PU printing ink and preparation method and application method thereof

An application method and anti-aging technology, applied in the field of ink, can solve the problems of poor adhesion, wear resistance and aging resistance, insufficient ink brightness, etc., and achieve chemical resistance without yellowing, good elasticity, and weather resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

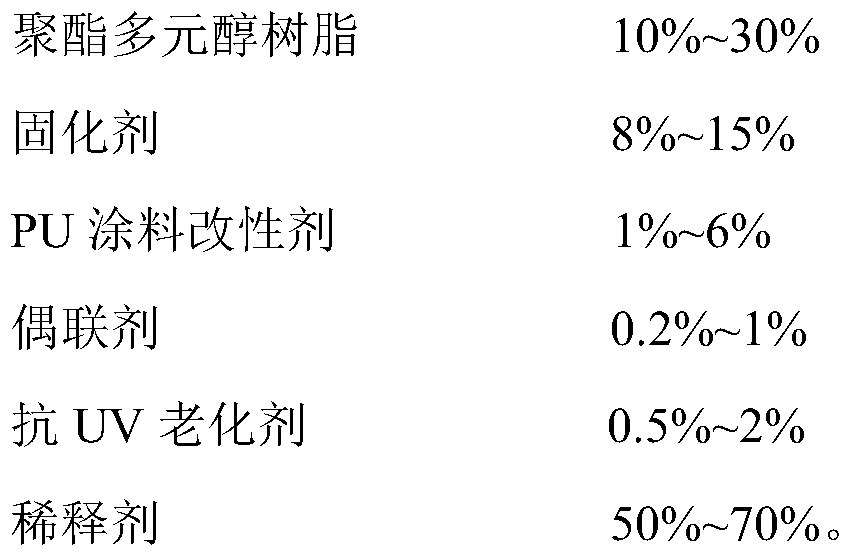

[0033] A high-gloss, wear-resistant, aging-resistant silicone PU ink, which is made of the following raw materials:

[0034]

[0035] Among them, the curing agent is blocked polyisocyanate; the PU coating modifier is 4'-diphenylmethane type bismaleimide; the coupling agent is a silane coupling agent whose model is KT-889; the diluent is butyl acetate ester.

[0036] The preparation method of above-mentioned a kind of high-gloss, wear-resisting, anti-aging silicone PU ink, it comprises the following steps:

[0037] Step 1. Weighing: Weigh the polyester polyol resin, curing agent, PU coating modifier, coupling agent, anti-UV aging agent and diluent respectively according to the formula quantity;

[0038] Step 2. Dispersion and mixing: Add the polyester polyol resin, curing agent, PU coating modifier, coupling agent, anti-UV aging agent and diluent weighed in step 1 into the container, and then disperse in a high-speed disperser for 30 minutes. After stirring evenly, the hig...

Embodiment 2

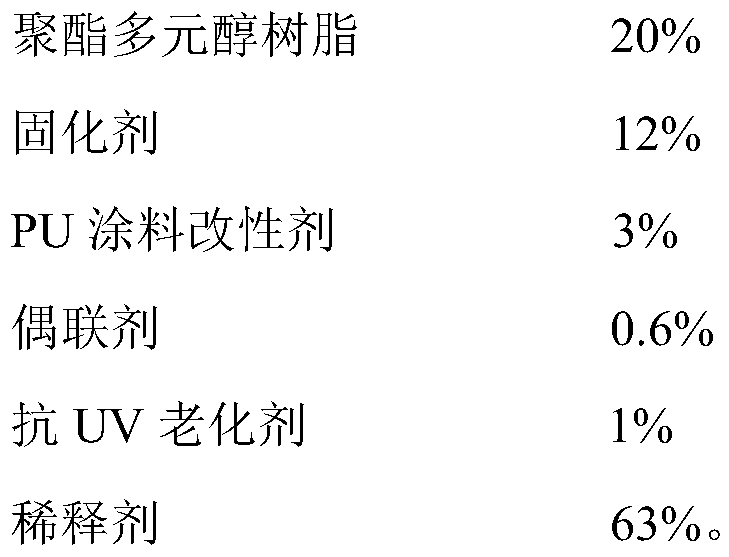

[0043] A high-gloss, wear-resistant, aging-resistant silicone PU ink, which is made of the following raw materials:

[0044]

[0045] Among them, the curing agent is blocked polyisocyanate; the PU coating modifier is 4'-diphenylmethane type bismaleimide; the coupling agent is a silane coupling agent whose model is KT-889; the diluent is butyl acetate ester.

[0046] The preparation method of above-mentioned a kind of high-gloss, wear-resisting, anti-aging silicone PU ink, it comprises the following steps:

[0047] Step 1. Weighing: Weigh the polyester polyol resin, curing agent, PU coating modifier, coupling agent, anti-UV aging agent and diluent respectively according to the formula quantity;

[0048] Step 2. Dispersion and mixing: Add the polyester polyol resin, curing agent, PU coating modifier, coupling agent, anti-UV aging agent and diluent weighed in step 1 into the container, and then disperse in a high-speed disperser for 20 minutes. After stirring evenly, the hig...

Embodiment 3

[0053] A high-gloss, wear-resistant, aging-resistant silicone PU ink, which is made of the following raw materials:

[0054]

[0055] Among them, the curing agent is blocked polyisocyanate; the PU coating modifier is 4'-diphenylmethane type bismaleimide; the coupling agent is a silane coupling agent whose model is KT-889; the diluent is butyl acetate ester.

[0056] The preparation method of above-mentioned a kind of high-gloss, wear-resisting, anti-aging silicone PU ink, it comprises the following steps:

[0057] Step 1. Weighing: Weigh the polyester polyol resin, curing agent, PU coating modifier, coupling agent, anti-UV aging agent and diluent respectively according to the formula quantity;

[0058] Step 2. Dispersion and mixing: Add the polyester polyol resin, curing agent, PU coating modifier, coupling agent, anti-UV aging agent and thinner weighed in step 1 into the container, and then disperse in a high-speed disperser for 40 minutes. After stirring evenly, the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com