Anti-seepage cut-off underground curtain wall coal ash based impermeable material and construction method

A technology of anti-seepage material and construction method, applied in infrastructure engineering, construction and other directions, can solve the problems of insufficient strength of waterproof curtain piles, discontinuous grouting stone body, incompatibility with environmental protection policies, etc., and achieves reduction of porosity and cost. , the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

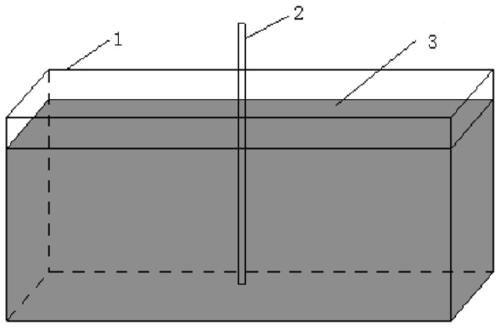

Image

Examples

Embodiment 1

[0038] Anti-seepage material raw materials (all parts are parts by weight): 40 parts of cement, 60 parts of fly ash, 5 parts of silica fume, 2 parts of bentonite, 2 parts of sodium chloride, 1.5 parts of calcium lignosulfonate, and drinking water 70 servings.

[0039] 1.1. Prepare the fly ash-based anti-seepage material for the anti-seepage and closure underground curtain wall of the open-pit mine according to the following steps:

[0040] Step 1), take drinking water, sodium chloride, and calcium lignosulfonate according to the weight of the formula and put them in a slurry mixer and stir evenly for 30 seconds;

[0041] Step 2), according to the weight of the formula, take bentonite and add it to the stirred solution in step 1) and stir evenly for 20 seconds;

[0042] Step 3), add cement, fly ash, and silica fume to the mixture stirred in step 2) respectively according to the formula weight, stir while adding, finish adding within 20 seconds, and stir evenly for 90 seconds. ...

Embodiment 2

[0050] Raw materials of anti-seepage material (all parts are parts by weight): 40 parts of cement, 60 parts of fly ash, and 70 parts of drinking water.

[0051] 2.1. Prepare the fly ash-based anti-seepage material for the anti-seepage and closure underground curtain wall of the open-pit mine according to the following steps:

[0052] Step 1), take drinking water according to formula weight;

[0053] Step 2), add cement and fly ash to the mixture after step 1) respectively according to the formula weight, stir while adding, finish adding within 20s, and stir evenly for 90s.

[0054] 2.2. Pouring underground curtain wall for anti-seepage and interception in open-pit mine:

[0055] The mud retaining wall is used in the process of forming the groove of the anti-seepage closure curtain wall, and the specific gravity of the mud in the groove section is 1.08g / cm 3 Around, the tank bottom mud may reach 1.2g / cm 3 ;Concrete according to the following steps:

[0056] Step 1), after t...

Embodiment 3

[0061] Raw materials of anti-seepage material (all parts are parts by weight): 40 parts of cement, 60 parts of fly ash, 2 parts of bentonite, 1.5 parts of calcium lignosulfonate, and 70 parts of drinking water.

[0062] 3.1. Prepare the fly ash-based anti-seepage material for the anti-seepage and closure underground curtain wall of the open-pit mine according to the following steps:

[0063] Step 1), take drinking water and calcium lignosulfonate according to the weight of the formula and place them in a slurry mixer and stir evenly for 30 seconds;

[0064] Step 2), according to the weight of the formula, take bentonite and add it to the stirred solution in step 1) and stir evenly for 20 seconds;

[0065] Step 3), respectively add cement and fly ash to the mixture stirred in step 2 according to the formula weight, stir while adding, finish adding within 20 seconds, and stir evenly for 90 seconds.

[0066] 3.2. Pouring underground curtain wall for anti-seepage and interception...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com