Polylactic acid composition used for 3D printing, and preparation method thereof

A 3D printing and polylactic acid technology, applied in the field of 3D printing materials, can solve the problems of monotonous printing effect and inability to spray dyeing with water-based dyes, and achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A polylactic acid composition for 3D printing, which consists of 45 parts of PLA, 45 parts of PCL, 5 parts of polyurethane material, and 5 parts of nano-scale activated carbon in parts by weight.

[0020] The preparation method of described polylactic acid composition, comprises the steps:

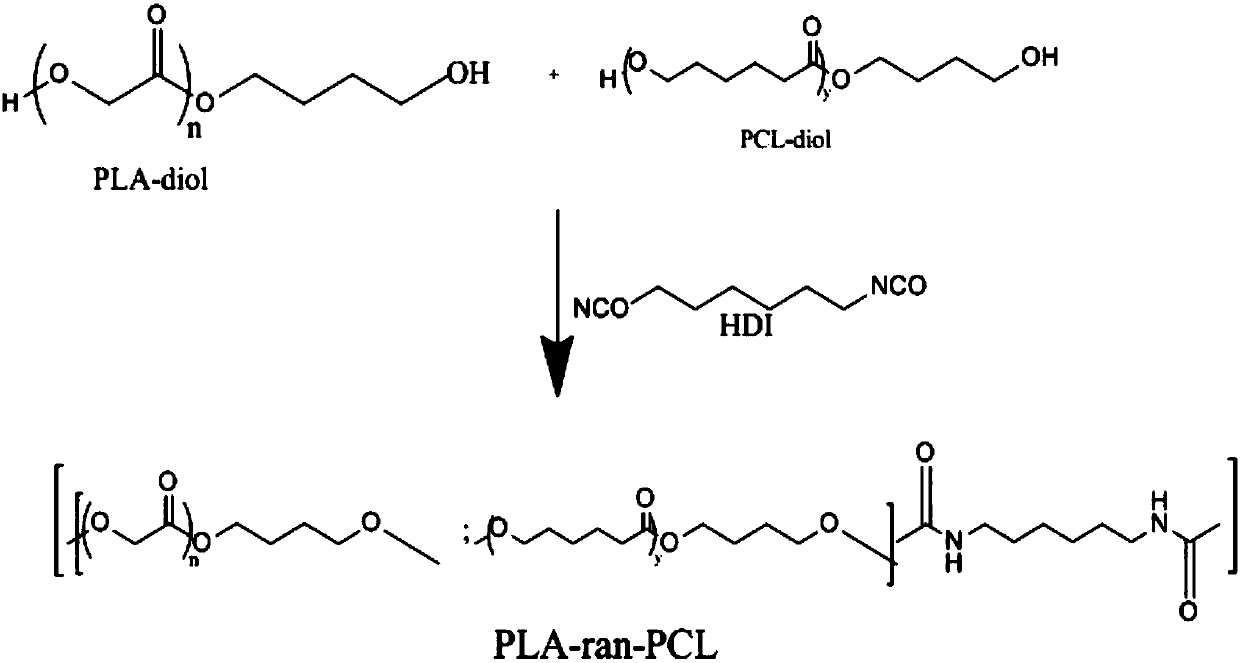

[0021] (1), the preparation of the PCL of double hydroxyl end-capping

[0022] Weigh 25g of PCL into a 500mL two-neck flask, add 250mL of chloroform, heat to 75°C, stir until fully dissolved, add 1,4-butanediol (or ethylene glycol, 1,3- transesterification reagents such as propylene glycol) and 2wt% p-toluenesulfonic acid (also can adopt the saturated fatty acid such as lauric acid, palmitic acid as catalyzer), carry out transesterification reaction, react 8-28 hour; After the reaction finishes, Cool naturally to normal temperature, then pour the solution into a separatory funnel pre-installed with 1L deionized water, filter under reduced pressure to obtain a transparent liquid, th...

Embodiment 2

[0032] A polylactic acid composition for 3D printing, which consists of 50 parts of PLA, 45 parts of PEG particles, 8 parts of polyurethane material, and 5 parts of nano-scale activated carbon in parts by weight.

