A kind of color 3D printer and the method for preparing three-dimensional product thereof

A 3D printer, color technology, applied in the field of 3D printing, can solve the problems of rough surface, poor printing accuracy, poor precision and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

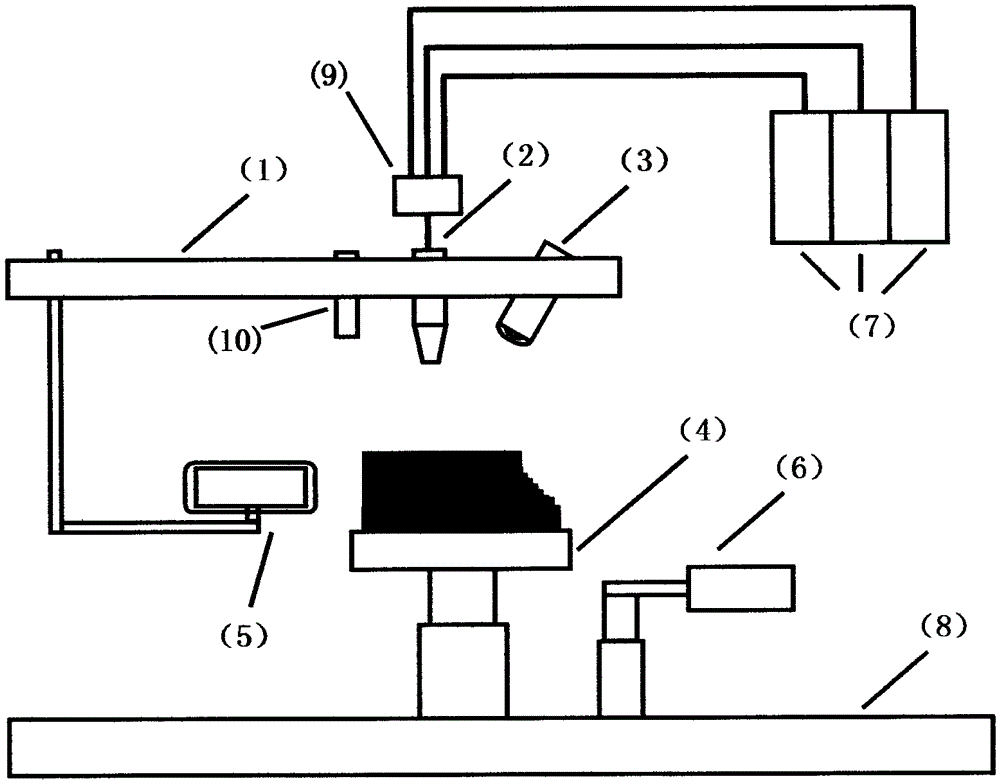

[0088] The color 3D printer involved in this embodiment is as figure 1 As shown, one nozzle, one LED ultraviolet light source and one mobile support frame are installed on the X-Y working platform, one nozzle is connected to the pre-mixer, and the connected pre-mixer is equipped with three colors of red, yellow and blue. The three UV resin supply units of the UV resin material are connected, the support table and a fixed support frame are installed on the base, and a printing thickness calibration unit is used for thickness calibration. The temperature of the UV resin storage tank was controlled at 30°C. The LED ultraviolet light source is equipped with a quartz surface concentrating sheet. The area where the light is concentrated on the printing layer is 3cm×4cm. The angle formed between the LED ultraviolet light source and the nozzle is 30°, and the concentrating position is 8cm away from the spraying position of the nozzle.

[0089] The following steps are involved in prep...

Embodiment 2

[0098] The color 3D printer involved in this embodiment is equipped with 1 nozzle, 1 LED ultraviolet light source and 1 mobile support frame on the X-Y working platform, a nozzle is connected with the pre-mixer, and the connected pre-mixer is equipped with red, Three UV resin supply units of UV resin materials in three colors of yellow and blue are connected, and the support table and a fixed support frame are installed on the base. The temperature of the UV resin storage tank was controlled at 30°C. The LED ultraviolet light source is equipped with a quartz surface concentrating sheet. The area where the light is concentrated on the printing layer is 3cm×4cm. The angle formed between the LED ultraviolet light source and the nozzle is 30°, and the concentrating position is 8cm away from the spraying position of the nozzle.

[0099] The following steps are involved in preparing a three-dimensional product that does not require a support frame:

[0100] a. Establish a three-dim...

Embodiment 3

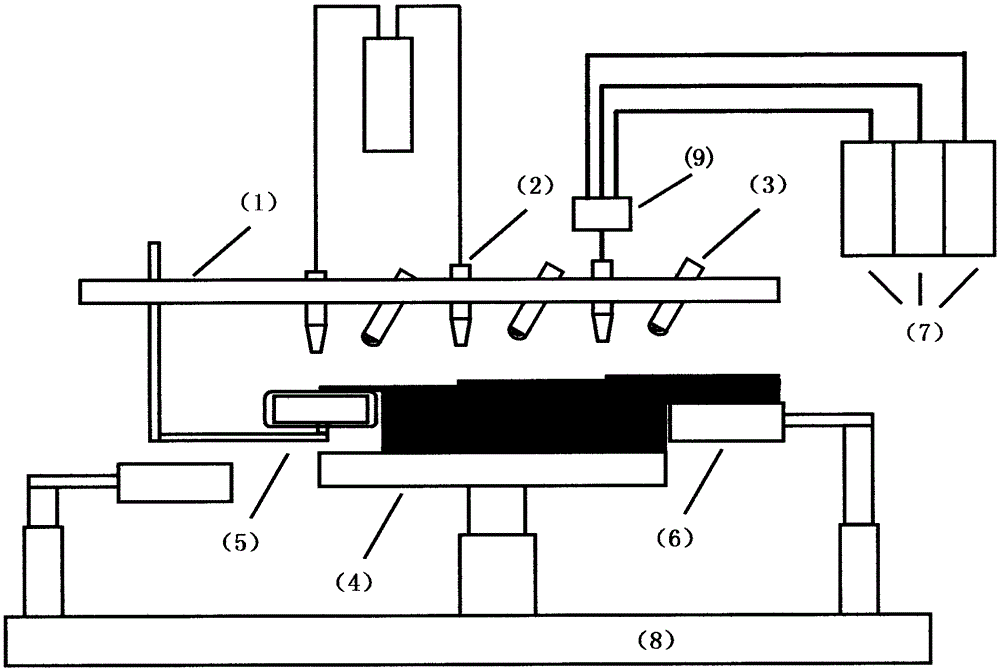

[0108] The color 3D printer involved in this embodiment is as figure 2 As shown, the X-Y working platform is equipped with 3 nozzles, 3 LED ultraviolet light sources and 1 mobile support frame, of which 1 printing nozzle and 1 LED ultraviolet light source form a printing curing unit, and the printing curing unit is arranged along the printing direction. The nozzle is connected to the pre-mixer, and the connected pre-mixer is connected to three UV resin supply units equipped with red, yellow and blue UV resin materials, and the other 2 nozzles are connected to the same white UV resin The feeding unit of the material is connected, and the support table and 2 fixed support frames are installed on the base. The temperature of the UV resin storage tank was controlled at 35°C. The LED UV light source is equipped with a quartz concentrator, and the effect obtained by concentrating the light on the printing surface is a line light source, the direction is perpendicular to the printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com