[0033] The preparation method of described polylactic acid composition, comprises the steps:

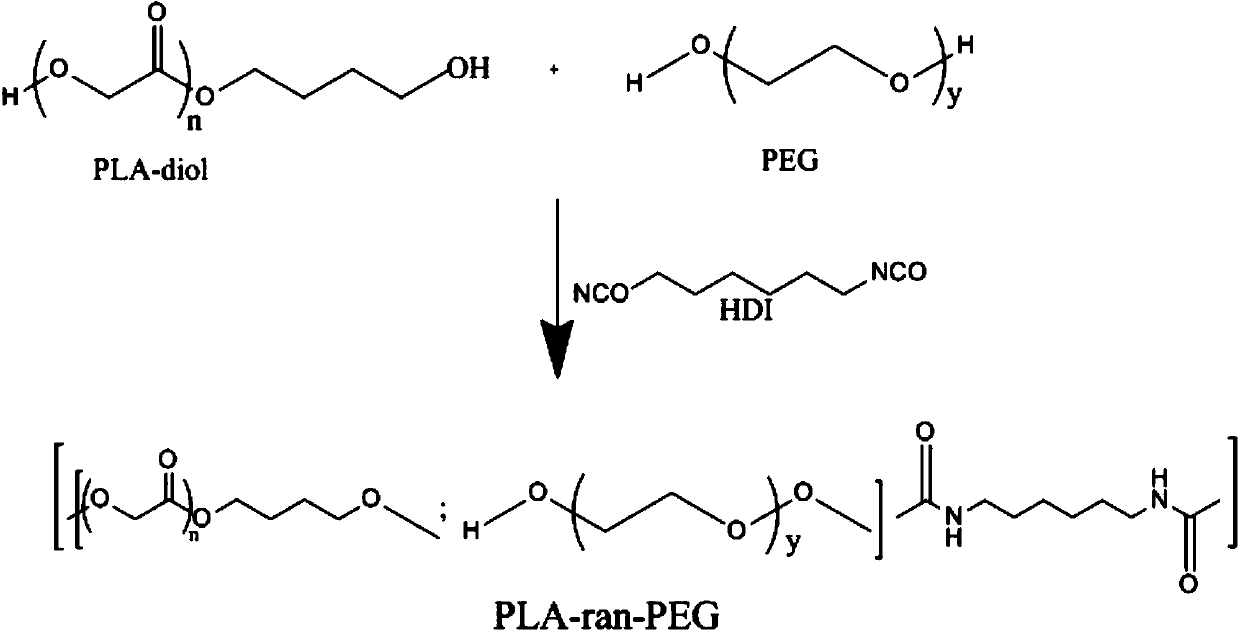

[0034] (1), the preparation of the PLA of double hydroxyl end-capping

[0035] Weigh 25g PLA in a 500mL two-necked flask, add 250mL of chloroform, heat to 75°C and stir until fully dissolved, add 5 times the molar number of ethylene glycol (ester exchange reagent) and 2wt% p-toluenesulfonic acid (catalyst ) mixed solution for transesterification reaction, reacted for 8-28 hours; after the reaction was finished, naturally cooled to normal temperature, then poured the solution into a separatory funnel pre-equipped with 1L deionized water, filtered under reduced pressure to obtain a transparent liquid, Then through rotary distillation and vacuum precipitation, the PLA-diol m...

Embodiment 3

[0043] A polylactic acid composition for 3D printing, which consists of 40 parts of PLA, 40 parts of POE, 10 parts of polyurethane material, and 10 parts of nano-scale activated carbon in parts by weight.

[0044] The preparation method of the polylactic acid composition of this embodiment is the same as that of Example 2, the difference is that the hydrophilic material of this embodiment adopts POE, and the preparation of polyurethane material in step (2) is the preparation of POE-PLA intermediate material, POE-PLA HMDI is used as linking agent in the preparation of PLA intermediate material.

[0045] The reaction formula for preparing POE-PLA intermediate material (i.e. PLA-ran-POE) in the present embodiment is as follows:

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com